As a full member of the IACS association, China Classification Society is the only specialised organisation in China to provide classification services

Based on national regulations and international conventions and rules, CCS provides technical rules and standards for ships, offshore inst[ds_preview]allations and related industrial products, and provides classification survey, verification, notarial inspection and certification services for our customers. These high quality services have won wide recognition among renowned shipowners around the world. CCS has now become one of the fastest developing classification societies and one of the classification societies with the best PSC performance. Meanwhile, CCS has made full use of its advantages in technology and resources to provide advanced, safe, green, applicable standards for the industry to help them to adapt themselves to the green shipping trend and to the new set of maritime technical standards. While CCS engages itself in promoting the upgrading of shipping, shipbuilding and supporting industry, it also increases its investment in technology research and development so as to provide innovative services to customers, and to safeguard the healthy, safe and green development of shipping and shipbuilding industry by providing advanced, safe, green and applicable standards.

I. Issuance of Rules for Green Ships, the first in the world

In 2011, CCS developed and issued the very first Rules for Green Ships in the world based on GBS methodology, and the Rules entered into force on 1 October 2012.

With detailed requirements and evaluation process, Rules for Green Ships offers class notations for Green Ships in three grades based on a comprehensive assessment of environmental protection, energy efficiency and working environment of a ship. Also, it assigns specific green technology notations such as energy-saving propeller, waste heat recovery, gas fuel, resistance reduction paint, shore power, wind energy, solar energy, fuel cell, etc. to encourage the use of green technology.

In order to promote inland river green technology, CCS has established framework for inland river green ship rules and standards based on analysis of the characteristics of inland river ships and shipping, and developed the following rules and guidance: The above rules and guidance have effectively promoted the application of green technology on inland river ships.

II. Issuance of rules for certification of energy efficiency management and relevant software system

In order to promote the use of energy efficiency technology and management measures, CCS issued to help companies to carry out energy efficiency management and certification, and guide the crew to use best practice so as to achieve the goal of energy saving and cost reduction. Ship Energy Efficiency Management System (EEOI) developed by CCS is an online platform for ship energy efficiency statistics and analysis. It has a unified data system, an index system with statistics and analysis functions, and is free for users. With the help of the system, shipowners can find out the results of ship energy efficiency management and compare it with other companies so as to get a clear picture of the change of energy efficiency, and can exercise real-time monitoring and analyse the results of measures taken. The system has been widely used in many large and medium-sized shipping companies and generated good economic and social benefits. According to statistics, ever since the implementation of systematic energy efficiency management in the year 2012, the energy consumption per unit of transport work of a large tanker company had dropped 23.4 % compared with the year 2011, saving 91,213 t of oil; the energy consumption per unit of transport work of a large container shipping company had decreased 12.73 % compared with the year 2011, saving 181,568 t of oil.

III. Research on high energy efficiency technology and -development of high energy efficiency ship types

To meet the demand for high energy efficiency ship types, CCS established an exclusive team to build a pool of high energy efficiency ship types featuring three main ship types: bulk carrier, oil tanker and container ship, to better serve shipowners before signing contract, and help them to achieve the goal of energy saving and emission reduction.

1. Research on high energy efficiency technology

Based on analysis and research results of high energy efficiency technology, CCS has built a technology information database of three main ship types, applicable to newbuildings and ship retrofitting, covering many technologies including optimisation on the bow/stern, energy saving appendages before/after propeller, and their onboard application effects, and provides optimisation solutions for existing ships of three main types, offering assistance and guidance to shipowners and ship designers for their benefits.

2. Ship energy consumption distribution and evaluation

Ship energy distribution and evaluation can be viewed as a »physical examination« of the ship’s energy consumption distribution. It detects weak links in energy saving, and provides effective solutions, which offers technical support to the use of green energy-saving technology onboard. After analysing the energy efficiency data of about 200 ships, CCS developed a set of software that can calculate and analyse ship energy consumption distribution, evaluate the level of energy efficiency, estimate energy saving potential of green technology. The above functions can meet the requirements of shipowners and shipping companies for energy consumption analysis.

3. Research and software development on optimum trim

Different trim will cause the change of the stern flow field, which affects the propeller propulsion efficiency. CCS has developed a set of software on optimum trim after conducting tank tests and CFD calculations. The software can present the relationship among trim, draught, speed and power of a ship under any conditions. To use the software, one only needs to type into computer information such as fuel detail, fore-and-aft draughts, speed etc. On a click of mouse, the automatic search of optimum trim will start, and the location of optimum trim at any draught will be located, and a comprehensive optimisation calculation report will be generated. In the report, one can find the following information: ship voyage, fuel, sailing conditions, proposed optimum trim and relevant estimation on energy-saving potentials, solutions for ballast water pre-adjustment, etc. A test run of the software was carried out on a container ship. Comparing with the usual squatting, it showed that with the help of this software, the main engine power was cut by 10 %, the daily consumption of fuel was reduced by 4 t, saving about 20,000 RMB on fuel cost.

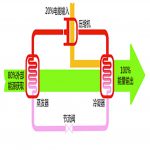

4. Use of heat pump onboard

The technology of heat pump is an energy-saving technology, it transfers heat from low temperature heat source to the high temperature one, so as to utilize the energy for cooling and heating of specific spaces. CCS developed heat pump products for luxury cruise, these products have gained economic profits and achieved the goal of energy saving and emission reduction. For example, a cruise will be able to save fuel up to 247.88 t per year, which is equivalent to 357 t of standard coal per year, and a 956.8 t reduction on CO2 emission per year with heat pump onboard.

5. Use of LNG, clean energy

CCS has established the technical standard system for LNG fueled ships. It includes: These rules and regulations have contributed to the breakthrough of key technology researches on LNG fuelled ships and LNG storage tank in China, and promoted the pilot work on LNG ship modifications, strengthened CCS’ leading role in technology research and contributed to a greener transportation with low carbon.