2022 promises to be the hottest year in the retrofit market for Ballast Water Management Systems (BWMS). Manufacturers have prepared for that by developing easy-to-install solutions. By Felix Selzer

The technology for Ballast Water Management Systems has matured, whether owners opt for UV, electro chlorination or for other tr[ds_preview]eatment technologies. »Now, we get into the mature phase of the ballast water retrofit market,« Maxime Dedeurwaerder, Business Unit Director Bio-Sea, tells HANSA. »While some owners with strong resources can buy system components and services from different suppliers, many are interested in turnkey solutions,« he says. Besides the system itself, the French company offers design and integration along with documentation updates and certification – »the whole package«. »We do outsource some jobs, but we take the responsibility,« says Dedeurwaerder. This approach is supposed to be simpler for the client while, at the same time, it provides high quality and security and thus reduces the overall risk. But Dedeurwaerder emphasizes that it is still no-one-size-fits-all solution but tailor-made engineering.

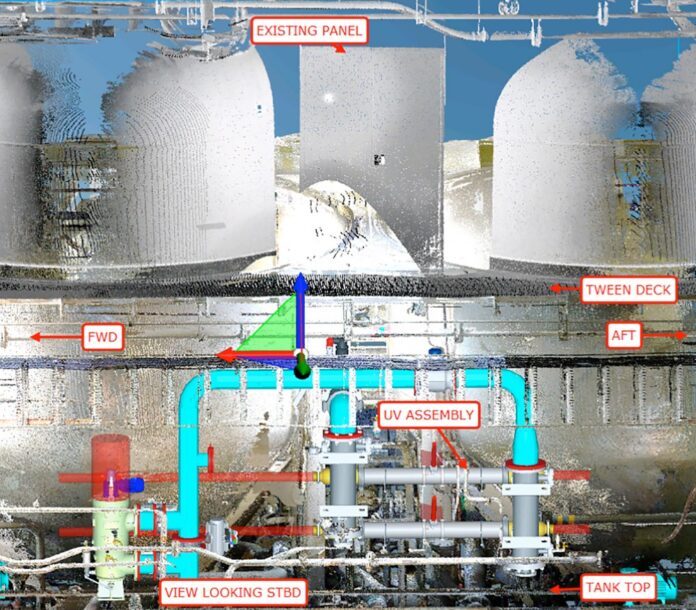

Following increased shipowner demand for turnkey BWMS retrofit solutions, the group has added 3D laser scanning and modelling to its engineering and design services. This is intended to reduce the time for installation in drydock. The digital scanning of a ship’s compartment generates a 3D image from which engineers can find the optimum site for its system and develop more detailed engineering to expedite class approvals and installation, explains Florian Cortes, Technical Director Bio-Sea, Bio-UV Group.

»We are working in a very competitive market. Since there is no return of investment of ballast water treatment systems, we have to be competitive,« adds Dedeurwaerder. The company has recently brought its M-Series system to the market, which is very compact and has low height requirements for the installation space. M-Series is a multi-lamp UV reactor designed specifically for flow rates of up to more than 2,100m3/h. The modular system is particularly interesting for vessels that need only low flow rates such as OSV, yachts, small cargo ships or research vessels.

»We are also servicing a lot of last minute needs and can supply the system in eight weeks or less,« says Dedeurwaerder. The company is located near Montpellier in France and has its production also in Europe – an advantage in times of disrupted supply chains. As a next step, in 2022 Dedeurwaerder wants to »complete the full circle« through partnerships with system integrators and installation companies.

One size fits all

Greek company Erma First is also expecting 2022 to be the busiest year for BWMS installations, Sales Director Nikos Drimalas tells HANSA. To benefit from the expected BWMS rush this year, Erma First has expanded its range of BWMS by acquiring US-based company OneTank with their »simplified« ballast water treatment technology. The OneTank system promises to have the »smallest footprint at the lowest total cost of ownership,« says Drimalas. »There is no 3D scanning necessary, it is a one-size-fits-all solution,« he adds.

The system has been developed for vessels that have limited space and power for BWMS and that are not highly depended on ballasting operations with one or few tanks. According to Erma First, it is compact, simple to use, and fully automated. It delivers a quick to install additional solution for small ballast tanks on big ships as well as a stand-alone solution for small vessels such as yachts, tugs and offshore support vessels.

OneTank treats ballast water within the vessel’s ballast tank and has no filters, ultra-violet lamps or electrolytic chlorine generators. Its footprint is only 600 mm x 600 mm, its power consumption is »similar to that of a household washing machine,« Drimalas says. With low running costs and fully regulatory compliance, OneTank is said to provide a ballast water management solution which works in all water qualities and salinities.

The system uses an 8.25 % or 12.5 % sodium hypochlorite (bleach) and 30 % sodium thiosulfate solution – readily available chemicals that can be purchased from suppliers worldwide. For smaller vessels, a 20-litre container of 12.5 % bleach will treat approximately 288 m3 of ballast water. For larger vessels, OneTank can treat tanks up to 4,000 m3.

Moreover, Erma First has teamed up with MAN Energy Solutions Benelux. Via MAN PrimeServ Omnicare, the company will be providing after-sales technical support to vessels equipped with Erma First ballast water treatment systems calling at ports and repair yards in Northern Europe. The onboard equipment services include troubleshooting, installation, maintenance, calibration and testing related issues.

More than 80% of vessels serviced under the agreement have MAN engines or turbochargers installed already, but Dimitris Kalogeropoulos, Head of Sales at MAN Energy Solutions Benelux, explains that he also aims to create spin-off business for MAN. »We are promoting partnerships with third party companies that are leaders in their areas, the customers and vessels are the same,« he says.

Capacity bottleneck worsening

BWMS maker Optimarin warns shipowners of delaying yard stays for ballast water management system retrofits as the clock ticks on installation time. As freight rates are sky-high in some market segments, many are tempted to keep their vessels trading rather than undergoing maintenance. »There is definitely a commercial rationale for carrying out retrofits in the near term rather than waiting due to the huge backlog of vessels that need to be retrofitted over the next few years to gain IMO compliance, which will be a licence to trade in the future,« says Optimarin’s chief executive Leiv Kallestad.

The Norwegian company is benefiting from a current wave of demand for BWT systems but Kallestad says the peak period for installation is moving out in time towards 2023 as owners seek to keep their ships operating as long as possible – and this may worsen a capacity bottleneck that could push up prices for equipment and retrofit work.

»No one wants to take their ship out of trading while markets are booming. At the same time, the continued presence of Covid-19, congestion in the supply chain and logistical challenges, crew changes and other operational disruption have resulted in various permit extensions of up to six months or longer,« he explains.

While this will extend the retrofit wave as it will allow more time for installation, Kallestad points out shipowners are still hopefully taking a calculated risk by deferring installations as the drydocking window tightens.

An estimated 35,000 vessels still need to have BWMS installed ahead of the September 2024 deadline for implementation of the IMO’s ballast water management convention.

Optimarin has though honed a fast-track delivery model to tackle the supply bottleneck. A BWMS retrofit is a protracted process that requires detailed planning – typically with an engineering lead time of six months before installation – and drydock capacity being secured ahead of time.

Optimarin says its still able to deliver a system within 30 days due to a streamlined documentation process and the modular flexibility of its technology. But component shortages and logistical challenges that have hit many industries may make it difficult to give delivery guarantees.

The company has scaled down and simplified the components of its BWMS through a rigorous product improvement programme, resulting in a more compact system with a smaller footprint that makes it easier to install on larger vessels, while the company provides lifecycle support through its global aftersales network. The company has also formed an alliance with UK-based Newport Shipping that enables it to offer a turnkey BWM solution with drydock availability at one of Newport’s 15 partner yards worldwide and favourable deferred payment terms.