The first Tier-II compliant MAN B&W engine has finished production[ds_preview] at HHI-EMD (Hyundai Heavy Industries Engine & Machinery Division) in Korea and is ready for delivery. The low-speed, two-stroke MAN B&W 6S50ME-C7 type engine will power a shuttle tanker (hull number 1749), currently under construction by Samsung Heavy Industries Co., Ltd., and ordered by Teekay, global provider of marine services to the oil and gas industry. Ship delivery is planned for July this year.

Under the terms of the contract, the 6S50ME-C7 engine is intended for Teekay’s Amundsen class of ships, the most sophisticated and eco-friendly shuttle tankers ever built. Teekay actively sought for production to meet DNV (Det Norske Veritas) Clean-Design Notation requirements that comply with the strict, IMO Tier-Il emission limits, setting in train the production of the first Tier-II compliant MAN Diesel engine.

Environmental Milestone

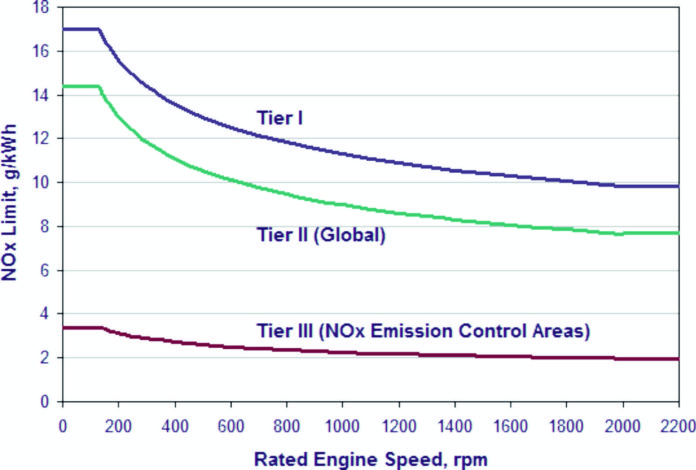

This milestone is related to MAN Diesel’s decision in June 2008 to relaunch its product portfolio, making all its engines compatible with the limits established by the International Maritime Organisation (IMO) in its Tier-II regulations. The historic relaunch was designed to pre-empt the January 2011 implementation of the new IMO NOx emission limits and clearly flags the company’s environmental credentials.

Tier-II compliance process

Søren H. Jensen, Vice President and Head of Research & Development, Marine Low-Speed, MAN Diesel states: »This is the first customer engine that has been converted and we are also well underway with the remainder of our two-stroke portfolio, which will be Tier-II-ready in its entirety later this year.« He continues: »We know exactly what each engine requires and making them Tier-II-ready is only a matter of fine-tuning them on the testbed. In this respect, we have already finalised agreements with our licensees to set aside the necessary time-slots for testing.«

Jensen goes on to praise the role MAN Diesel’s licensees have played: »I would like to underline that we are carrying out this compliancy programme in full cooperation with 2/2010 our licensees. This is only possible with their help as our broad portfolio means we cover a lot of engine segments, which in turn means there are a lot of engines that have to comply with Tier-II’s tough emission legislation.«

The majority of adjustments required to make the engines compliant with Tier II are minor, internal changes influencing such characteristics as scavenging pressure, injection spray pattern and smaller combustion-room volumes.

Jensen says: »There are a lot of positives for customers here: they will get well-known, reliable technology that is optimally tuned and, as such, represents no investment risk. All changes are internal and customers won’t notice any difference to the way the engines are run – everything will just continue as normal.«

Rate-shaping

In fact, Tier II shows the great advantage of MAN Diesel’s ME-engines. Jensen states: »Traditionally, lowering NOx levels requires an increased fuel consumption but, with ME-engines, this can be minimised due to their rate-shaping injection profile capability. This provides for unlimited possibilities to adjust the injection profile compared to the on-off method favoured by common-rail engines.«

He concludes: »The market should also know that despite being currently occupied with Tier-II compliancy, we are already looking beyond it to the next step, that is, Tier III, and full compliancy with its stringent emission levels by 2016.«