The construction of the second lock in Waasland Port – the dock complex

on the left bank of the Scheldt in the Port of Antwerp – is a huge project.

The new lock is set to be the largest one in the world. The construction works are now halfway. A project description

The consortium Waaslandsluis, which consists of Jan De Nul, CEI-De Meyer, Betonac, Herbosch-Kiere and Antwerp Construction, executes the[ds_preview] construction of the lock. The work comprises five major components: preparatory work, the construction of the lock itself, the construction of buildings, installation of access channels, and installation of associated access roads and railways. It is one of the key projects of the Flemish government in Belgium.

Access to the left bank of the Scheldt

Waasland Port is already accessible via a lock: the Kallo Lock. However, this has been in operation since 1979 and no longer caters for present-day needs. As a result of the steady growth in the level of activities at Waasland Port – including highly frequented roll-on/roll-off terminals and investments in new tank terminals – the Kallo Lock is reaching the limits of its capacity. A second lock on the left bank of the Scheldt also offers the Port of Antwerp reliability when the Kallo Lock is not accessible for maritime traffic. Maintenance of repair work will not create any problems as vessels may enter and leave Waasland Port via the second lock. Hence the Port of Antwerp is always sure that the docks on the left bank of the Scheldt are effectively accessible. On the right bank there are no fewer than six locks, whereas the left bank now boasts only one. The new lock will be larger than the present one and will allow for the maximum utilization of Waasland Port. The new lock is not only wider and longer than the current lock, but also deeper. So it will provide access to the docks at the Port of Antwerp on the left bank of the Scheldt for the largest ships existing at this moment.

Tidal river

The Scheldt is a tidal river. The water level has high and low tides just like the sea, whereas the water level in the port docks – behind the locks – is always the same, so that the water level between the Scheldt and the port docks is generally different but the locks enable vessels to overcome the difference in height.

Before a vessel can enter the lock the water level has to be brought to the same level as the Scheldt. This is achieved by opening and closing fixed wheel valves, huge valves in the culverts by which the lock is connected to the docks/Scheldt according to the communicating vessels principle. In order to allow the water out of the lock basin the fixed wheel valves in the culverts are opened so that the surplus water in the lock goes into the Scheldt and the water level in the lock and the river is equalized.

When the lock gate to the Scheldt is then opened, the vessel can enter the lock, whereupon the lock gate to the Scheldt is closed again and the vessel remains in the lock basin.

The same thing then occurs on the other side. The fixed wheel valves are opened on the dock side and dock water enters the lock via the culverts. The water fills the lock basin to the same level as in the docks. The lock gate on the side of the docks is then opened. The vessel may now enter the docks. While the lock is being operated, the bridges on both sides of the lock are also operated. Every time a vessel passes to enter or leave the lock and the lock gate is open, the bridge is opened, whereupon the other lock head is closed so the bridge there remains closed and the road traffic in the port can continue to circulate at all times.

Largest lock in the world

With 500m in length, the second lock in Waasland Port is as long as 28 articulated buses laid bumper to bumper. Being 68m wide, the width of the lock is comparable to a 19-lane motorway. 20,000t of structural steel was required to build the lock, the bridges and accessories. This is nearly three times more than the steel used to build the Eiffel Tower (7,300t). Also over 740,000 m³ concrete and 50,000t of reinforcement steel will be used to construct the lock.

The significance of the new lock goes beyond the port of Antwerp, as it will be an important link in the new European core transport network. The maritime sector in turn is important for the development of the Trans-European Transport Networks (TEN-T) in promoting sustainable transport, job creation, economic growth and cohesion within the European Union. Thanks to the new lock, the port of Antwerp will once more have a suitable response to the increased dimensions of modern ships, thus maintaining and further strengthening its position within Europe. The Deurganckdok lock is specifically dimensioned to take the very largest ships.

Notwithstanding the lock’s huge dimensions, the construction process calls for delicate manoeuvring. For example, the lock gates have to have a perfect seal, while the mechanism for the opening of the bridges is precision work, as the rail track obviously has to connect perfectly to and besides the bridge every time it opens and closes again. The second lock in Waasland Port will have rolling or sliding gates travelling back and forth over rails during the opening and closing.

Berendrecht lock

The second lock for Waasland Port is a sea lock akin to the Berendrecht Lock. This lock on the northern part of the Port of Antwerp and on the right bank of the Scheldt is currently the largest shipping lock in the world, being 500m long, 68m wide and 13.58m deep. It serves as a model for the Deurganckdok lock.

The lock comprises a lock chamber – where the vessels are stationed to be transferred – and two rolling gates at each end. Although only one gate is closed on each side when the lock is being used, the second gate ensures reliability during maintenance and repair work at the gates. The gates roll – supported on a special bottom-rolling platform – back and forth on bottom rails and are also supported by top rails and an upper support wagon in the gate chamber. The gates are moved by electrically powered cables.

Challenging construction

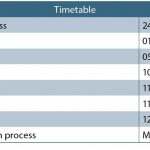

The project is to be fully completed within 53 months. To realize this, enormous amounts of work have to be executed each day. After some preparation works the building of the lock was started with the creation of a watertight screen around the construction site. This watertight screen was realized by a cement bentonite slurry wall and had to make it possible to install a drainage installation without influence for the neighborhood. A total of 90,000m² of screen was made by four excavation machines, working 16 hours a day during five months. After the realization of this wall the drainage installation could be installed and the excavation works could start.

A total of 4,500,000m³ of soil had to be excavated within one year. Each day an average of 20,000m³ was moved by two big excavators and 20 dump trucks. After the excavation of the trench, the concrete works could start. In about 24 months, 740,000m³ of concrete have to be poured. This means an average of 1,500m³ each day. To make this possible the concrete is fabricated in two batching plants with a total capacity of 240m³/h, installed on the construction site of the locks. Also 55,000t of reinforcement steel is to be placed.

After completion of the concrete works, the installation of the lock doors and the bridges will be done. All this makes it possible to finish the works in March 2016. By then the lock will be operational and the first ships can enter the Waasland harbor by the new lock.

Eric Beyts