Regulatory pressure is pushing large combustion engine makers to clean up their act. Paolo Tonon, Vice President Communication at the International Council on Combustion Engines (CIMAC), sees this as a challenge and incentive rather than a reason to worry

CIMAC has recently been making a strong case for the Power-to-X concept and cross industry cooperation needed[ds_preview] to make it become a reality. That’s the future – what’s moving the industry right now?

Paolo Tonon: A great deal of discussion centres around the Sulphur Cap 2020 and the overall effect of the shifting focus in engine emissions emphasis on Greenhouse Gases (GHG). As a result, the large engine industry is working simultaneously on the full spectrum of engine emissions. However, it must be said that because of the correlation between carbon dioxide (CO2) to fuel consumption, GHG reduction is essentially an increased focus on a perennial concern of every single engine developer and operator.

What will be discussed at this year’s CIMAC World Congress – besides Power-to-X and cross-sector cooperation?

Tonon: CIMAC acted presciently when it founded the new working group System Integration. We think a lot of the discussion will centre around not only on the necessary interactions among systems onboard ships but among all the engine industry stakeholders: propulsion system builders, ship designers, and ship operators. Because one thing is certain – the CO2 targets set for 2050 will not be met by engine development alone. In the past, engines were singled out as the only source of emissions on a ship, even though inefficiencies elsewhere were also having a negative impact on emissions. Now the approach is a more holistic one, with other factors being considered, i.e. the overall efficiency of the system we call a ship.

In a time of huge industry change, CIMAC aims to close the gap between ship-owners, ship-operators, and the shipping industry. This is reflected in an increased space given to end-users round tables.

At the moment, zero emission operation still seems to be far away. What are the concrete measures and development areas right now?

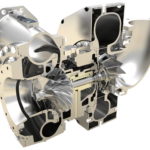

Tonon: There is still immense potential in the traditional areas of engine development – fuel injection, turbocharging and engine control. Fuel injection pressures which continue to rise is helping to increase engine efficiency of both two- and four-stroke engines as well as with the advancement of the two-stage turbocharging on four-stroke only beginning to be leveraged.

In terms of control, electronics continue to become more sophisticated. The initial results of variable valve timing on large four-strokes engines are showing great potential in terms of improved overall control and making the engines far more flexible and economical.

On the two-stroke side, there are innovative turbocharging and control systems, such as the first sequential turbochargers on two-strokes. New flexible exhaust valve timing and advanced turbochargers allow ships to switch from slow steaming to commercial cruising speeds easily and without any major modifications. This allows ship operators to closely match their power to their actual load profile.

What could be effective short term solutions in the fight against green house gases?

Tonon: A great hope for reducing both GHG and noxious emissions in the short term is gas- and dual-fuel engines. Since the last Congress two-stroke dual-fuel engines with both high- and low-pressure gas injection have proliferated while four-stroke dual-fuel engines are establishing themselves in all types of vessel, not only LNG carriers.

This change is driven by IMO Tier III NOx limits and the Sulphur Cap 2020. LNG being sulphur free is also helping the fight against GHG. Dual-fuel engines burning methane (the main constituent of LNG) produce less CO2 per kWh than engines burning liquid fuels. This is because methane (CH4) has the lowest ratio of carbon to hydrogen of hydrocarbon fuels. The methane slip is of course something we need to consider, and we are supporting researching activities here accordingly.

Finally, engine component and engine consumable manufacturers are constantly working to reduce friction as a means of raising engine efficiency. Remote monitoring, control, and diagnostics are also starting to benefit fuel consumption and helping the shipping industry become more efficient as a whole.

Do conventional diesel engines still play a role on the market or is dual fuel already the new standard solution?

Tonon: I do not see a full renunciation of diesel engines. Applications for dual-fuel engines are certainly growing, especially in short-sea applications like container feeders, ferries and offshore vessels. The likely scenario for ocean-going vessels in the foreseeable future will be dual-fuel engines in NOx and sulphur Emission Control Areas (ECA), while reverting to diesel engines on the high seas.

A new-built vessel without batteries on board for peak shaving or emission free port operation – will this be even possible in a few years from now?

Tonon: Certainly, we are going to see many ships with electric and hybrid propulsion systems featuring batteries and fuel cells. There are already many pilot projects and commercial diesel-electric and hybrid applications for vessels with more than one operating mode. This includes ferries that dock and manoeuvre frequently and tugs that can operate on batteries when moving between tows. There are also offshore vessels that can switch to electric power when cruising to and from oilrigs and production platforms but use their combustion engines, continuously or intermittently, when handling anchors or fully loaded.

At the other extreme, based on the current state-of-the-art, there is a limited scope for battery or fuel cell power on ocean-going ships. Neither power sources can achieve the power density or power-to weight and power-to-space ratios typical of combustion engine propulsion. Fitting these large ships with batteries or fuel cells only for use in ECAs or harbours would rob them of a great deal of payload.

How do you estimate the market potential for bio fuels – a big opportunity for conventional engine technology?

Tonon: Low emission sustainable fuels will be the key to the internal combustion engine maintaining its position as the shipping industry’s prime mover of choice. However, a limiting factor with bio-fuels is the availability of agricultural land, especially when global population growth is expected to increase at such a rapid pace. Moreover, the engine industry has already had false starts with palm oil and jatropha oil. Of the alternative fuels under discussion, the most exciting and possibly most feasible prospect is Power-to-Fuel/Gas. If climatic regions like Europe, which are already able to produce an excess of renewable wind and solar energy – think about the potential in tropical regions. These regions can have wind and solar energy plants fully dedicated solely on the production of hydrogen from electrolysis process.

With regard to new fuels and Power-to-X technology, CIMAC emphasizes the need for cross sector cooperation. Is this concept a reality already?

Tonon: The challenges are clear and substantial, essentially it is up to the engine industry to prove its case. Only by demonstrating that the strategy is viable can we ensure that the political will exists to go down the Power-to-X road and on a global scale. As stated, the engine industry is confident that its products will run on whatever new fuels emerge. The challenges are on the production side and of course, we must get the oil and gas industry onboard. There is no uncertainty in the growing commitment of the large engine industry to make Power-to-X work.

What are the challenges and developments within this big picture that worry the industry right now?

Tonon: Any and all of the above! But these matters are seen as incentives and challenges not issues or worries. By cooperating with legislators, the large engine industry has so far fulfilled all its emission commitments.

For the engine industry the war for talents is important to win. With all the new emission targets and the rise of new fuels, there is an ocean of opportunities for new talents to join this industry sector and play an important role for the future. Every development engineer wants to dedicate their career to the further development of their product. Today, as well as their personal satisfaction, engine R&D departments – in fact, all the stakeholders in the large engine industry – have not just step changes in their sights but a glittering prize: the zero-emissions propulsion is tantalisingly close!

Interview: Felix Selzer