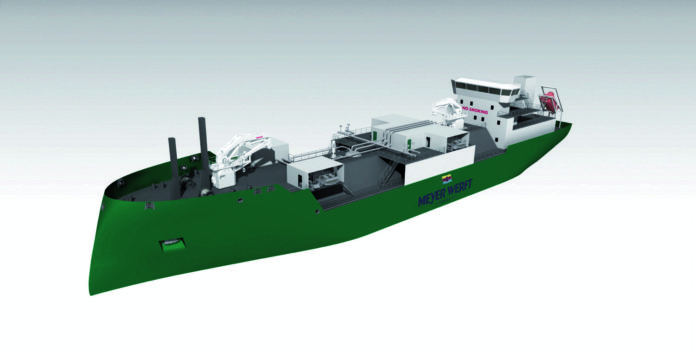

Meyer Werft has presented a complete design of a tank barge for[ds_preview] LNG (liquid natural gas). The shipyard takes part in several LNG-related research projects and provides the designs of the tank system, both of the receiving vessel and the LNG bunker barge itself as part of the national research project »Bungas«. In this framework the entire process chain starting from the LNG terminal to the bunkering of the LNG-receiving vessel was investigated in detail.

The barge is designed for a total of 5,000 m3 of LNG, which is spread over two storage tanks. It is 104 m long with a width on bulkheads of 18.4 m and 5,600 gt at a total draught of 5 m. Various refueling operations in accordance with IMO type A, B or C lead to different possible process chains. High flexibility allows for safe refueling at all IMO Code IGF-defined facilities at a maximum flow capacity of 50 m3/h. The maximum permitted capacity is 10 bar(g), based on the assumption that a ship with 2,000 m3 bunker capacity receives the LNG within five to six hours. Major components of the bunker station are a salient flange, a valve (ESD) and a manual shut-off valve. All pipe sections are protected by a pressure relief device. There is a drip tray of special design under the valve and flange assembly: The upper drip tray under the pipe is securely installed. The lower may be moved on a rail system. The tube saddle is firmly connected to the lower drip tray. Thus, the lower drip tray and the saddle tube are pulled away from the hull while driving. On demand the barge may perform the treatment of the gas directed back. The shipyard offers additional equipment based on the use of liquid nitrogen (LIN) in containers. The LNG storage tank on board the barge is a type C container with a permissible pressure of 4.5 bar(g). The capacity to increase the pressure up to 4.0 bar(g) provides an additional safety margin.