While various manufacturers of ballast water treatment systems are reporting large orders, industry organisations are calling on shipping companies to take action as quickly as possible. One thing is clear: shipping has become more active in this area. By Michael Meyer

Very recently, shipping organization Bimco released an advisory that the industry must act now to plan for ballast water compliance[ds_preview]. »With the industry’s eyes firmly fixed on the 2020 sulphur cap, shipowners might be paying less attention to installing a ballast water management system.

But time will run out to comply with the ballast water regulation and delaying to the last minute could be costly,« it was said. Up until recently, it was widely accepted that ships exchanged ballast water mid sea to avoid discharging water potentially containing invasive aquatic species close to shore. This practice will soon be insufficient in terms of compliance.

Ashok Srinivasan, Manager for Maritime Technology and Regulation at Bimco stated: »We strongly advise to get the installation planned as soon as possible. The compliance window is meant to spread out installations around the world, and if the majority of shipowners wait until the last minute, as close to 2024 as possible, there will be bottlenecks.«

The International Maritime Organization’s Ballast Water Convention came into force on 8 September 2017, while the United States Coast Guard (USCG) regulations have been in force since 2012. However, after a lot of discussions and complaints by the shipping industry – and because the technical products were not in place in a sufficient manner – owners were given more time (HANSA 07/2018). For vessels operating in US waters, this date now is generally 1 January 2021, although extensions are still possible. It is important to remember, that there are even stricter rules of the U.S. Coast Guard to be compliant with than the ones from IMO.

For other regions, the compliance deadline is 8 September 2024. Depending on the International Oil Pollution Prevention certificate renewal – which should be done every five years –, this could be even earlier. »September 2024 seems far away, but from this date onwards, ships must have a ballast water management system installed, certified and ready to use, or use other methods of compliance to comply with the discharge standard.

Penalties may apply for non-compliance,« Bimco says. Srinivasan added: »Few players in the industry have installed the ballast water management systems so far. Not only might the industry face bottlenecks if there is a last-minute rush to the yards or retrofitting locations, but it may also be much more expensive, as a sharp rise in demand could drive prices up.« Some 40,000 to 60,000 vessels need to be equipped.

Both the IMO Ballast Water Convention and the United States Coast Guard (USCG) regulations aim to prevent contamination of local waters with aquatic species by stopping ships from discharging ballast water containing unwanted invasive organisms and species. Some analysts argue that each day around 7,000 marine species hide away in ballast water tanks and that every year about 10 bn t of ballast water are transported arond the globe. The available ballast water management systems use a range of technologies, including UV filtration, chemical injection, chlorination etc.

Maritime insurance company Gard recomended shipowners already to carry out a detailled feasibility study for each vessel in their fleets to evaluate the suitability of available ballast water treatment system solutions. »Consider the time factor,« it was added, because availability and delivery times for approved treatment systems will vary depending on demand, as will shipyard capacity.

Many shipowners have opted to conduct the IOPP survey ahead of time to postpone the installation of a ballast water treatment system and accordingly, there may be future time periods, such as the year 2022, that will be particularly busy for suppliers, yards and classification societies. Once a ballast water treatment system solution has been selected, officers and crew must be properly trained and be competent to carry out their assigned ballast water management duties and functions. According to Gard, procedures for training and familiarisation with the BWM Convention should be incorporated in the company’s safety management system (SMS).

In September 2018 already Japanese classification society ClassNK announced its recommendation to install as early as possible. In its own fleet of 7,315 ships which are obligated to install BMWS, only 1,915 ships had completed the installation by the end of August.

On the product side, there has been some movement recently. Classification society American Bureau of Shipping (ABS), with quite a lot of knowledge about the U.S market, revealed at the end of 2018 that now 13 systems received approval from the United States Coast Guard.

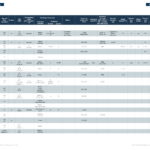

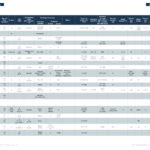

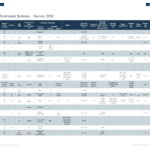

(HANSA presents a comprehensive list of manufacturers, products and approvals on the following pages of this issue.)

Issues? Yes, but …

In a recently released survey, ABS found that just over a third of installed management systems to be fully operational. The survey integrated feedback from more than 60 shipowners and almost 500 ships – including seven main types of systems supplied by 22 different vendors.

In general, about one third of the participants claimed to be happy with the reliabilty. However, this implicates that this aspect remains a concern for a big share of ship owners.

Two thirds of the respondents saw their installed system inoperable (6%) or operationally problematic (59%). Several said, that more crew training was neccessary. On a financial argument, just 22% of respondents said they were happy with the OPEX they were experiencing, suggesting it was above the estimates provided by the manufacturers.

Global survey of existing BWTS: Chosen technologies included

• Filtration + Side-stream EC + Neutralization (29%)

• Filtration + UV Treatment (20.7%)

• Ozone Treatment + Neutralization (19.9%)

• Filtration + Full Flow (In-line) EC + Neutralization (17.8%)

• Full Flow (In-line) EC (7.5%)

• Filtration + Chlorination via chemical addition (5%)

• Filtration + Deoxygenation (0.2%)

The Ballastwater Equipment Manufacturers’ Association (BEMA) – formed in April, 2018 signed up nearly forty members last year. »With that voice, we want to speak to you today to remind each of you that the compliance dates are rapidly approaching«, BEMA president Mark Riggio emphasized.

The last possible minute

Talking virtually to all shipowners, Riggio emphasized: »Have there been issues with the early designs of Ballast Water Management Systems? Absolutely. Can a Ballast Water Management System be difficult to operate? Yes. Will a Ballast Water Management System affect the normal, pre-ballast water treatment operations of your vessels? Definitely. All of these questions have led many of you to delay this decision until the last possible minute in order to optimize your best chance for success. While we understand that thought process, we want to caution you that it is already the last possible minute.«

Michael Meyer