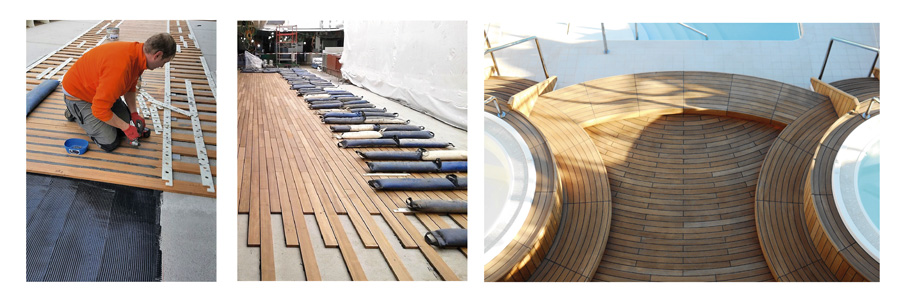

The ISOLCOL project: a new concept for wooden-covered decks

The ISOLCOL project, carried out by Consorzio Servizi Navali Industriali Scarl (Genova, Italy) and Fratelli Budai Srl (Villa Vicentina, Udine, Italy), with the collabora[ds_preview]tion of the Dept. of Engineering and Architecture of the University of Trieste, established the grounds for improving the acoustic and vibrational comfort onboard of large cruise ships and yachts. The project successfully developed an innovative, nanotechnology-based glue able to effectively dampen vibrations generated on wooden-covered decks, to the benefit of the underlying cabins.

The acoustic and vibrational wellness of passengers of yacht and cruise ships is becoming very important for ship builders and owners, as it influences greatly the guest experience. In particular, open decks paved with wooden tiles are aesthetically pleasant, but they can be source of vibrations for underlying environments, creating discomfort for the passenger.

The current state-of-the-art in wooden covered decks involves the use of polyurethane- or polysiloxanes-based glues. These materials are very effective in providing strong wooden tiles adhesion to the bridge, even in a chemically aggressive environment such as the marine one. However, their performance in terms of acoustic insulation is poor, leading to the necessity of fitting the decks with an additional layers of a viscoelastic material, in order to dampen vibrations and noise. The viscoelastic layer has a series of problems: it is combustible, heavy (about 3 kg/m2, for 2.5 mm of layer thickness) and it has a non negligible cost, in terms of both material and time needed for mounting it on (which, in turn, is a drag for the overall ship fitting activities).

To solve these problems, the Consorzio Servizi Navali e Industriali-CSNI from Genova/Monfalcone, the company F.lli Budai from Villa Vicentina (Udine) and the University of Trieste teamed up in the frame of a research project funded by the Autonomous Region Friuli Venezia Giulia, developing ISOLCOL, an innovative glue for wooden tiles.

The strong innovation brought up by ISOLCOL consists in a wise implementation of cutting-edge nanotechnological solutions applied to a marine regulations-compliant glue, achieving a „nano-glue“ able to solve the aforementioned technical problems. The ISOLCOL nano-glue is resistant to the marine environment, and it is able to effectively insulate the accommodation spaces underlying wooden bridges from both the acoustic and thermal points of view. In particular, it provides an acoustic insulation level so high that it is possible to completely eliminate the viscoelastic layer from the deck covering, still conserving the vibration dampening properties of a standard deck covering (characterized by the presence of both the viscoelastic layer and the traditional glue). In this way ISOLCOL realizes its objective, i.e. the elimination of the viscoelastic layer from the deck covering. Furthermore, the ISOLCOL nano-glue possesses also thermal insulation properties, making it the first known glue able to provide effective vibrational and thermal insulation all-in-one.

On top of all this, the ISOLCOL glue can be deposited using industry-ready spraying equipment, greatly improving and speeding up the ship fitting operations.

Summarizing, the most innovative functional features of ISOLCOL are the following ones:

- improvement of the thermo-acoustic isolation of the cabin underlying wooden-decks

- lower costs for ship/yacht fitting activities

- decrease of ship fitting times

- lower weight of decks, which in turn delivers lower fuel consumption hence ecological benefits.

The ISOLCOL nano-glue has been validated by a series of tests conducted both in laboratory and in realistic environments, and is currently being tested for industrial production, so to move the product towards commercialization for yachts e cruise ships building.