If protective coatings would have the ability to recover from damages, the lifetime and durability could be extended significantly. Researchers at Fraunhofer IFAM are working on solutions

Self-healing means the ability of materials to recover the original function after damage without external measures or repairs. In[ds_preview] this sense other terms like »self-repairing«, »self-recovering« or »autonomic-repairing« could be used. In recent years extensive research was done on that topic following different technical routes. Fraunhofer IFAM is following two different approaches to self-healing coatings:

• Extrinsic self-healing by embedded microcapsules filled with healing agent

• Intrinsic self-healing by supramolecular interaction in the paint resin

Extrinsic self-healing

Within the last decade, microcapsules fabricated by using different microencapsulation techniques have found numerous fields of commercial application. Although being a highly interesting approach, the use of agent-filled nanoscaled containers and/or microcapsules for protective coatings is, concerning its technical readiness, far behind the examples mentioned above. No commercial product based on such technology was available recently in the field of coatings. However, having been first introduced by White et al. in 2001, the technology has proved its potential practical applicability in numerous academic publications.

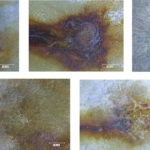

Healing agent-loaded microcapsules for wood coating purposes and for anti-corrosion systems designed for severe environments were studied in several multilateral projects at Fraunhofer IFAM. Microcapsules filled with a healing agent are incorporated into a paint film, that can be applied by rolling, brushing or spray-coating. If cracks occur microcapsules are ruptured and release the healing agent that seals the crack again. By using this approach even non-visible damages can be healed and crack growth being stopped. Hence, extended damage after mechanical impacts by blistering and cracking by water uptake of the substrate or the contact of metal with electrolyte, which initiates corrosion, can be avoided.

Concerning corrosion protection and parallel to the findings regarding applications on wood, the optimal microcapsule content is set around 10% regarding the coating’s solids. Thus, significant improvements of the corrosion-protection performance could be achieved and proven in salt-spray test and in a water ballast tank of a Mediterranean ferry respectively.

From the results obtained it was evident that the incorporation of microcapsules filled with healing agents can significantly improve the performance of protective coatings. The utilization of microcapsules in paints is beginning to become a commercially attractive option for paint manufacturers: recently the first commercial self-healing coating for wood protection reached the market. Thus it is likely that microcapsule based self-healing coatings for other applications like e.g. corrosion protection will follow soon.

Intrinsic self-healing

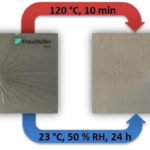

Whereas extrinsic self-healing requires the presence of self-healing agents, intrinsic processes are based on supramolecular networks. After microcracks form, the supramolecular network is able to self-heal through reversible non-covalent bonds. This concept describes a supramolecular polymeric system that interacts through weak physical bonds like hydrogen bonds.

Conclusions

The investigations have shown that self-healing mechanisms have a high potential for the development of coating systems with improved durability. This applies for protective coatings and decorative coatings.

Since the extrinsic approach is already commercialized for one particular application (wood protection), there are still other possible applications like heavy-duty corrosion protection, where research projects have shown that the idea would work. Commercial products in these fields are still to be developed. The maturity of the intrinsic approach is currently much lower, but the phenomenon of the self-healing mechanism is thoroughly investigated and understood. Further research into the development of paint resins that could be implemented in commercial paint formulations is necessary to exploit this promising technology.

The results presented were obtained in several funded projects: The European Union’s Seventh Framework Programme for Research, Technological Development, and Demonstration funded the project »ThroughLife«.

The German Federal Ministry of Economic Affairs and Energy funded the project »SelfRepCoat« which was coordinated by the Research Society for Pigments and Coatings (FPL) and financially funded via AiF.

Volkmar Stenzel, Claus Schreiner, Anastassija Wittmer