The 14th HIPER Conference was the third such event held in COVID times. Advanced thinkers from research and industry met in Cortona, Italy, to discuss the future of shipping, with strong focus on decarbonization. By Volker Bertram[ds_preview]

The location in Tuscany was ideal: somewhere between Vinci, which gave us Leonardo and his ingenuity, and Lago Trasimeno where Hannibal defeated the Romans, relying on superior agility and tactical flexibility of smaller units. HIPER meets somewhere between the two with a unique community of maritime innovators.

Think out of the box and be more agile than the competition. First-class engineering, creative ingenuity and entrepreneurship gel at HIPER – also this year, where COVID in its third year still constrained the exchange on site in numbers, but not in quality.

This year, everything seemed to tie into decarbonization – the great Leitmotif for the industry as the 2023 implementation of CII (Carbon Intensity Indicator) and EEXI (Energy Efficiency Design Index) are looming on the horizon. Papers presented covered various aspects of the larger theme:

- New fuels, of course.

- Wind assisted ship propulsion, of course.

- Smart is green, green is smart: optimization of design and operation through smart solutions

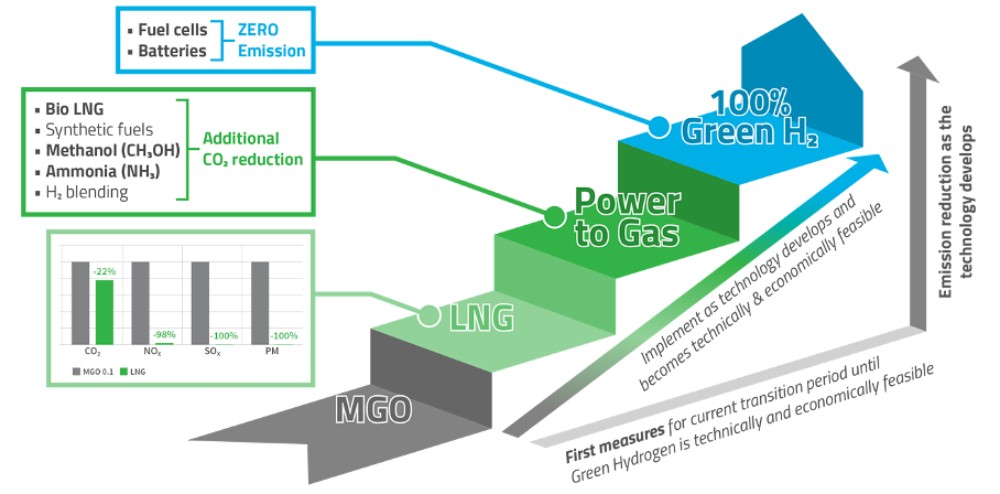

The general trends were nicely summarized by Morten Løvstad (DNV) on the decarbonizing quest for future bulk carriers, discussing likely measures from now to 2050. In the short-term to maybe 2030, the required goals will be achieved through moderate engine power limitation, requiring only negligible sacrifices on speed, and tried and proven energy saving measures, which will be implemented just more stringently and wider than in the past.

»Can we achieve 30 % energy efficiency improvement over the 2013 baseline, i.e. can we achieve the IMO targets for the EEDI, just by consequently exploiting existing, mature technology? Yes, we can,« confirms Løvstad, referring to the »Diamond 2« project for an Ultramax bulk carrier.

Beyond 2030, the industry will have to leave the comfort zone of the tried and proven and explore largely yet unknown options including alternative fuels – it may not be time yet to set sails for this Terra Incognita, but we should definitely start gathering whatever information we can and start mapping our journey into the largely unknown.

»How do we fairly compare a larger set of energy saving options, which have different costs and different saving potential, which in turn may differ over time or for different operational parameters, and all that with typically limited information and time?«

DNV did just that with shipyards in joint industry projects and came up with Ultramax and Newcastlemax design studies that combine a lot of options including wind-assisted ship propulsion and alternative fuel concepts (ammonia and methanol).

Future fuels

What is the first thing that comes to your mind when you hear »decarbonization«? For most of us, the answer is »future fuels«, specifically no-carbon fuels like ammonia or hydrogen replacing currently favoured low-carbon fuels like LNG. Not wrong, but focussing on the far horizon rather than the next steps for the majority of ships. There was wide consensus that the times are over, where one fuel would dominate the ship-ping industry, like HFO did pre-2020. The future is more complex and more diverse, and may evolve differently in different regions and for different ship type segments. Embrace diversity, also in fuels and associated machinery.

LNG is a so-called bridging technology to other gases as fuels. Current machinery technology and regulations, such as dual-fuel engines or fuel cells, are being developed and tested for LNG, which will in the medium-to-long term benefit other fuels that will play a major role in the decarbonization process, namely hydrogen and ammonia.

Lars Ravens (eCap Marine) described recent developments for clean power Solutions for the maritime world. eCap Marine, a spin-off of well-known Becker Marine, has focused in the past on clean in-port power supply from LNG delivered by barges to the ships. More recently, the engineering know-how has been applied to hydrogen packs for power generation and the conversion of small workboats and pleasure crafts to zero-emission propulsion based on hydrogen.

Where some in the industry see problems, others like the eCap entrepreneurs see opportunities: »these [fuel] alternatives to the conventional solutions [..] do not necessarily have to mean additional challenges. They also open up prospects that were previously undiscovered or not considered as being interesting,« elaborated Ravens.

A similarly optimistic note was struck by Jogchum Bruinsma (Nedstack), who presented a case study envisioning hydrogen as a fuel and fuel cells as realistic conversion option for a deep-sea dry-cargo vessel. The vision is not a pipe dream from the Netherlands but based on current R&D projects laying the foundation for a strong maritime hydrogen economy in the Netherlands, which focuses on smaller and short-term more realistic ship types important for the Dutch shipping industry: inland shipping new construction, inland shipping retrofit, coastal/shortsea shipping, passenger vessels and specialist ships. Strategic grand vision and tactical small-step implementation need to go hand in hand in the decarbonization journey.

lesser tried options including WASP and new fuels (© DNV)

Fuel cells are more efficient than diesel engine gensets, and can run on a wide variety of fuels, including LNG, ammonia, and of course hydrogen. The two big advantages are high prices (which are expected to come down) and slow start-up response (which is typically mitigated by also installing batteries to supply required extra e-power during start-up and power peaks). Both fuel cell technology and battery technology are evolv-ing dynamically, and installed power enjoys »exponential growth«, a term frequently used at HIPER and after three years of COVID only too familiar to all of us.

Syb ten Cate Hoedemaker (Maritime Battery Forum) gave an overview of the current status of maritime batteries and a bright future outlook. Prices continue to come down, and size and number of installations go up. The focus is on short sea shipping, such as ferries and work boats, which can recharge frequently and where the battery weight for the required kWh is not excessive. An example was the innovative e-powered ice-breaker design with an unconventional asymmetric shape, presented by Thomas De Nucci (US Coast Guard Academy). The design reflects another trend due to global warming: As the Arctic ice continues to melt and waterways become more navigable, the demand for icebreaking services including channel clearing, search and rescue and vessel assistance will only increase.

WASP

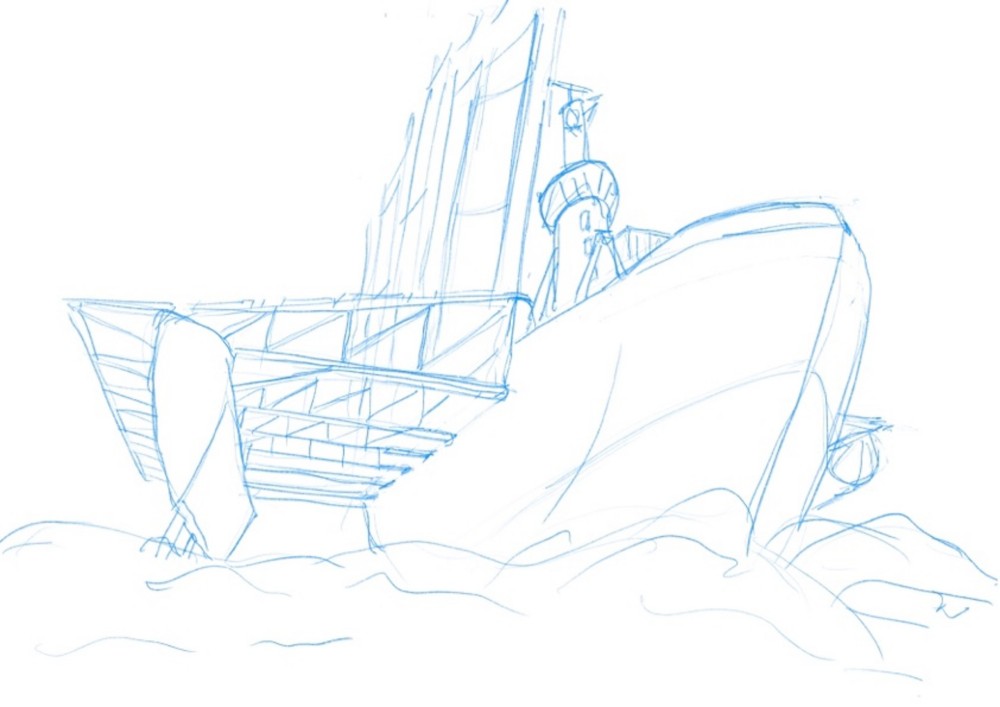

Despite the summery temperatures in the Tuscan venue, there was not a single wasp seen. But everybody talked about WASPs, wind-assisted ship propulsion systems, de-noting collectively anything that harnesses the wind directly to save fuel on propulsion. There is a plethora of proposed WASP system designs, some with a long history, some still at the idea and artist-vision stage. WASPs have also enjoyed exponential growth over the past few years, not just in websites and publications, but also in installations. The basic idea is appealing, and the images catch the eye, but take-up of WASPs so far has been lagging behind the hopes of many in the community. Why is that? The question was discussed in the forum and at least some answers were given.

WASP systems are treated by the industry like any other option to reduce the carbon footprint for ships, both on paper (what IMO credits for the EEDI/EEXI) and in reality (what performance monitoring shows in terms of fuel saving over longer periods of operation). Energy managers in the shipping industry then look at business cases for their fleet and prioritize accordingly, and the finance sector, following the Poseidon Principles, does similar management by numbers. In principle, this is a fine modus operandi to decide on investments – and tried-and-proven as our industry likes it.

But for any WASP system, the business case is complicated. It may be very good, but comes with high uncertainty. Expected winds and operational speeds affect the resulting fuel savings in a highly nonlinear way – a factor 30 in the saved fuel is not impossible, to give an idea. But neither managers, nor bankers, nor IMO like an honest »it de-pends« answer in assessing fuel saving options.

For the EEDI, IMO has tried to simplify design assessment with a »wind matrix« to as-sume for a given design. The recently adopted MEPC.1-Circ.896 (77) EEDI Guidelines for Wind Assisted Ship Propulsion (WASP) devices updated the previous procedures allowing new, device-specific selection of wind conditions. The intent, no doubt, was good, but the effect may not be the optimum in adopted measures for the global car-bon footprint of shipping. Francesco Stella (Computed Wingsails) sees the latest IMO guidelines as a modern-day Aeolus Bag (as in Greek mythology Aeolus offered a bag to Odysseus to take his pick of favourable winds): »New EEDI scores seem to be skewed in favour of some WASP technologies, and not commensurate to expected, real fuel savings delivered by wind propulsion. This can favour the development of WASP devices that offer great EEDI improvements based on the regulatory selection of favourable winds, rather than on real fuel savings.«

Green is Smart, Smart is Green

The example of the IMO WASP guidelines is just one incidence of a fundamental, larger issue. How do we fairly compare a larger set of energy saving options, which have different costs and different saving potential, which in turn may differ over time or for different operational parameters, and all that with typically limited information and time?

The answer seems to lie in resorting to time-honoured strategies in design and operation of ships: use experience, condense it in software (in modern parlance meta-models) and live with good estimates rather than perfect accuracy. Frederik Gerhardt et al. (SSPA) proposed exactly that in their contribution »Levelling the Playing Field: A Numerical Platform for the Fair Comparison of Different Wind Propulsion Systems«, using extensively model test data.

The purpose is to provide guidance for shipowners at the early concept stage of a vessel and help them select a system that suits their particular requirements. I guess the approach is the best we can do – for now. With time, we may get more insight into in-field performance of assorted green technologies for shipping, using performance monitoring and many ships, also before and after retrofitting. Josef Camilleri (Silverstream Technologies) presented pioneering work in this respect, for their air lubrication sys-tem, as such in-service demonstration of energy saving is vital for wider and faster adoption of the right technologies. »We believe that ship owners will welcome a more universal data collection method to evaluate and compare the different technologies available on the market,« explained Camilleri.

An often-overlooked potential for significant fuel savings lies below the water in the biofouling protection – which should ideally be sustainable without biocides and effective over a long period, even at zero speed in port or when laid up. Ultrasonic biofoul-ing protection can be seen by now as a tried-and-proven technology for niche areas such as sea-chests and side thruster tunnels.

But the market-leader Hasytec is ready to jump to the next game level. Xavier Mayorga (Hasytec) outlined the vision of ultrasonic antifouling for complete hulls of large ships, as targeted in the EU project CHEK for a bulk carrier and a cruise vessel, and the enabling technology which uses Artificial Intelligence in each sensor to optimize the parameter settings for actual ambient conditions, increasing the effectiveness of the transducer systems. Smart and green, indeed. And more ideas are waiting in the wings, ready to be tried out on ships. Philips and Akzonobel have developed an antifouling solution based on embedded foils emitting ultraviolet radiation; Fraunhofer, a method that irradiates fouling with blue lasers to clean hulls, destroying the fouling without damaging the coating.

Visionary goals inherently come with the risk of overlooking the opportunities close at hand. Optimization is well accepted best-business practice already, so why not apply it to next-generation ship designs? The idea was obviously in the air, as presenters from three continents presented related work.

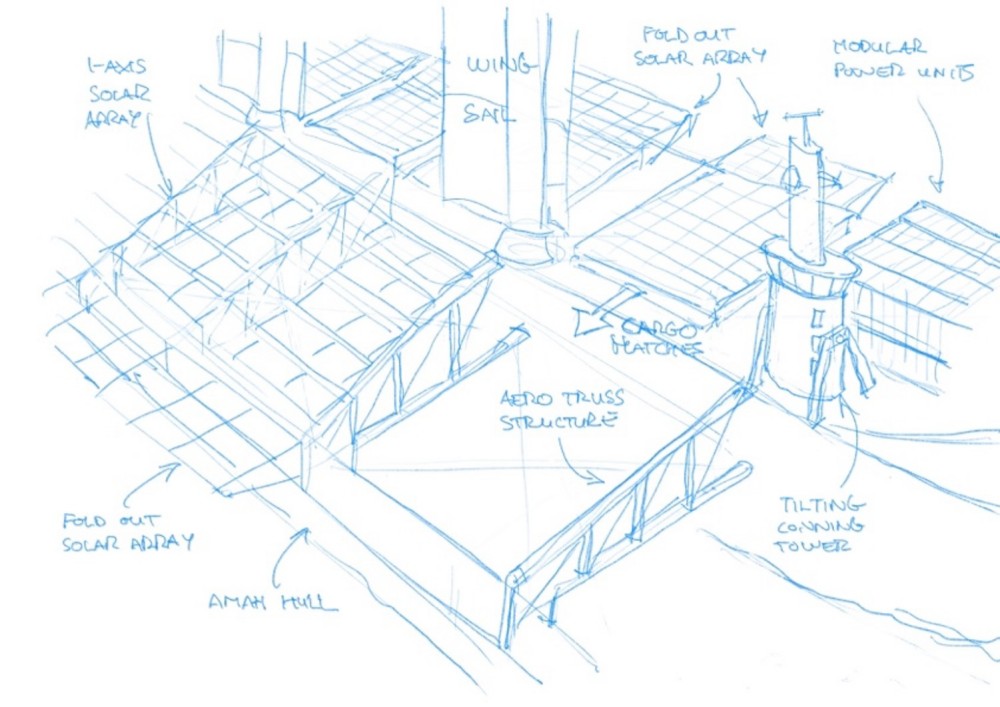

Kenneth Goh (Knud E. Hansen) from Australia presented an innovative platform for optimising renewable energy (solar and wind) powered ships. Fabian Thies (Chalmers TU) from Sweden, hull form optimization for wind-powered and wind-assisted ships, and Ruben Paredes (ESPOL) from Ecuador, the application of formal optimization for a zero-emission high-speed craft for Galápagos inter-island service.

Finally, the human factor in the decarbonization quest was addressed by Tracy Plowman (DNV), who presented effective digital training solutions to support the maritime decarbonization transitions, reminding us that we need to address awareness and expertise in the maritime community to enable the required changes towards decarbonization.

The proceedings are free to download from www.hiper-conf.info.