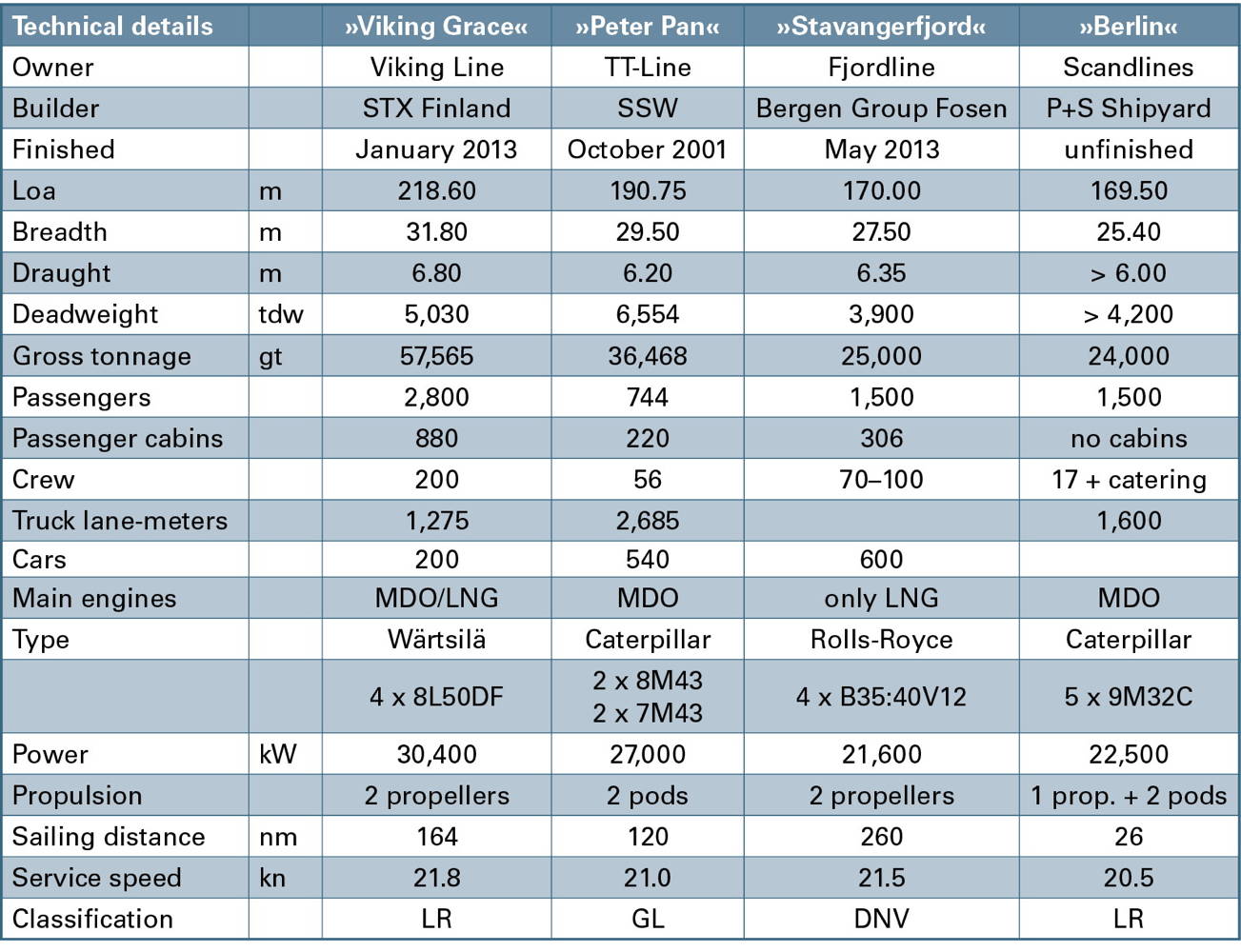

Early this year, cruise ferry »Viking Grace«, fuelled by LNG, started her service between Stockholm and Turku. In June, ro-pax ferry »Stavangerfjord« will start her service between Hirtshals and Stavanger/Bergen, also fuelled by LNG. Other electric driven ferries for shorter distances are projected for less harmful emissions.

In his analysis »Environmental regulations towards 2020« Erik Nyhus, Director Environment of Det Norske Veritas, states: »The increased focus on[ds_preview] both global and environmental issues in general, combined with the growing realization of the actual pollution burden imposed by shipping, has led to an upsurge in both international and national regulations. Some are ready and will enter into force in the very near future, while others are still being developed and will have impact only in the intermediate term.«

The key issues that will have a significant regulatory impact this decade are, broadly speaking, sulphur oxides (SOx), nitrous oxides (NOx) and particles (PM), greenhouse gases (particularly CO2), as well as ballast water management.

Emission Control Areas

SOx, NOx and PM are all emissions to the atmosphere that result from the combustion of marine fuels, amongst others. The local environmental effects of these are generally well- known and include acidification and eutrophication, both of which have potentially severe ecosystem impacts and negative health effects on exposed populations. The impacts are generally well understood and have in some parts of the world (e. g. Europe and USA) led to the strict regulation of emissions from land-based sources.

In recognition of shipping becoming a dominant emission source, emissions have been internationally regulated by IMO through the MARPOL Convention. This gives a combination of general maximum global emission levels and significantly more stringent levels applying to designated sea areas generally known as Emission Control Areas (ECA). The regulations allow emissions to be mitigated by either changing the fuel type or cleaning the exhaust gas.

There are certain key dates that represent crucial regulatory deadlines for shipping:

• January 2015: 0.1 % S in ECA

• January 2016: NOx Tier III in ECA

• 2020 or 2025: 0.5 % S as global cap

Prior to 2015, operators have the choice between installing technically complicated and probably expensive exhaust gas cleaning systems (scrubbers) or switching to low-sulphur fuel for all ships operating in an ECA. Low-sulphur fuel options will realistically be either expensive distillates or LNG, the latter in practical terms being an option mostly for newbuildings.

For ships built in 2016 and onwards and operating in an Emission Control Area, the NOx requirements add another layer of complexity due to possible difficulties in technically integrating SOx and NOx solutions. Finally, in 2020 or 2025 (pending on the IMO decision in 2018) the 0.5 % S global cap will enter into force, changing the economics of the decisions made in the preceding years (At the recent MEPC session in May it was considered and agreed to amend the date for implementation of Tier III standards within ECA to 1 January 2021, from the current effective date of 1 January 2016. The draft amendments will be circulated for consideration at MEPC 66 in 2014, with a view to adoption.).

Current fuels

The most widely used fuel worldwide for oceangoing ships is HFO, a by-product of crude oil processing which therefore contains a certain proportion of sulphur derived from the crude oil. Compared with this, the sulphur content of marine diesel oil (MDO) is lower, as it is a distillate. MDO is rarely used as fuel for large marine diesel engines, because it is about 80 % more expensive.

According to information from DNV Petroleum Services, the average sulphur content of all fuels used in the second half of 2007 was 3.53 % in the Middle East and 2.62 % worldwide. There are now various techniques available that make it possible to reduce the sulphur content of HFO to about 0.5 %, but not much more below that. MDO used for sea transport has a maximum sulphur content of 0.1 %.

With effect from May 2006, IMO designated the Baltic Sea the world’s first marine area to be subject to tighter restrictions on the sulphur content of fuel. Within this ECA, marine fuel must not contain more than 1.5 % sulphur. Since August 2007, the same rules also apply in the North Sea. This made it necessary for ship operators to act, and especially German TT-Line acted and became a pioneer in efficient and environmentally sound transportation of people and goods across the Baltic Sea.

Eco-pioneer TT-Line

For years now, German TT-Line has been implementing solutions for an environmentally sound ship operation, as far as this was economically possible. Since 1995, the company has introduced four newly built ro-pax ferries with an environmentally friendly diesel-electric propulsion system, naming them »Green Ships«, two of them with innovative pod propulsion.

Unlike conventional drives, where the diesel engines transmit their power directly to the shaft lines, diesel generators on board these four TT-Line ships produce electric power for all the shipboard requirements, just like a power station. Even the ship’s propellers are driven by two large electric motors. This has the advantage that diesel engines can run with constant speed at best possible load. This ensures always low emissions even during unfavourable operating conditions of the vessel.

Consequently, when running part load (e. g. during manoeuvering in port or during approaching), the diesel-electric propulsion will reduce NOx emissions by up to 50 %. At the same time, emissions of carbon monoxide (CO), hydrocarbons (HC) and PM are considerably reduced.

The pod drives of the latest two diesel-electric ro-pax ferries »Peter Pan V« and »Nils Holgersson VI« represent a further technical innovation. In pods, the electrical propulsion motors and the propellers are fitted in azimuthing gondolas, which are positioned underwater at the stern. Compared to conventional propulsion systems, these so-called pods achieve fuel savings of up to 15 %. Consequently, climate-damaging CO2 emissions are reduced while at the same time manoeuvrability is considerably improved.

Viking Line’s »Viking Grace«

Since 10 January 2013, the new cruise ferry »Viking Grace« sails between the city of Turku on the Finnish West Coast to the Swedish capital Stockholm and back again. The journey via the Åland Islands takes about 15 hours.

The new ferry is described in detail in this issue (p. 36 ff). It is by far the largest vessel of its kind and fuelled by LNG. Another novelty is the vessel’s electric propulsion drive. According to Viking Line, an electric vessel fitted with generators and electric propulsion machinery today is more economical than using diesel-mechanical drives.

The ferry has four 7,600 kW Wärtsilä 8L50DF dual-fuel engines, each coupled to an ABB generator producing 8,191 kVA at 500 rpm. Two ABB ACS8 synchronous electric propulsion motors each create a propulsive power of 10.5 MW at 0–128 rpm. There are two shafts with fixed-pitch five-bladed propellers in front of flap-rudders.

For good manoeuvering one 1,500 kW stern- and two 2,300 kW bow-thrusters are installed. The planned service speed of the ship is 21.8 kn. Even with only two out of the four generators powering one propulsion motor with a third generator running for the hotel-load and the fourth engine under service the vessel is still able to reach 15 kn.

Fjord Line’s »Stavangerfjord«

By 14 July, Norwegian Fjord Line plans to put into service »Stavangerfjord«, the first of two new medium-sized ro-pax ferries presently under construction at Bergen Group Fosen shipyard in Rissa near Trondheim, Norway. The sister ship »Bergensfjord« is to follow in autumn. Both hulls were constructed by Polish Stocznia Gdansk Shipyard and towed to Norway for final outfitting. Originally the ferries were designed to be powered by high-efficient common rail diesel engines. In summer 2012, however, Fjord Line announced that they would change the engine plants into »single-fuel« machinery, each with four Rolls-Royce (Bergen Diesel) B35:40V12PG with four 5,700 kW (MCR) power and fuelled only by LNG.

Once they will be delivered, these ferries are claimed to be the first seagoing ro-pax units to operate on gas engines solely fuelled by LNG. The contract for the engine plants was awarded to Rolls-Royce Marine, Norwegian section. The company also supplied the two 296 m³ LNG tanks with Acon-Gas control system for each vessel. The emissions produced by the engines will be reduced by about 90 % of NOx and by 23 % of CO2 content and will not contain any sulphur or heavy metals. The propulsion systems will enable the ferries to cruise at an operating speed of 21 kn.

The vessels can each accommodate 1,500 passengers in 306 cabins comprising standard cabins (11 m²) as well as luxury suites (19 m²). Rolling cargo of 600 vehicles altogether can be stored on the main deck as well as on hinged car decks. Both hulls comprise ten decks each; deck 8 and 9 are the accommodation decks with two levels of decks with five restaurants, four bars, six conference rooms, two playrooms, a tax-free shop and a casino below of them.

Bergen Group Ship Design and Bergen Group Fosen were entrusted to provide the design of the vessels. Finn Falkum Hansen was appointed as architect for the project. The contract to supply the 300,000 t of LNG needed per year to fuel the engines has been awarded to Skangass. Deliveries of tax-free goods will be overseen by Gebr. Heinemann, Hamburg. This contract includes retailing of perfume, cosmetics, clothing, alcohol, tobacco, delicacies and other commodities.

Fjord Line was established in 1993 and today has 245 employees, 85 of which work ashore in Bergen, Stavanger, Egersund, Kristiansand and Hirtshals and 160 at sea year-round, mainly on board the »old« smaller ro-pax ferry »Bergensfjord« and during summer season on board fast catamaran (HSC) »Fjord Cat«. During high season (from April to September) the workforce increases by about 100 employees.

Currently, the old »Bergensfjord« sails from Bergen/Stavanger in Western Norway to Danish Hirtshals until the new »Stavangerfjord« takes over in July. Old »Bergensfjord« will then undergo extensive upgrading before it will begin service on the new route Fjord Line is starting between Norwegian Sandefjord and Swedish Strømstad. HSC »Fjord Cat« operates the express line from Norwegian Kristiansand to Danish Hirtshals during the extended summer season.

Scandlines’ »Berlin« and »Copenhagen«

Fjordline’s two new ro-pax ferries (25,000 gt) are similar to Scandlines’ traject ferries »Berlin« and »Copenhagen« (24,000 gt) only in size. The Fjordline ships are cruise-like ferries with cabins for overnight passengers and the ability to carry rolling cargo or up to 600 cars. Their sailing time will be more than twelve hours. The new Scandlines vessels are typical short-distance ferries for day passengers and a maximum of rolling cargo on board on two decks with truck height. Loading and unloading is done on two levels via shore-based ramps.

Originally, the ferries »Berlin« and »Copenhagen« were scheduled for delivery in late spring and summer 2012. Due to technical and financial troubles, P+S Shipyards with their facilities in Stralsund and Wolgast had to file for insolvency on 29 August 2012 (see HANSA 02/2013, Supplement, p. 6). In the meantime, the Wolgast yard has been sold to Lürssen Shipyard while Stralsund remains insolvent. They continue to finish two ro-ro cargo ferries for Danish DFDS, of which the first one was rolled out of the building hall and launched via ship lift on 19 April 2013. Scandlines cancelled the contracts for »Berlin« and »Copenhagen« and another buyer has not been found yet.

Innovative ferries for CMAL

Early last summer the Scottish shipping company Caledonian Maritime Assets Ltd. (CMAL) placed a contract with Flensburger Schiffbau-Gesellschaft (FSG) to design and build a new ro-pax ferry type. This ferry, recently named »Loch Seaforth«, will go into service in 2014 between Stornoway and Ullapool linking the mainland of Northwestern Scotland with the Isle of Lewis in the Outer Hebrides.

Because of her high value and modern design and construction the ferry will be capable of round-the-clock operation and thus will replace two local ferries. She will be 116.60 m long, 17.40 m wide, accommodate 700 passengers and boast 372 m lanes for 143 cars or 26 trucks. She will have a deadweight of 1,500 t and a tonnage of 7.800 gt.

FSG’s requirements for the engine plant on board were that the engines must be commercially competitive, compact and light in weight. Wärtsilä will deliver two eight-cylinder in-line Wärtsilä 32 main engines and three eight-cylinder in-line Wärtsilä 20 gen-sets. The total weight of this equipment will be just 151.4 t which is the lowest in this class. The low engine weight contributes to the low overall weight of the vessel itself which results in a relatively high payload. Good fuel efficiency and low emission level were further important considerations in the selection process.

In addition to the ferries CMAL also owns the ports, harbours and infrastructure for the ferry services connecting the West Coast of Scotland and the Firth of Clyde. The company is a wholly owned public corporation of the Scottish government, with Scottish ministers as sole shareholders.

Today, CMAL owns all the vessels, land-based assets and the Caledonian MacBrayne brand and makes them available to an operator through an open tendering process. CMAL currently owns 30 ferries, all of which are operated by Calmac Ferries and Rathlin Ferries on routes to the islands and peninsulas of the West of Scotland.

Besides this contract with FSG, CMAL is currently running some innovative projects. One is the hybrid ferries project: CMAL announced on 17 December 2012 that the world’s first seagoing ro-ro vehicle and passenger diesel-electric hybrid ferry was launched and named »Hallaig« at Ferguson Shipbuilders, Port of Glasgow on Clyde. The sister vessel »Lochinvar« was named and launched on 23 May 2013.

The ferries, to be operated by the current operator of the Clyde and Hebrides Ferry Services CalMac, are designed to be employed on many of the short crossing routes around the Clyde and Hebrides and use some of the most innovative new »green technologies« including battery banks (Imtech) supplying a minimum of 20 % of the energy consumed on board.

Each ferry is designed to accommodate 150 passengers, 23 cars or two trucks, with a service speed of 9 kn. Energy will basically be produced by three Volvo Penta D13 MG engines with 360 kW each. Two permanent magnet motors of 375 kW are coupled to two VSP 16 R5 EC/90-1 thruster units each. In addition, two lithium-ion battery banks with a total of 700 kWh will also be able to supply power – reducing fuel consumption and CO2 emission by at least 20 %. The battery banks will be recharged overnight by the shore-based electricity net.

Each ferry will measure 43.50 m in length and 12.20 m in width, the draught will measure 1.73 m. They will have a deadweight of 135 dwt and a tonnage of 135 gt.

Electrically powered fjord ferry

The ferries »Hallaig« and »Lochinvar« mentioned above are powered by diesel-electric drives plus power from battery banks. The electric power management system is designed and constructed by Imtech.

A fully electrically powered fjord ferry has been designed by Norwegian operator Norled, shipyard Fjellstrand and Siemens. The 80 m traject ferry can carry 120 cars as well as 360 passengers. From 2015 onwards it will serve the route between Lavik and Oppedal crossing the Sognefjord.

The ship’s batteries will be recharged in the breaks between crossings, a procedure which takes no more than ten minutes. The vessel currently serving this route uses on average 1,000 t of diesel oil a year and emits 570 metric tons (mt) of CO2 as well as 15 mt of NOx. The electrically powered ferry was developed for submission to a competition organized by Norway’s Ministry of Transport. As a reward for winning the competition, Norled has been granted the license to operate the route until 2025.

Klaus Nienaber