U.S.-based maritime supplier Thordon Bearings and Dubais shipyard Drydocks World aim to cooperate for a better distribution of seawater lubricated bearing systems.

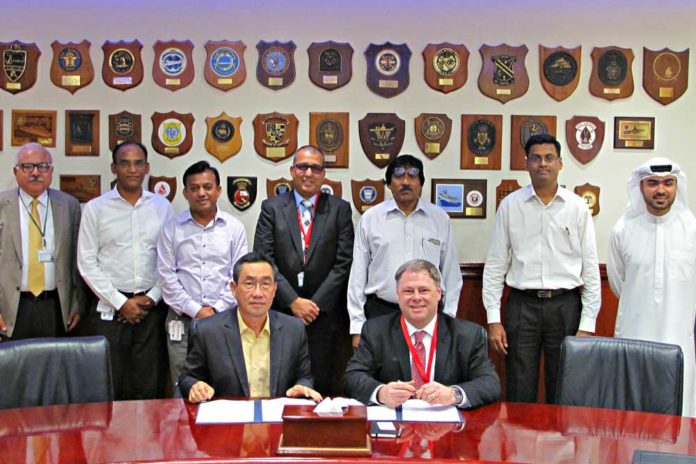

Thordon Bearings CEO Terry McGowan and DDW‘s COO Mohammad Rizal today have signed an agreement under which they inte[ds_preview]nd to promote the conversion of ships’ oil lubricated propeller shafts to Thordon’s »Compac« open seawater lubricated bearing system.

The agreement will create an action plan in which a specialist team, comprised of Drydocks World-Dubai and Thordon Bearings’ personnel, offer support to ship managers and owners looking to ensure their vessels are fully compliant with environmental legislation prohibiting the discharge of oil from the oil-to-sea interface of ships‘ propeller shafts.

Rizal said: »By entering into this partnership, we will not only have an opportunity to expand our service offering, but will also have the opportunity to provide our customers with a real, long-term solution to the environmental problems they face with oil lubricated stern tube bearings and seals. With concerns increasingly being raised about the impact oil discharges have on the marine environment, converting an oil lubricated system to seawater is the only guaranteed solution for today and tomorrow.«

Leaking shaft seals are known to be a significant contributor to on-going pollution at sea. The partners said, the use of biodegradable lubricants, which are an improvement over mineral oils, are still a very expensive option for shipowners and some are having seal compatibility issues. »Even biodegradable lubricants still need to be reported to authorities when discharges occur. Thordon provides a solution that uses seawater as the lubricant that meets all regulations, eliminating any risk of oil pollution«, it was added.

McGowan explained, »there are fewer components, fewer pipe-runs and no air equipment is required with a seawater lubricated system. Plus, with recent class society rule changes, seawater lubricated propeller shaft bearing systems no longer have a pre-determined shaft withdrawals as long as certain monitoring conditions are met.«