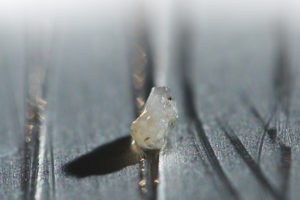

Today’s cat fines challenges demand a smarter approach to the fuel line

For ships sailing with residual fuels, cat fines are a clear and present danger. Centrifugal separators remain the most important line of defence, but they become even more effective as part of an optimized whole. For this reason, many vessels have taken a more comprehensive fuel line approach to boost both protection and energy efficiency.

Cat fines continue to cost ship owners and operators thousands of dollars in repairs and lost business. Statistics reveal that 40% of today’s 500 cSt fuel has a cat fine level of 40 ppm, and that 50% of all operators cannot remove enough cat fines to reach engine manufacturer specifications.

When new sulphur regulations take effect in 2020, the situation may grow even worse, as low-sulphur fuels often contain even more cat fines. Responsive fuel treatment – with technology that adjusts automatically to oil composition and engine load – has become more important for ensuring safe vessel performance in this changing environment.

Finding a complete cat fine solution

Today’s challenges demand a comprehensive strategy that comprises all aspects of fuel treatment, including separation and fuel conditioning, as well as the fuel feed. It can therefore be important to work with a reliable partner who can provide not just the necessary equipment, but also a deep understanding of issues related to the entire fuel line.

Alfa Laval is one supplier with a long history of expertise in this area. Their S separators with Alcap technology have led the way in responsive fuel treatment for cat fine protection. With further innovations like FlowSync, today’s Alfa Laval adaptive fuel line offers the market’s most complete approach.

Alfa Laval is one supplier with a long history of expertise in this area. Their S separators with Alcap technology have led the way in responsive fuel treatment for cat fine protection. With further innovations like FlowSync, today’s Alfa Laval adaptive fuel line offers the market’s most complete approach.

FlowSync is an automatic separator feed pump control system that synchronizes the feed with the engine’s actual fuel consumption. By seeing that only the necessary amount of fuel is pumped, it creates better conditions for the separator, allowing more fuel retention time in the separator bowl. This leads to even better cat fine removal, as well as energy savings within the separator.

Expertise for protection and savings at SMM

The Alfa Laval adaptive fuel line also includes solutions to detect elevated risk or loss of separation efficiency, enable safe management of multiple fuels and recover waste fuel for reuse. Taken together, these technologies offer more than just peace of mind. They also create potential annual savings of as much as USD 1,000,000.

During this year’s SMM exhibition (4–7 September in Hamburg, Germany), Alfa Laval experts will be on hand to discuss the challenges of new low-sulphur fuels and present the latest efficient solutions for the marine industry. Visitors interested in learning more about the comprehensive approach to cat fine protection can visit Alfa Laval at Hall A1, Stand A1.226. To book a meeting with an expert in advance, visit http://www.alfalaval.com/smm2018