The Switch plans to grow its marine business by 200 % in the next five years. That builds on many recent orders, the acquisition of Wärtsilä drives and the situation of its parent company Yaskawa Electric Corporation.

The Finnish headquartered company, focused on the development [ds_preview]and supply of advanced drive train solutions, believes its permanent magnet (PM) and frequency converter technology can have the same transformational effect on marine as it has had in wind. In wind, The Switch is an industry supplier, providing permanent magnet generators and full-power converters to wind turbines worldwide. According to the company in total, the firm boasts an installed capacity in excess of 13 GW. The largest low voltage (690 V) PM generators installed have a capacity of 8.6 MW.

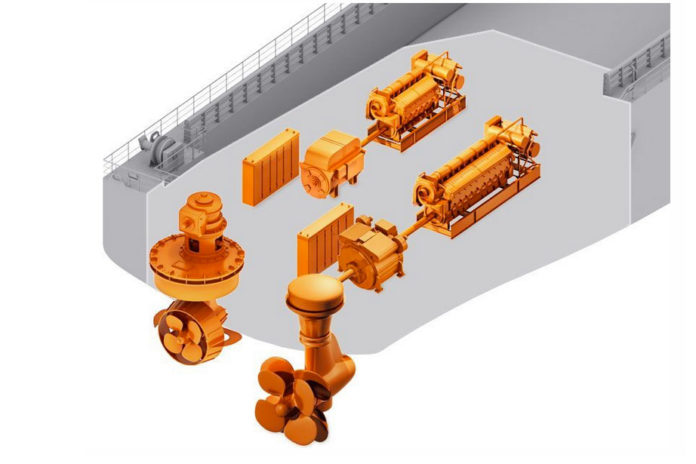

The Switch manufactures PM machines that, in conjunction with frequency converters, convert mechanical energy into electric power that can then be utilized for onboard systems and equipment. With modular, flexible and lightweight designs, the solutions drive a new wave of efficiency.

Its PM shaft generators can be used to create cost-effective electricity and save fuel – with large merchant vessels potentially consuming 50 % less energy during slow steaming. Meanwhile, vessels utilizing electric propulsion can optimize fuel consumption and access predictable and flexible power with unmatched power density.

In addition, The Switch’s frequency converters deliver reliable and accurate speed control. This makes them ideal for vessels operating in varying environments and speed ranges – such as ferries, cruise ships, ice breakers and tugs – and perfectly suited to the demands of dynamic positioning systems.

Despite entering the segment in 2013, The Switch has received over 20 orders for its PM shaft generator technology, with a growing number of enquiries. Its latest agreements, to be delivered by solutions provider WE Tech, cover PM shaft generators for two Toll Shipping 12,000 dwt RoRo vessels and a series of four Stena RoRo RoPax ferries. All of them are being built in China, with Toll’s constructed at Jinling Shipyard and Stena’s at AVIC Weihai Shipyard. Deliveries span from late 2017 through to January 2018.