After a joint development project (JDP) with marine insurers, classification society

DNV GL has updated its shaft alignment rules to differentiate between Environmentally Acceptable Lubricants (EAL) and mineral oils in stern tubes

The regulatory update is based on the first phase of the JDP, which was done in cooperation with The Swedish[ds_preview] Club, Norwegian Hull Club, Gard and Skuld. The intention was to test the potential influence of EALs on failures in stern tube bearings.

The JDP already entered the next stage, where oil film forming capabilities, mixed/boundary lubrication behaviour and lubricant degradation will be further scrutinized, the norwegian-german society announced during Nor-Shipping in Oslo. For now, the updated rules applying to newbuildings are effective since 1 July.

Upsurge in bearing failure

On reason to initiate the project was an upsurge in stern tube bearing failures that coincided with the increased uptake of EALs after the introduction of regulations requiring their use in commercial vessels trading in U.S. waters in late 2013. Wiping was the dominant failure mode. Failures typically occurred during sea trials, mooring trials and at partly submerged propeller operation.

In phase 1 the partners focused on mapping out differences in the load carrying capacity between the several times more expensive EALs and mineral oils. DNV GL has overseen detailed laboratory testing by Leonardo Testing Services Ltd. at the University of Sheffield, UK, and by INSAVALOR at INSA Lyon, France.

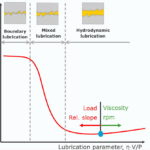

»Phase 1 has looked into how pressure, temperature and shear rate influence the viscosity of the lubricants, thereby affecting the oil film thickness and the load-carrying capacity,« says Øystein Åsheim Alnes, principal engineer at DNV GL. He adds, the test results have proven that, in particular, the pressure- and temperature viscosity properties of EALs are different to those of an equal grade mineral oil.

»The findings show that while EALs provide safety margins that are equal to mineral oils in most operating modes, there are transient conditions where the EALs can have a reduced load carrying capacity,« Alnes emphasizes.

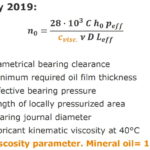

In light of the results from the JDP, the classification society has added a viscosity influence parameter to the existing lubrication rule criteria for the aft most propeller shaft bearings. The own lubrication criteria do now provide yards and designers with a »strong tool« for optimizing stern tube bearing design, including both the lubricant viscosity and now the lubricant type.

The way ahead

For vessels in operation DNV GL recommends to switch to the next higher viscosity grade if converting from mineral oil to EAL. When more research data becomes available, a search for improved ways to handle the differential between mineral oil and EAL is planned. The study is still ongoing.

While phase 1 and phase 2 are focusing on design issues (non-degraded lubricants), there are several operational challenges to EALs in stern tubes that the classification is also working on. These are amongst others accelerated wear rates of seals and bearings, hydrolysis, oxidation stability, change-over procedures and quickly rising metal content in oil samples.