George Korbetis and Dimitris Georgoulas from Beta CAE Systems describe how a spade rudder was subjected to a design optimization process in order to improve its strength and behaviour. The analysis led to significant changes to its shape and shell thickness

1. Introduction

The use of the finite element analysis (FEA) becomes increasingly popular in marine design, since it[ds_preview] can give us valuable information on the strength, hydrodynamics, and model behavior of complicated parts and assemblies. However, it is always time-consuming to set up and standardize a simulation process within the design process. The pre- and post- processors of Beta CAE Systems, Ansa and ETA provide sophisticated tools in order to facilitate the FEA process. Time-consuming tasks like meshing, model simplification and mesh quality improvement have been replaced by automated processes which save a lot of engineer working hours. Additionally, such tools guide the engineer to set up the model in the most proper way and help him to overcome any human errors.

This article demonstrates the suggested process of the definition of a strength analysis and the application of the multi-objective optimization during the design process on a ship’s rudder. A simplified CFD analysis calculates the maximum force applied on the rudder’s surface. The calculated force is taken as the loading condition for the rudder’s structural analysis. The static analysis is set up using automated processes like the results mapping, the contact pair definition and the batch meshing which are provided by Ansa. Model shape parameterization is performed by Ansa’s Morphing Tool and the optimization task and different design variables are defined to control the model. As a final step a multi-objective optimization is performed to improve model behavior.

2. Problem definition

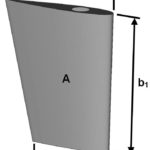

The case study model is a spade rudder with rudder trunk of a handysize class double skin bulk carrier. The ship’s length is 169 m and its maximum velocity 15 knots. When the ship is fully loaded the whole rudder and skeg are submerged beneath the sea. The rudder cross section is NACA 0015 and its main dimensions are x1=3,56, x2=5,05, b=6,2 and A=26,7 m² as shown in Fig. 1. Rudder and stock material is steel with Young’s modulus 210 GPa, yield stress 235 MPa and density 7.86E-6 kg/mm³.

The stock is supported by a Thordon elastomeric bearing of type SLX assembled

on the rudder truck. It is connected to the rudder’s body by a cone coupling which is welded on the body. The stock uppermost part is clamped to a rotary valve which drives the rudder. The elastomeric bearing’s Young’s modulus is 440 MPa and its maximum working contact pressure 10~12 MPa.

The main force that strains the rudder is produced by the water flow around it. The maximum force appears at the vessel’s full speed, when the rudder turns to the maximum angle of 35 degrees. The weight and buoyancy are considerably small in relation to the water flow force; therefore they are not taken into account. To evaluate the force that is distributed to the whole surface of the rudder, a CFD analysis is performed. The results from the CFD analysis are used as boundary conditions to the structural analysis of the rudder assembly.

3. Model set-up

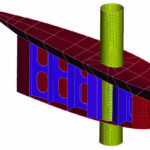

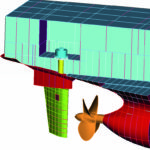

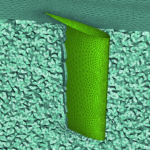

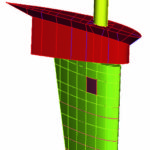

Two different FE models should be prepared for the structural and CFD analyses. Both models are created by the initial geometry; however, different representations are defined for each model. Each representation contains only the needed parts and entities for each analysis and the proper meshing parameters, quality criteria, boundary conditions, and auxiliary geometry (i.e. fluid domain). The geometrical model is shown in Fig. 2.

3.1. The CFD analysis

The first load case is a CFD analysis that will be performed in order to evaluate the pressure on the rudder body. The effect of the hull and propeller on the water flow is not taken into account for this case study and the flow is considered steady. For the definition of the CFD model, the outer skin of the rudder is isolated from the geometrical model and assembled to the computational domain which represents an open ocean area.

3.1.1. Meshing definition

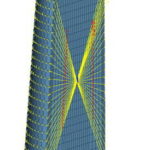

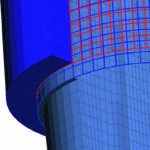

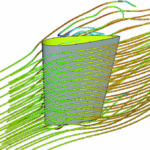

The rudder’s surface is meshed with a variable size triangular mesh. The boundary layer, generated on the rudder and the fluid surface separation, consists of five layers of prisms, generated in absolute mode with a growth factor of 1.2 and first height of 5 mm. A tetra mesh has been generated on the fluid domain with element length varying from 0.05–2 m. In the fluid domain and more specifically on the area around the rudder, a fine mesh is required to increase the result’s accuracy. In this case a special entity of Ansa, the Size Box, is defined in this area which constrains the element length of the fluid domain that resides inside the Size Box volume at 0.1 m. The final model consists of approximately 3 mill. elements (Fig. 3). The mesh is applied automatically on the model and fluid domain through the Batch Meshing Tool.

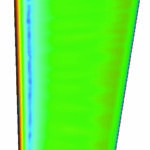

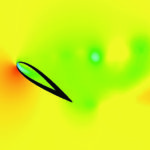

3.1.2. Results in Meta

For the CFD analysis the software Ansys Fluent version 13.0 is used. After about 1,000 iterations conversion is achieved. The static pressure is exported in Abaqus format in order to feed the static analysis that will take place later on. The results of the solution can be viewed and evaluated through ETA (version 6.7.2) which supports the read in of numerous CFD solvers results. As expected, the flow separates early on the rudder’s surface, since the angle of attack is considerably high. ETA offers many ways to view CFD results such as streamlines, vectors and contours (as shown in Figures 4 to 7) and is capable of calculating many factors and values like the Cd and Cl factors and the Yplus values.

3.2. The static analysis

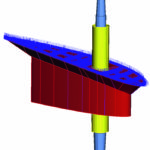

The second analysis calculates the strength of the rudder assembly and the contact pressure between the bearing and the stock. The analysis is static, non linear and it is set up for the Abaqus version 6.10. solver. The representation of the geometrical model that participates in the analysis is shown in Fig. 8.

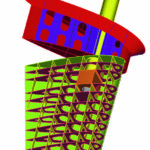

3.2.1. Meshing definition

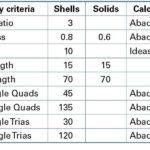

The rudder assembly is meshed with 1st order shell elements of mean element length of 50 mm. Special treatment is prescribed for holes where on these perimeters one zone of elements is applied. The quality criteria that are used are listed on Table I.

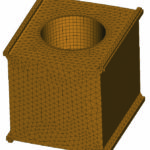

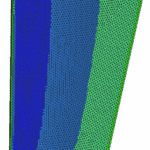

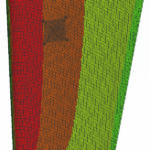

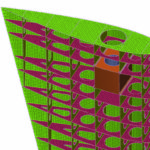

For the meshing process the Ansa Batch Meshing Tool is used. In this tool the meshing parameters and quality criteria are prescribed for a meshing scenario which is applied on the thin wall parts of the rudder and skeg. One more meshing scenario is defined for the cone coupling. In that case three layers of Pentas are created on the part’s conical surface. Above the layers, 1st order solid elements (Tetras) are prescribed for the rest of the solid part. The Batch Meshing Tool runs and applies meshing and quality improvement on all selected parts, according to the prescribed meshing scenarios without the need of any user interaction. The meshed parts are shown in Figures 9, 10, and 11.

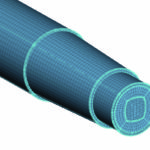

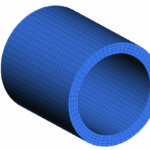

The rudder stock and the bearing are parts of great importance for this analysis, and their results need to be accurate. Thus, thin layers of Hexa elements are applied on the stock perimeter to ensure accuracy of the desired results. Additionally, the whole stock model is meshed with Hexa elements. The Hexa meshing process is a semi-automatic process in Ansa since special entities, the Hexa Boxes, are created around the stock model. Each box represents a meshing domain, in which meshing parameters such as node number, spacing and number of layers are defined. After the definition of the Hexa Boxes the mesh is created automatically. Three layers of Hexa elements are applied on the stock / bearing contact area with element length of 4.5 mm, while the rest of the part is meshed with 30 mm Hexa elements (Fig.12).

The bearing is also meshed with Hexa elements. Since its geometry is very simple there is no need to use Hexa Boxes (Fig. 13).

3.2.2. Defining boundary conditions

The structural analysis is limited to the rudder assembly, so the rest of the ship is considered rigid. Thus, boundary conditions are applied on the upper nodes of the rudder skeg which constrain the displacement and rotation in all degrees of freedom (Fig. 14). The rotary valve is also considered as rigid body. The latter constrains the displacement of the stock at all axes and the rotation of the Z axis. To represent this constraint, a Boundary entity of Abaqus is created in the center of the coupling which is connected to the stock coupling surface using rigid MPC elements (Fig. 15).

3.2.3. Automatic definition of contacts

The rudder stock is connected to the rudder by the cone coupling and supported on the rudder trunk by the elastomeric bearing. These connections are simulated by contact pair entities according to Abaqus, in order to evaluate the pressure contact during loading. A special tool of Ansa identifies the mating surfaces. Two contact pairs represent the coupling of the stock with the cone flange (Fig. 16). The type of the above pairs is defined as »tie« according to Abaqus, since no movement is expected in this area. The contact pair between the stock and the bearing is defined as »contact«, according to Abaqus, since the connection is not fixed and small sliding is allowed (Fig. 17).

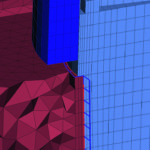

3.2.4. Mapping the CFD results

The pressure applied on the rudder’s surface, which is calculated by the CFD analysis, is considered as the loading condition for the static analysis. Therefore, pressure values for each element are exported from Fluent to a file in Abaqus format. Since the CFD analysis mesh is not compatible with the one for the static analysis, the pressure results are mapped to the static analysis mesh by regenerating equivalent pressure entities to the target elements. This is achieved with the use of the Ansa Results Mapper, which is able to import results of any type from numerous solvers (Fig. 18).

To complete the FE model that will be exported to Abaqus, the proper materials, shell and solid properties and header are defined. Output requests are defined for strain, stress and contact pressure.

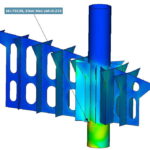

4. The optimization problem

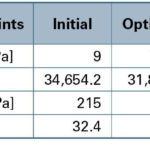

An initial run of the FE model reveals the parts and areas where maximum stress and pressure appear. The ETA post-processor is used to identify the critical areas and create reports and statistics for all parts. As shown in the following figures the maximum value for the von Mises stress occurs on the rudder trunk near to the supporting webs. The value 215 MPa which is close to the yield stress makes the increase of the truck’s thickness essential. Contact pressure results are read in ETA for the bearing-stock coupling. As shown in Fig. 20 the maximum pressure is close to the bearing’s lower edge. The maximum pressure value is 9 MPa which is acceptable. However, more uniform pressure distribution is desired. Furthermore, the deflection of the rudder is measured at the lower nodes of the model which is 32.4 mm.

In this case study the model’s behavior can be improved by modifying certain parameters that correspond to the model’s shape and shell thickness. The target of the optimization is to minimize the contact pressure on the bearing and the deflection of the rudder body. The maximum stress and the total rudder mass should be kept within an acceptable range.

4.1. Defining Morphing Parameters

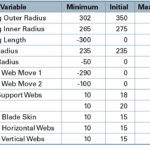

The shaping of the FE model is achieved by the Ansa Morphing Tool. Special entities, the Morphing Boxes, are created around the area of the model to be modified. As the shape of the Morphing Boxes can be modified, the relative model follows the modification. Since shaping should be performed parametrically during the optimization process, Morphing Parameters are defined and connected to the design variables of the optimization problem (Table II).

For the modification of the stock Cylindrical Morphing Boxes are used and the relative Morphing Parameters are defined which control the stock diameter as shown in Fig. 23. Two groups of Hexahedral Morphing Boxes and relative Morphing Parameters are defined to control the position of the rudder’s vertical webs (Fig. 24). The webs slide along the rudder’s outer skin without affecting its shape. Since the elements of the horizontal webs are squeezed during the above movement, special care should be taken to the horizontal web holes in order to avoid distortion.

A last Morphing Parameter is defined for the modification of the holes diameter on the horizontal and vertical webs.

4.2. Defining Ansa Parameters

The shell thickness of several parts of the rudder assembly is set as design variables. These are the parts of the vertical and horizontal webs, the trunk, the trunk supporting webs and the rudder skin. The shell thickness values are extracted to design variables through the Ansa Parameters which can control parametrically any entity of the FE model.

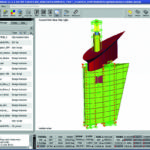

4.3. Setting up the Optimization Task

The Optimization Task is a powerful Ansa Tool, which facilitates the set-up of an optimization problem (Fig. 25). Here, the engineer can define the sequence of every action that will be executed in each optimization loop. The design variables and their properties and bounds are defined in this Task and connected with the defined Morphing and Ansa Parameters. Furthermore, complicated actions like the mesh improvement or reporting can be defined here using the Ansa scripting language.

In this case study three actions are added to the Optimization Task to ensure the model’s validity. A scripting command is added after the morphing sequence which identifies areas of poor quality elements and regenerates the mesh. A second script-

ing command checks for penetration among the parts which may occur after thickness changes. Finally, one more scripting command calculates the model’s mass and exports it to be used as objective parameter of the optimization problem.

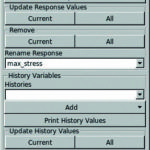

4.4. Extracting responses from Meta

The objective parameters and constraints of the optimization problem are extracted from the results of the structural simulation. To achieve this, a baseline run of the static analysis is performed and the results are read in ETA. Through the Annotation Tool of ETA, the maximum value of the contact pressure on the bearing and the maximum stress and deflection on the rudder assembly are identified. The Optimizer Setup Tool of ETA is used to export the identified values into an ASCII file of a special format ( Fig. 26). The file is read from ModeFrontier and the values are set as responses. The above sequence is recorded automatically in a session file in order to be reproduced in every optimization loop.

4.5. Coupling Ansa/Meta to ModeFrontier

For this optimization problem the ModeFrontier version 4.4.1 is used which provides dedicated »nodes« for Ansa and ETA. As the Ansa node is defined, the input variables are automatically defined corresponding to the Design Variables that have been set previously. The ETA »node« reproduces the ETA sequence of extracting responses and feeds the constraints and objective parameters. In this case study the maximum contact pressure of bearing surface and rudder assembly mass are set as objective parameters while the maximum stress and deflection are set as constraints (Fig. 27).

5. Performing optimization

For the optimization process the Multi-objective Genetic Algorithm (Moga II) is selected and the process runs for 360 iterations. The iterations are shown in the contact pressure vs. mass diagram (Fig. 28). The Pareto Frontier appears which shows the best solutions for this case study. The optimum solution reduces contact pressure and mass while the maximum stress and the displacement are kept below the acceptable values (Table III).

6. Conclusion

In this case study a spade rudder was subjected to a design optimization process in order to improve its strength and behavior. The results of the analysis led to significant changes to its shape and shell thickness. The optimization process is defined using several analyses and programs. Furthermore, many actions are needed to setup the FE models. Thus, the use of tools that automate the simulation process and facilitate the analysis set-up turns to be a matter of great importance.

Ansa and ETA pre- and post-processors have been used successfully for the definition of CFD and structural analysis. The use of sophisticated tools like Batch Meshing, Results Mapper and Contact Wizard of Ansa facilitates and automates the definition of an FE model. Furthermore, the Morphing Tool and the optimization set-up functionality of Ansa and ETA offers the engineer a helpful tool for parameterization and optimization.

Authors:

George Korbetis

Dimitris Georgoulas

Beta CAE Systems S.A., Thessaloniki/Greece

Ansa@beta-cae.gr

George Korbetis, Dimitris Georgoulas