Unplanned thruster repairs and adjustments – both in dry dock and in situ – always lead to enormous costs, loss of productivity and decreased competitiveness. To combat this, CM Technologies (CMT) from Elmshorn/Germany, formerly known as Kittiwake, has developed a flexible thruster monitor that ensu[ds_preview]res that any damage, wear or necessary adjustments are identified immediately, allowing preventative action to be taken. This helps to avoid unpleasant surprises such as serious breakdowns.

According to CMT, the thruster monitor system is unique in that it provides real-time feedback on a whole range of oil and vibration parameters. The fully automated solution is ideal for both newbuildings and retrofit as it can be easily combined with any existing thruster and ship management systems.

The monitor serves as a reliable early-warning system that ensures cost-effective operations by extending the intervals between class surveys, thus reducing dry docking times and increasing the availability of ships and rigs.

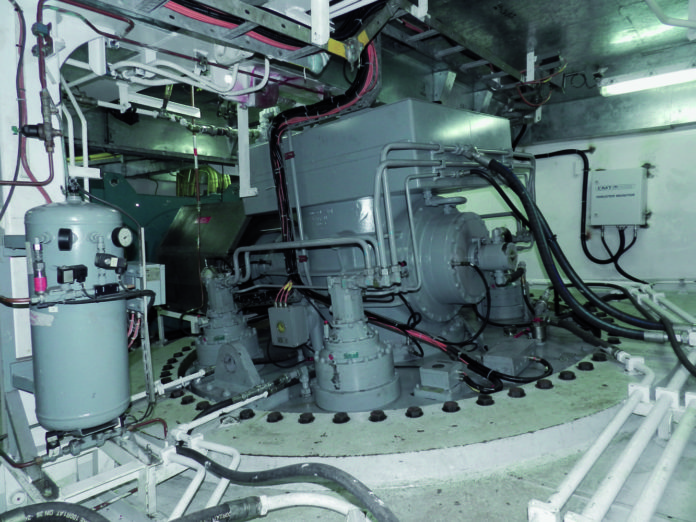

The CMT Thruster Monitor is designed for propulsion and positioning thrusters (tunnel and azimuth thrusters) and is aimed at ship operators and thruster manufacturers. It can be used for all brands and types of thrusters, and comprises a fully modular system providing tailor-made solutions for all individual requirements, CMT says.

The flexible system helps ship and rig operators to meet the condition based maintenance (CBM) requirements specified by classification societies, and allows proactive maintenance and operational decisions based on actual thruster condition. Furthermore, it provides on-screen trending of all parameters and can be easily remotely accessed at all times using a standard Internet connection.