Are coatings as environmentally friendly as we would like to think or can more be done in order to make these systems better for the future, asks Samantha Fisk

Since the end of tributyltin (TBT) being used in paints and coatings the maritime world has endeavoured to use more[ds_preview] environmentally considerate alternatives. But, with the pressure on to also be efficient, can the best of both worlds coincide or will a balance need to be struck between the two?

Tributyltin comes under the umbrella term of organotin compounds and was found to have detrimental effects on ocean life. TBT was released into the marine environment by its leaching out of the paint applied to ships’ hulls. Not only did this affect sediments and organisms that came in direct contact, but also other marine species further up the food chain that consumed these organisms.

Due to this impact, the process for banning of TBT started in the 1980s and it became banned by the IMO through its International Convention on the Control of Harmful Anti-fouling Systems on Ships in 2008. Since the awareness of the effects of TBT, further regulations for TBT and other chemicals have also been adopted for paints globally.

However, Boud van Rompay, executive director, Hydrex believes that further development is needed both from manufacturers and from the IMO for modern paints and coatings to make them truly effective and environmentally friendly.

He opines that the latest solutions in environmental coatings focus too much on the use of silicones, which may present more issues when it comes to maintenance. »Silicones are extremely weak substances and there’s nothing that holds the matrix of the coating. It’s just too weak,« he says. He adds that with a silicone coating, extra care needs to be taken when cleaning a hull as it can become easily damaged.

Van Rompay believes that pollution is still a problem from organotin and biocide substances being used in coatings and further clarity is needed in regulating them. »Worldwide you will find antifouling particles. Massive amounts are going into the water,« he says. »Organotin is still being used as a catalyst in some paints that they use as an antifouling agent.« However, it would appear that the manufacturers are aware of this and organotins are still being used in today’s paints and coatings, but under strict regulation.

Victoria Frank, technical manager foul release, Akzonobel (International Paint), explains the use of organotins in International’s coatings: »To ensure that the paint film hardens correctly after it has been applied, one of our products contains very small quantities of an organotin catalyst. The catalyst is bound into the solid polymer matrix upon hardening and is not designed to leach into water. It works as a purely physical mechanism (a non-stick effect) and does not contain or rely on leaching of biocidal antifouling agents to work.«

However, for the manufacturers of these products, until suitable alternatives appear, there may be a need to use these substances in a small way, as Charlotte Rahbek, Group HSE & risk director, Hempel, explains: »At the current time, organotin catalysts are the only stable catalysts compatible with our resin technologies that we have identified so far. Current alternatives do not give us the technical performance we need for the paint film to be fit for purpose in terms of physical strength and application properties necessary to produce an effective coating.«

The use of biocides is also a concern for the marine environment, where some companies have opted to go biocide free in their product range, some still believe there is a use for them although at very reduced amount.

Peter Schoneveld, project leader eSHARK, PPG, highlights that: »The use of biocides in antifouling paints is managed, but if there was to be a total ban on biocides used in antifouling, then production of greenhouses gasses from ships would increase significantly, just at the point when reducing them has become critical. This is because underwater hulls would have no protection anymore against fouling growth. As a result, the resistance in water will increase, and hence the amount of fuel consumption might increase up to 50% – or more.«

Regulation clarity

Regulations have been set out in order to control substances that are used in paints and coatings for the maritime market. The IMO’s AFS convention sets out clear guidelines for the amount and usage of chemicals that are used to make paints and coatings. Along with this, there is a raft of EU and country-based regulations, as well as the Rotterdam Convention, which is a multilateral treaty that has been designed to promote shared responsibilities in relation to importation of hazardous chemicals.

Van Rompay says that further action is required from the IMO in regulating these substances to clarify the details. »The IMO needs to make a decision,« he adds about how catalysts are still being used.

Earlier in February, the IMO MEPC convened to discuss the topics involving antifouling systems. Under those topics discussed at the IMO was for new controls on the organotin substance cybutryne.

One of the topics highlighted in the proposal of MEPC 71/14 was: »4. Despite the ban (and close to effective phase-out) of harmful organotin compounds acting as anti-fouling systems, there is today a variety of different products, known as ›booster biocides‹ that are used in the composition of different self-polishing anti-fouling paints. Their impact on the marine/aquatic environment and ecological systems has been extensively studied with substantial evidence collected and conclusions derived as to their effects on non-target organisms. One of these active substances is cybutryne.«

In relation to cybutryne, Frank explains International’s action towards this substance: »The use of cybutryne as an antifouling biocide was reviewed as part of our company Priority substance program in 2017. After review, we decided not to use it in any new products and to stop using it from 1 January 2022 or from the date of a prohibition that may be agreed by the IMO, whichever is soonest.«

Future developments

Paint manufacturers are all still developing systems which will meet with the future demands of the industry, whether this is environmental or creating better efficiency for the ship.

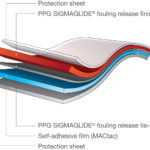

PPG is currently working on its eco-friendly Ship Hull foil system with fouling release and fuel saving properties through its eSHaRk project. The project is working to establish an automatic application process, which enables a self-adhesive, fouling release foil to be used on commercial ocean-going vessels. This process will allow shipowners and operators drag reduction capabilities of the PPG SIGMAGLIDE self-adhesive foil, the company noted.

The future for the shipowners caught in the middle of this looks to be a dividing issue, whether to look for the more environmentally friendly option to apply to their ships hulls or for the system that will meet with the requirements of the regulations, while still being affordable. Richard Towns, foul release segment manager, Akzonobel, concludes that: »There will be a balance between what people want [protecting the environment] and what is possible. Developments will need to be balanced by the IMO and the marine market and pushed by legislation.«

Samantha Fisk