Ship design software today is not only about finding better hull shapes and making more accurate calculations. The Conference on Computer Applications and Information Technology in the Maritime Industries (COMPIT) showed a clear trend towards smarter products capable of much more. By Felix Selzer

At this year’s 16th COMPIT, taking place in Cardiff from 15 to 17 May, automation and autonomy were the prevailing[ds_preview] subjects discussed by the international experts. While some focused on smart ships, others looked at smart solutions already at the design stage. Computers can calculate process amounts of data much quicker than humans – old hat. But now developers focus on creating not only quick but also smart software that handles an increasing number of objectives and that »thinks« out of the box.

One example prominent at COMPIT was the idea to take the internal architecture of vessels – the arrangement of compartments, systems and components – into account during the design process. Looking seprately at hull shape, internal arrangements and other areas may cause problems at a later design stage. David Andrews of UCL urged for a Building Block approach to address issues in the earliest descriptions of a design study. Siebe Cieraad of Defence Materiel Organisation used a design synthesis model for the efficient design of submarines. Also based on a packing approach, their solution automatically generates »varying yet balanced« designs.

Mark J. Roth and his colleagues from TU Delft developed a new scoring metric to quantitatively assess qualitative properties of different arrangements that were generated with the TU Delft packing approach. This method enabled them to directly compare concept designs. The aim is a semi-automated assessment of designs. Picking the best design from tens or hundreds of possible designs »by hand« is time consuming.

Also Ted Jaspers from TU Delft thought, why not let an algorithm do some of the work? He and his colleagues came up with a clustering algorithm to bring order to ship designs generated by the TU’s packing approach. The aim was to find »families« of designs. The approach still has to be developed further, but the clustering already allows looking at designs from a different perspective. »We have hundreds or thousands of design variants with hundreds of features. When we manage to break them down into ten to 50 families, a naval architect can look at them in an efficient way,« Jaspers said.

Creating a smarter design process was also the topic of Greta Levišauskait and her colleagues from NTNU and Ulstein Design & Solutions. They looked at ways for efficient 3D modelling while keeping control of the product lifecycle at the same time. Thus, they successfully tried a 4th Generation Design (4GD) approach in shipbuilding, combining design and product lifecycle management (PLM) software in one environment. »Instead of a parent-child relation between components, nothing is fixed in 4GD. Each new design step can cause changes in previous designs,« she explained.

Rachel Pawling of UCL wanted to »expand the scope of early stage computer aided design.« Instead of using bespoke software solutions, she and her colleagues propose using ubiquitous desktop computers to applied methods from outside naval architecture to make wider use of queuing theory, real options theory online tools and virtual reality (VR). »We use 21st century tools but 19th century methods,« Pawling said.

Henrique Gaspar of NTNU called upon his ship design peers to use JavaScript for their design solutions. The programming can be done in web browsers and compatibility with older version is secured. Multidisciplinary and multi-objective – this could be used to describe a current trend in ship design.

Dejan Radosavljevic of Siemens PLM Software promoted his idea of a digital twin, complexity of modern vessels increases, saying: »We witness a shift from products being mechanical devices to being smart systems.« Simulation strategies should become predictive instead of being reactive and consider the scope of interaction between subsystems. Patrick Müller of Siemens gave an interesting example of how the idea of a digital twin works in reality, when he ended his presentation on data mining and the future of condition monitoring with a demonstration of Siemens’ eSiPod monitoring service that tells the engineer what is wrong and what to do and where to find the parts in question (read more in HANSA’s September edition).

Not only software but also systems are getting smarter. Carl Hunter of Coltraco Ultrasonic looked into possibilities of improving fire safety on ever larger and complex vessels by applying sensor technology. With a growing trend towards automation, sensor technology for system monitoring becomes increasingly important. But the amount of data and the security of connections is still a major concern. Anna Lito Michala and her colleague proposed a smart wireless system condition monitoring data. Pre-processing reduces the amount of actually transmitted data, and the smart system can prioritize more important data.

Scott Patterson of Babcock asked himself, how to deal with increasing complexity on board vessels. »Should we hire smarter people? We already hire the smartest people. So we need advanced systems to make them even smarter,« he said. He presented a study on secure wireless options for ships, noting that it is not necessarily about cyber threats, but about data confidentiality, integrity and availability. But still the human is the weakest element in the data security equation, Patterson stressed.

Human error is often used as an argument pro high-level automation or autonomy of ships. For some applications, unmanned operation is the only option. Fraunhofer Institute currently takes part in a Shell contest for the development of a fleet autonomous surface and underwater vehicles (ASV and AUV) for ocean floor mapping. Apart from the competition, presenter Gunnar Brink noted that the project can show how such developments of new technology can be made in an efficient way.

The aXatlantic project of Heinrich Grümmer – an idea born »over a beer with friends« – intends to send an unmanned vessels across the Atlantic. But one that actually will arrive on the other side. Grümmer went for simulation-driven, multi-objective design of both the hull and the propeller in CAESES and MAXSURF and came up with a solar powered self-righting ASV design. The hull already has been built, solar modules and engine are under construction.

As autonomous operation becomes also interesting for commercial vessel operation in crowded sea traffic areas, collision avoidance of unmanned craft was one of the major topics of the conference. Several groups of researchers looked into the possibilities of COLREG-compliant ASVs. Richard Daltry of ASV Global presented the findings his company made with their MAST platform’s collision avoidance system. He invited his colleagues to experiment with their systems on the platform that he is eager to test in an environment with »real-world-uncertainty«. Axel Hahn of the University of Oldenburg stressed the need for new testing and verification methodologies for the technical, ethical, legal and insurance issues: »We need a generic test bed platform.«

Jesus Mediavilla of Lloyd’s Register and his team working on the MAXCMAS project (machine executable collision regulations for marine autonomous systems) focused on how to translate COLREGs – written for human consumption – into collision avoidance algorithms. Future work will look i.a. into interaction of autonomous and manned vessels. The difference between robot and human behaviour triggered interesting discussions in the audience, time and time again. Azriel Rahav of Totem Plus presented his holistic approach to autonomy with the Totem Auto Navigation System (TANS) that controls navigation, machinery and power. He noted: »Consider the difference between autonomous and unmanned. Also without radio contact, a truly autonomous vessel must know what to do.« He welcomed the work of Hasan Deeb of University of Oldenburg who developed a pre-crash advisor for manned vessels, that provides decision support for shipmasters for mitigating collision damage. Ideas and products like this may not be in use today and as single products they will not enable autonomous shipping – but they will be the building blocks of autonomous vessels one day.

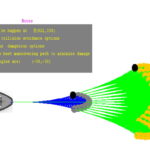

Yogang Singh and his colleagues of the University of Plymouth approached the subject of collision avoidance and path planning by looking at the possibilities of artificial potential fields in real time marine environments. Tests looked promising but raised an intersting discussion in the audience on whether the manoeuvering behaviour of such a vessel would be interpreted right by human shipmasters.

Although the classic shipyard topics at this year’s COMPIT were not as promiment as in the past, there were still some interesting projects on the agenda. On the software side, smart shipyard operation was a topic. Lode Huijgens of TU Delft showed how a work content estimation model based on historical data and design principals could optimize the ship building process. Yong-Kuk Kim of Seoul National University addressed the issue of delays in the logistics process for ships assembled in a block construction. The tools he and his colleagues have developed integrate block logistic loads into process simulation in the planning stage to provide for a smooth production process.

As at COMPIT 2016, possible fields of application of virtual and augmented reality (VR, AR) in shipbuilding were topics again. A team from the University of Turku tested the different available VR and AR products for potential industrial use and found some of the technology mature enough for that. COMPIT organizer Volker Bertram could not resist to ask whether VR was maybe just a solution that looks for a problem. Conference veteran Denis Morais of SSI, winner of the COMPIT award in 2011, admitted that VR maybe does not ten times improve traditional solutions but said: »VR will be more successful in shipbuilding than in the consumer space. It is not an extension of what we do but it certainly offers some benefits in areas like training, design review or laser scanning.« He estimated that the consumer market is still five to ten years away from a satisfying VR experience.

Christian Cabos of classification society DNV GL showed how technologies such as drones, self-localizing cameras and visual mapping could allow remote structural condition assessment in the future. As an example he named work intensive tank entries of surveyors that could be made unnecessary some day, but Cabos added: »This is just a possible application of all the technologies we are looking into at the moment.« First, all the VR amd 3D imaging research projects would produce useful spin-off products along the way.

Stephan Procee of Maritiem Instituut Willem Barentsz together with colleagues of TU Delft saw VR and AR as an opportunity for navigators that are confronted with increased complexity of today’s integrated bridges. A visual overlay could point out important signals that the shipmaster should attend and enhance the vague information that some technologies such as radar provide.

Time will tell which technology will be used in the end to make the work of shipbuilders and surveyors more efficient and safer. Shipbuilding company Ulstein sees a clear need for a modern, systemic and methodological approach to prepare for the digital future. André Keane gave an overview of the company’s strategy of using Big Data analytics. Ulstein already experiences higher productivity in design and higher performance of design solutions. »Develop fast to succeed or to fail fast and learn,« Keane put it.

Felix Selzer