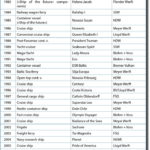

For the 28th time HANSA has selected the most interesting ship of the year. This prize is awarded to that particular newbuilding from a German shipyard that the HANSA editors consider the most innovative, technically interesting and from the production point of view most sophisticated vessel of t[ds_preview]he year just gone by.

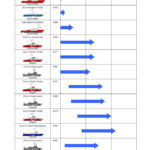

Looking at the ships selected for this award in the last 28 years it can be stated that they represent the development of German shipbuilding over almost three decades. All in all, there were eleven cruise ships, five container vessels, four ferries, two research vessels, two reefers, two yachts and one naval craft. It can also be observed that over this period of time the individual ship types have become much more specialised: general cargo ships have developed into innovative container vessels, standard cargo or ro-ro ferries into modern con-ro or ro-pax ferries and the cruise ships of the youngest generation are highly sophisticated floating holiday resorts. And last but not least, the construction of mega-yachts has grown into a very significant field of German shipbuilding.

The winner of the »Ship of the year 2009« Award is the new 60 m SWATH-Pilot Station ship »Elbe« by A & R. This ship is representative of the SWATH design by A&R in the third generation. In commercial shipbuilding unconventional ships of smaller dimensions have found application in recent year. These ships were SWATH, originally invented with the purpose of reducing wave making resistance. The development of modern catamarans has overtaken the SWATH concept in this area. The SWATH ships on the other hand made it their aim to exploit their inherent potential extraordinary sea-keeping capabilities.

More than 100 years of ship-building experience

The shipyard Abeking & Rasmussen (A & R), situated on the banks of the river Weser, was founded in 1907. Over the decades, it has evolved to a state-of-the-art shipbuilding complex, currently consisting of five hangars for ships of up to 80 m in length, modern office buildings and an inner harbour. It is equipped with a syncrolift. There are environmentally friendly workshops housing high-performance facilities for producing conventional steel, aluminium and non-magnetisable steel ships.

The century-old dream of the seafarers not to be exposed to the forces of the wind and the movement of the water during a sea passage now is much closer to coming true. It has always been the aim to enable people to work upright onboard vessels instead of crawling »on all fours«. Already quite some time ago systems were invented – particularly in connection with passenger ships – to reduce the rolling and pitching of the vessel’s hull in rough seas: anti-roll tanks and fin stabilizers. These very complex and expensive devices – which are still always subject to physical laws and sometimes even deteriorate the vessel’s behaviour – did, however, not really prove useful on ordinary ships. Thus normal vessels, especially smaller units, remain dangerous working places to seafarers and prevailing conditions on board can always impair the efficiency of seamen to perform their duties appropriately. A & R achieved a »quantum leap« when the yard introduced its state-of-the-art computer technology for the future, the SWATH concept. Even on board smaller vessels crews today can be provided with a stable platform.

The SWATH-Technology

The SWATH-Technology has been known in Germany since 1930 and was registered as patent. It is based on the knowledge that wave resistance declines when as much displacement as possible can be brought below. The lower resistance level is achieved by skilled overlapping of the wave profiles generated by the various displacement levels. This design underwent a consequent development by A&R according to the specific requirements of the customers. The Pilot Station ship mentioned above is also being called a »North Sea Hotel« owing to its outstanding characteristics at sea.

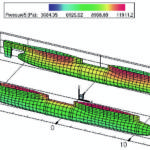

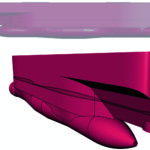

SWATH stands for Small Waterplane Area Twin Hull, an innovative hull concept for smooth service in rough seas. The buoyancy of a SWATH ship is provided by its submerged torpedo-like bodies, which are connected by single or twin struts to the upper platform. The cross-section at sea surface level is minimized and thus only a minimum of the ship is exposed to the lifting forces of the waves. The idea of SWATH was taken from the principle of semi-submersible offshore rigs which are designed to provide a working platform with minimized motions in open sea.

The first demonstration SWATH was launched in the Netherlands in 1968. In the US a ship with 200 t displacement was commissioned by the Navy in 1972; initially reported problems were caused by »trial and error« approaches. Given today’s possibilities of computer technology, sophisticated and optimized SWATH design are now feasible; motions in rough seas can be predicted and reliably tuned during the project phase – by those who know how!

A & R has developed SWATH Technology systematically on the background of its longstanding experience in hydrodynamics, lightweight construction, special materials and leading edge ship design.

With the know-how gained from full-scale service data of reference ships and special software tools today A & R is in a position to design and deliver SWATH ships reliable for tough everyday duty – a long-term valuable investment – under the brand name SWATH@A&R. Since 1994 the shipyard has been concentrating on the second generation and developed and built two pilot tenders which were delivered to their owners in 1999. Since then these ships have successfully proven the capability of the SWATH-design in service under deployment of the Cuxhaven Pilots’ Association in the estuary of the Elbe river up to the island of Heligoland.

The technical designs of the pilot tenders slightly differ from each other, as the experience of the first ships was included in the construction of the new vessels. The description here below refers to the first SWATH@A&R Ships »Döse« and »Duhnen« of the Cuxhaven pilot association.

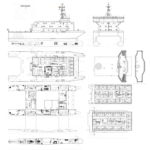

The vessels, also entirely made of aluminium, have a length of 25.65 m, a beam of 14.26 m, a draught 2.7 m and a displacement of 125 t. The propulsion plant is diesel-electric and operates according to the electric shaft principle, with energy generation provided in the area of the main deck via two plants with MTU diesel engines of type 12V 2000 M70, each developing 788 kW. The two torpedo floats accommodate the electric drive engines, which are run with changing speeds and act via a gearbox on the shaft with fixed pitch propeller. The very course-stable and extremely manoeuvrable ships reach a top speed of 18 knots. The pilot tenders have a crew of two persons and can take up to eight pilots. They are designed for an average wave height of 3.5 m. However, they also allow pilot transfers with maximum wave heights of 5 m. A computer-controlled fin stabilisation keeps the ship horizontal. Heelings can be generated via a fast ballast system. Transfer operations are thus also possible on vessels with low freeboard.

A transfer up to 6 m above the sea is feasible. The SWATH@A&R pilot tenders have the Germanischer Lloyd classification GL + 100 A5 OC 3 Pilot Tender.

The SWATH@A&R pilot station ship »Elbe« (today »Hanse«) was commissioned a year later, in August 2000. Unlike the tenders, the SWATH@A&R pilot stations have a steel structure with 49.90 m length, a beam of 22.55 m, a draught of 5.90 m and a displacement of 1,480 t, designed as an all-electric ship. The »Hanse« was equipped with four diesel generators with engines of type MTU 8V 396 TE 54 with a propulsion output of 2,00 kW, installed in pairs in the floats, as they are electrically driven engines. They each develop 1,000 kW to drive the shaft with a fixed propeller, providing a top speed of 14 knots. The bunker capacity is also designed for supplying the pilot tenders.

The main objective of the design was to achieve an optimal form of the torpedo-shaped floats that provides minimum resistance and simultaneously retain the required seaworthiness. An intelligent propulsion system was integrated on the all-electric ship. Its basic design had non-active steering fins installed on the floats with no increase of resistance. During tests it turned out that compared with a conventional ship the 25 m SWATH-design showed entirely superior characteristics. Under conditions of wind force 7–9 (in squalls up to 9) and waves up to 4.3 m the twin-hull construction remained in vertical acceleration below 0.2 g, and rolling was below 5°. The fast displacement ships of the SWATH type show a lesser wave making drag for Fn > 0.3. For another design variant of the 25 m SWATH tender the resistance in actual dimensions shows that for the higher speed of 20 kn and Froude number of 0.65 the resistance compares very favourably to a monohull.

The tested and economic SWATH pilot tenders and pilot station ships have meanwhile been in operation for many years. With their sea-keeping capacity they are capable of maintaining their velocity of 18 kn when transferring personnel to the seagoing vessels at 10–12 kn compared with 6 kn of conventional tenders and ensures a rapid succession of pilot attendance. Furthermore they do not have to navigate into the lee of the ocean-going vessel but can continue operations even under weather conditions with west-north-westerly winds at Beaufort force 9 and up to hurricane strength with southern or easterly winds in the Elbe river estuary. This does not only save time but also an expensive and (still) dangerous pilot transfer by helicopter.

These obvious advantages triggered follow-up orders from other pilot associations. Two more tenders entered service in the Weser estuary in 2004 and for the river Ems in December 2006. Another two pilot station ships are going to be commissioned in 2010. In 2005 and 2006 A & R delivered two pilot tenders to the Nederlands Loodswezen. The decision for the SWATH technology was based on the good operational experience of the German pilots: The Elbe Pilot Association operates in the North Sea off Cuxhaven 25 m SWATH@A&R Pilot Tender and a 50 m SWATH@A&R Pilot Station Ship since 1999. These vessels perform their duty in a tough workboat application all the year round – under all weather conditions. Since these ten years pilot operations became safer and more cost efficient. This reference is confirmed by the Dutch pilots who operate one of their 25 m SWATH@A&R Pilot Tender on the river Scheldt.

In May, 2009, the Flemish Prime Minister Kris Peeters signed a contract for a new Pilotage System in Brussels for the Flemish sea ports. The financing was achieved through a Public Private Partnership under the auspices of the Dexia group. Abeking & Rasmussen will deliver three 25 m SWATH@A & R Pilot Tender and one 60 m SWATH@A & R Pilot Station Ship in 2011 and 2012. In 2008 A & R applied the successful SWATH principle even when building a mega-yacht for a private owner. »Silver Cloud« is the first and up to now only yacht of her very special kind (see HANSA 8/2009, page 16–20).

The SWATH@A&R technology of Abeking & Rasmussen was chosen from a worldwide competition. Including these new Pilot Vessels, Abeking & Rasmussen has meanwhile delivered or contracted twenty SWATH vessels for customers worldwide, which prove their leadership in this sophisticated technology.

GF