Time is limited and technical solutions for LNG as fuel for commercial shipping are available. But neither reflect the orders of the maritime economy nor the present legal development the reality. A report by Hans-Jürgen Reuß

At the end of last year the Government of the Federal Republic of Germany set the course to make liquefied[ds_preview] natural gas (LNG) as fuel for commercial shipping more attractive by exempting it from tax. Cui bono, one may ask, because international and national legislation to bunker and to use liquefied gases on board ship as fuel for internal combustion engines will still take years (refer to HANSA 1/2013, pp. 54ff). Norway is a good example of what can be done, but up to now an exception.

The advantages of using natural gas as fuel are well-known but one should not set the hopes to high. The CO2 emission is direct proportional to the power needed, independent from the kind of fuel. Thus, for this emission the overall efficiency of the ship is more important than the question of the fuel. Compared to all other emissions natural gas has a great advantage. But to talk about »zero emission«, as even very competent institutions do, is nonsense. It is absolutely impossible to build and operate ships without any unwanted emission.

To install the necessary infrastructure to import and bunker LNG in the ports takes a long time. Thus, the large ports ordered or finished already feasibility and market studies to find out which solution suits best. One of the latest orders is the commissioning of Det Norske Veritas to develop operational procedures for LNG bunkering in Antwerp. The port authority wants to support clean shipping in the region and to position itself among the leaders in the Hamburg–Le Havre region. In this context another activity of DNV is of great interest. The classification society offers shipowners their support to make existing vessels and newbuildings »ready for LNG«. This comprises class-approved design for later simple retrofit of the LNG equipment.

The main players of the gas engine market

At the top of the marine engine market there are only two companies. With their licensees they dominate also the worldwide business of gas diesel engines, better known as dual-fuel engines. Up to now both can offer four-stroke engines working either in diesel or in Otto mode with pilot oil injection. Two-stroke dual-fuel engines can so far only be offered by MAN Diesel & Turbo.

Here is a quick look on both engine programmes. On the occasion of SMM 2012 MAN improved the programme by introducing the new engine series 35/44 DF (refer to HANSA 12/2012, pp. 18ff). With now two series of four-stroke engines it ranges from 3,060 to 18,000 kW. All two-stroke engines are available with the same output, either as diesel or as gas engines within the power range from 2,175 to 87,330 kW. MAN programme still lacks a four-stroke gas engine series at the lower end as they are needed for driving onboard generating sets. In the meantime MAN has included in its gas engine programme also a gas Otto engine, operating with a pre-chamber lean-burn system and spark ignition. For the time being the 35/44 G V-type engine is offered in a 20-cylinder version with an output of 10,600 kW, mainly for power generation plants and combined heat and power solutions.

Wärtsilä is offering an unchanged engine programme of four-stroke gas engines with a power range from 1,056 to 17,550 kW. Even not covering the upper power range the company claims for »leadership in gas technology«. The background: The company has delivered up to now more than 2,000 gas engines and collected with them more than 7 mill. running hours in both land-based and marine applications. This proud result doesn’t change much because there is still a missing link in the chain between the pressure of environmental protection and the available technology: the legal pre-conditions for global application of LNG in shipping. Wärtsilä underlines that the pure gas as well as the dual-fuel technology can be used on all types of vessels.

The development of dual-fuel engines was started by Wärtsilä in 1987 with different solutions. The breakthrough in 1995 was based on the dual-fuel technology of four-stroke engines. Only in 2010 the company launched the development of two-stroke gas engines. The present status is: »The resulting tests … demonstrated that, for the first time ever, low-speed engine performance can fully comply with IMO Tier III nitrogen oxide (NOx) limits when operating on gas.« It is intended to release the two-stroke dual-fuel engines still during the current year. They shall be available »for commercial use in 2014« and will be »incorporated into the full portfolio of engine types during 2015/2016«.

Even if most orders for dual-fuel engines reach Wärtsilä from Northern European owners the company is very active in North America, too. The latest orders from that part of the world cover, amongst others, a Canadian ferry for the St. Lawrence River and an offshore support vessel for the Mexican Gulf. Most important for Wärtsilä is the certification of the complete 34 DF engine series (2,700 to 7,200 kW) by the United States Environmental Protection Agency (EPA). The expectations of the company are high: »It will enable Wärtsilä to strongly enter the American market with marine engine technology that offers … the option of using either diesel or gas as fuel.« The above-mentioned OSV will receive the first engines and four sister vessels will follow.

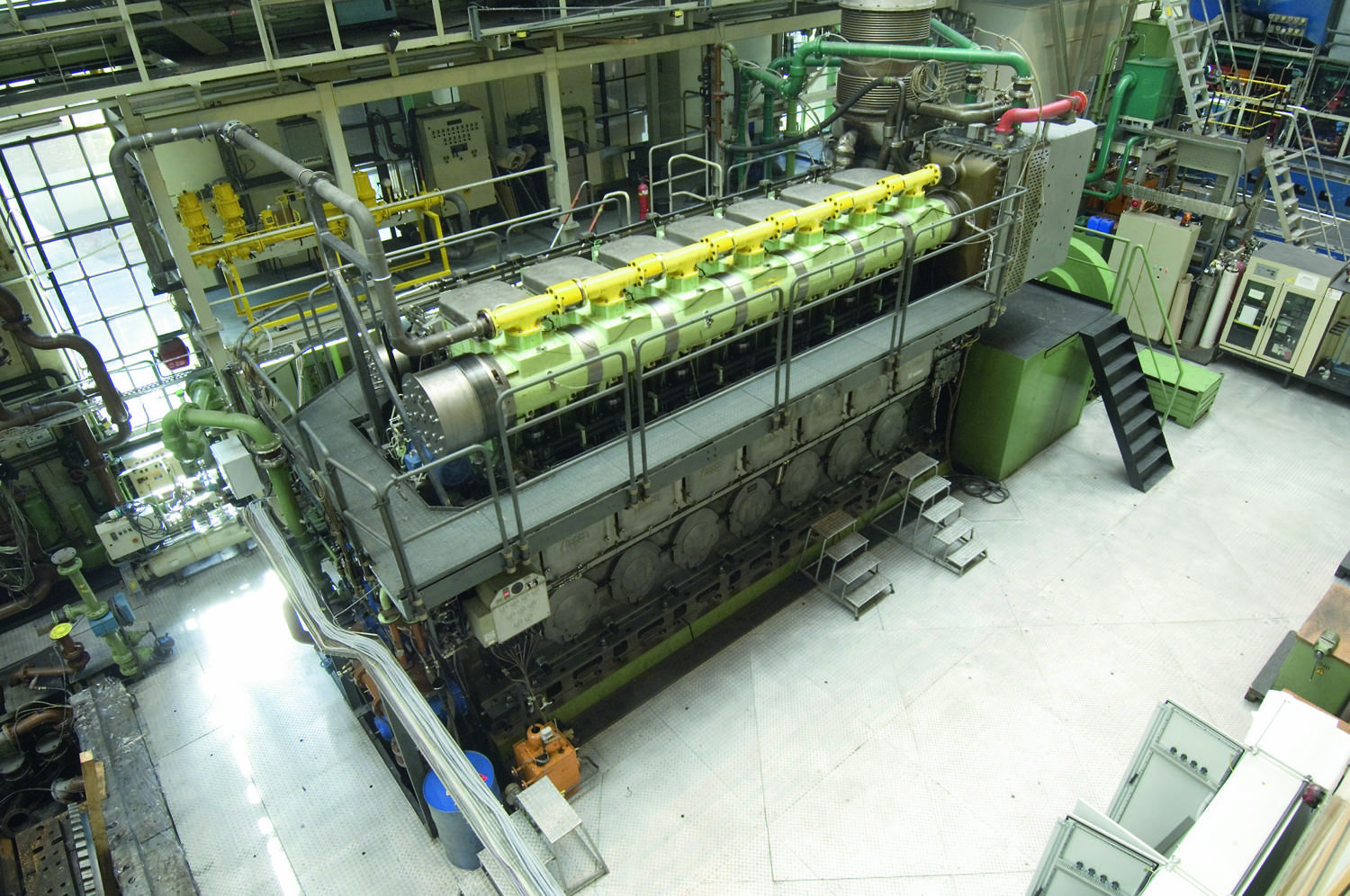

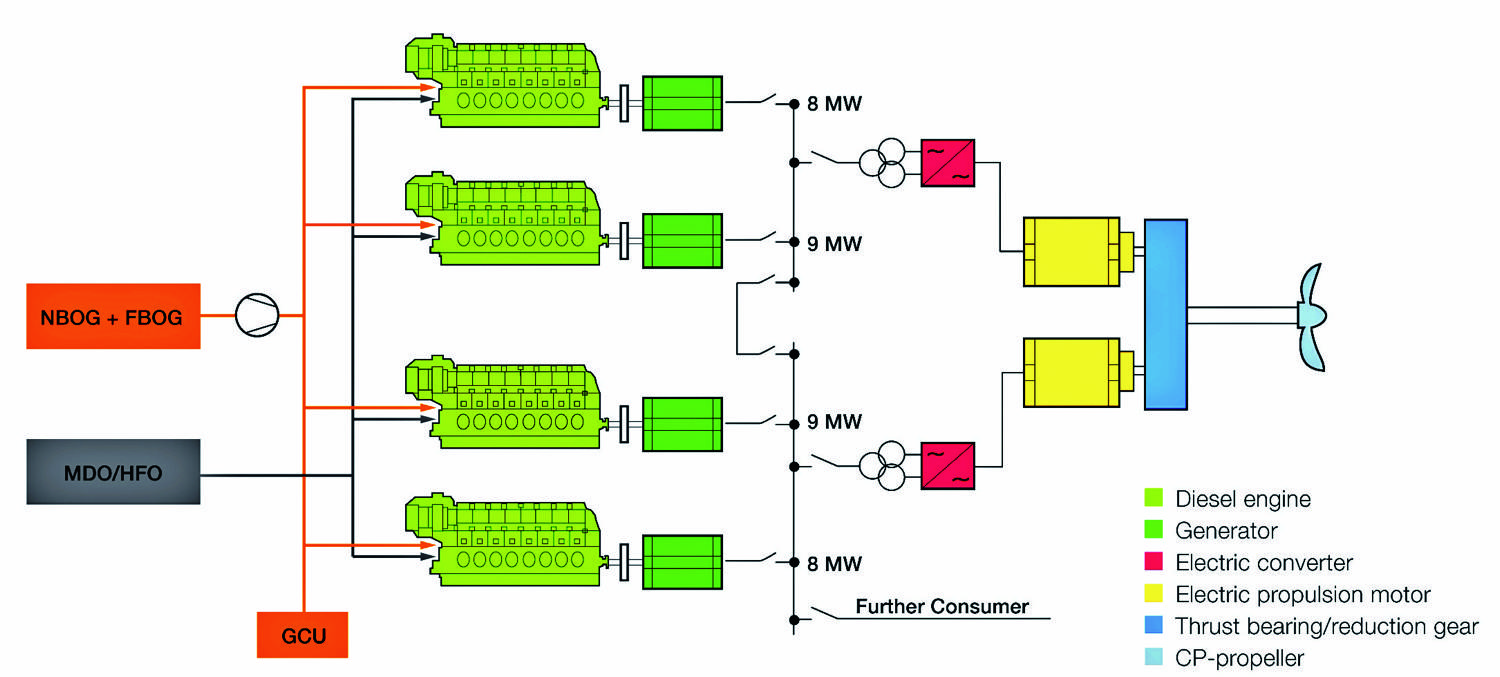

At the end of last year MAN Diesel & Turbo released the information that the company received the order for »the first LNGC newbuild globally with fuel-sharing capability«. As reported long ago, the dual-fuel engines by MAN can simultaneously burn gaseous and liquid fuels in a certain relationship. The order covers all engines for two 160,000 m3 LNG carriers (LNGC) to be built by STX Offshore & Shipping in South Korea. It comprises two eight- and two nine-cylinder engines of the 51/60 DF series with a total output of 34 MW for each vessel. The propulsion system is diesel/gas-electric. MAN received as well an option for further vessels.

Another milestone for the MAN gas engine business is the first order for two-stroke dual-fuel engines. The American shipping company TOTE has ordered the first ME-GI engines for the newbuildings of two container vessels and placed an option for three more vessels. The 3,100 TEU vessels for domestic services between Florida and Puerto Rico will be powered by eight-cylinder engines of the 70 ME-GI-C 8.2 series with a MCR of 25,191 kW at a speed of 104 min-1.

Nothing was released so far concerning the auxiliary engines but three dual-fuel medium-speed engines.

Hans-Jürgen Reuß