The Japanese carrier goes for the ultimate target: reducing ship emissions to zero. The NYK vision is bold, a collection of technologies already develop but never used in that way before. It also includes new concepts to get a vessel that demands 70% less energy

To achieve its greenhouse gas reduction targets and decarbonization, NYK has reviewed the technical advances conceived for its previous future[ds_preview] concept ship »NYK Super Eco Ship 2030«, a concept based on a 350 m container vessel. Together with MTI, the maritime R&D arm of NYK, and Elomatic, an engineering and consulting company based in Finland, NYK took advantage of advancements in hull remodelling, hull weight reduction, energy conservation, and digitalization to newly design an emission-free future concept ship.

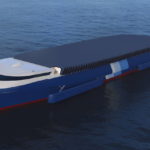

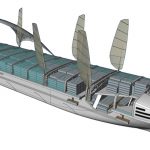

The new »NYK Super Eco Ship 2050« has been crafted as a pure 200m car and truck carrier (PCTC). The power needed to operate the ship has been cut by 70% by remodelling the hull to decrease water friction, reducing the weight of the hull, introducing fuel cells for electric propulsion, and relying on other highly efficient propulsion devices. Instead of fossil fuels, power for the ship would come from solar energy and hydrogen produced from renewable energy sources, all of which would lead to a reduction of CO2 by 100% and thus result in a zero-emission vessel.

The 2050 design features a lightweight hull with minimal resistance, leading to 34% less energy being needed. An improved propulsion efficiency cuts energy demand by 6%, while solar power (-5%), fuel cells (-18%), improved electricity demand (-8%), improved electrical power distribution (-1%) and waste heat recovery (3%) will reduce the energy demand even further.

The weight of the hull is reduced through a dynamic, mathematical design combined with topology optimization. In addition, utilization of new lightweight materials for the structure will become common, NYK believes. Weight reduction will allow vessel-hull optimization to focus on minimizing resistance. The ship’s stability is ensured using pontoons. In normal condition, the pontoons are stored above seawater level to minimize resistance. But in the event of high seas or abnormal conditions, they will drop to the water to provide additional stability. Computer-controlled devices like gyro stabilizers will be installed on the vessel bottom to provide active stability.

Conventional propellers are replaced by flapping foils that mimic the movement of dolphins to deliver greater efficiency than screw-type propellers. The design also utilizes an air-lubrication system. During sea navigation, air bubbles are delivered to the vessel bottom to reduce frictional resistance between the hull and the water. During port stays, automatic hull cleaning robots will clean the dirty hull to reduce resistance that could negatively affect vessel efficiency. These robots will also collect all debris to prevent pollution of ecological systems at port.

Fuel cell and renewable energy

The vessel is powered by hydrogen fuel cells (SOFC), in which the hydrogen is produced by renewable energy sources. According to NYK, the design has a power production efficiency of 69% through waste heat recovery. The hydrogen tank capacity of 1,900m3 ensures a 21-day endurance. The storage of liquefied hydrogen on board the vessel will be expensive and require significant space, so fully utilizing power produced on board is essential. Therefore, the designers propose to use solar power allowing for an energy conversion efficiency of 45%. About 9,000 m2 of solar panels will cover 15% of the total energy demand.

Holistic Digital Twins of each vessel will enable access to shorebased expertise for the crew on board. Several scenarios can be evaluated to optimize planned and corrective maintenance to minimize accidents and troubles on board. Thanks to advanced weather and performance optimization, route planning is no longer a ship-level activity. It is done at the port and at fleet level, which enables just-in-time arrival throughout the supply chain. Simultaneous ship-to-berth and ship-to-ship cargo work will minimize port stay hours. Shorter port stays will allow for slower sea navigation and result in energy savings. Thanks to improvement of shore facilities, automatic mooring and berthing will be possible to minimize port stay hours. Shore power is also supplied to the vessel.

In April 2009, NYK released the initial exploratory design for its Super Eco Ship 2030. This concept already included the utilization of lightweight materilas, optimized hull shape and other progressive technologies with potential of being realized by 2030. The 2030 design featured LNG-based fuel cells, solar cells and wind power, all of which will lead to a reduction of CO2 by 69% per container carried.

Felix Selzer