Reduction of pollutants in diesel engines

Diesel engines are powerful, reliable and efficient. Mobile commercial vehicles such as trucks, buses, forklifts, excavators, ships, and stationary combined heat and power stations for example are usually powered with diesel aggregates. Exhaust[ds_preview] after-treatment measures that significantly reduce pollutants such as soot and nitrogen oxide emissions, in particular, through an optimised inner-engine combustion as well as in the exhaust, have contributed in this regard.

However the statutory regulations (EU, EPA, IMO, UIC, etc.) for further reduction of NOx gases and particles, can only be achieved through additional emission reduction systems, uncoupled from engine operation. In this case, low-emission engines no longer conflict with general fuel savings.

However the statutory regulations (EU, EPA, IMO, UIC, etc.) for further reduction of NOx gases and particles, can only be achieved through additional emission reduction systems, uncoupled from engine operation. In this case, low-emission engines no longer conflict with general fuel savings.

Components, such as valves, sensors, or complete dosing modules in emission reduction systems with SCR technology, require a higher level of material resistance chemically and thermally, and a high level of physical leak tightness. Consequently, electromagnetic shut-off and control valves from Bürkert use specially encapsulated coils manufactured in-house.

Modular and efficient platform system

Bürkert engineers integrate these coils in dosing units of different capacity classes in a manner appropriate for the application. This guarantees an optimised, costefficient overall size, in addition to a significantly reduced variety of interfaces. Dosing modules increase the integrity and reduce installation and test complexity.

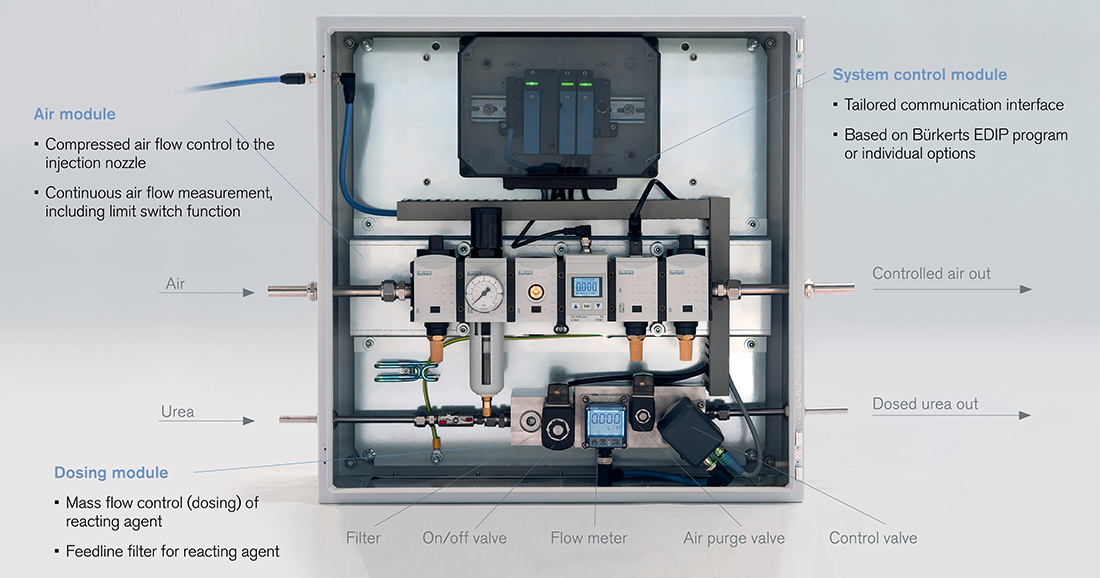

Compact dosing modules generally contain components such as a solenoid control valve, an on/off valve, a temperature sensor, a pressure sensor, a heating element and are constructed using on-demand plastics technology. Non-road applications use dosing units mounted in control cabinets. The number of components is larger, including for example flow meters. While these control cabinet solutions are custom tailored, they are based on a platform concept. This allows fast and efficient adaptation of systems to different performance classes.

Adding value with Bürkert systems in exhaust treatment applications

Bürkert’s broad product portfolio is the basis for SCR dosing units from a single source. All valve and sensor specific core components are qualified for the area of application and are time-proven. Product diversity, experience with SCR system technology and the platform concept keep development times short.

Having all the necessary in-house production technologies such as metalworking, plastics technology and control cabinet construction boosts efficiency in the development and production process. All this allows for quick testing and compliance with statutory limit values.

Your advantages:

Application-proven platform

- Superior design

- Professional advice and support

Compact and service friendly design

- Fully validated system with necessary documentation from a single source

- Easy commissioning, reduced maintenance effort

Quick and efficient customisation possible

- Prequalified, complete sub-system for faster access to market

- Reduced engineering effort