The charge is building up: The progress of the »Color Hybrid« ship construction in spring 2019 has been steady, and the plug-in hybrid vessel is getting prepared to enter service in June with a lot of innovative technology on board

For a long time, Ulstein Verft’s yard number 311, the »Color Hybrid«, has been hiding in the dock hall. Now[ds_preview] it has been painted and launched. The delivery is scheduled for May 2019 to enter service in June, so the waiting for the world’s largest plug-in hybrid vessel will be over soon. The environmentally sound ship will be servicing the 38nm route between Sandefjord – Strømstad (crossing time 2,5 hours) from summer 2019. Ulstein won the contract in competition with several other yards. In Februabry 2017, Color Line and Ulstein Verft signed the contract on construction of the 30,000 GT ship designed by Fosen Yard.

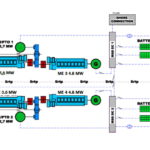

The new RoPax cruiseferry uses new solutions to reduce noise and emissions. The vessel features a diesel-electric plug-in hybrid concept with PTO/PTI allowing for hybrid propulsion using both direct-drive and electric. Siemens batteries installed in four battery rooms in the machinery area deliver a combined capacity of 4.7 MWh.

At vessel speeds up to 12kn, the 5 MWh battery package weighing almost 70t is going to allow for 60 minutes of fully electric operation. In normal operation the vessel’s top speed is 17kn. The battery system was delivered by Siemens, who manufactured the batteries at its new production facility in Trondheim. Siemens is well-known for being a key supplier for ferry operator Scandlines’ hybrid ferry »Berlin« (196m, 1,600 lane meters), which is in service in the Baltic since 2016 and uses batteries with a combined capacity of 4.5 MWh. The energy management system for this vessel and her sister ship »Copenhagen« already came from Siemens, while the batteries came from Corvus Energy.

The batteries are recharged via a power cable with »green« electricity from shore facilities or, as a secondary alternative, recharged on board by the ship’s generators. With shore power provided in Sandefjord, all Norwegian ports on Color Line’s network will have shore power facilities. The ship will have full battery power into and out of the fjord to Sandefjord inner harbour. It will therefore not give emissions of harmful greenhouse gases or nitrogen and sulphur compounds in this area.

The ship is equipped with four Rolls-Royce Bergen B33:45L in-line diesel engines of which two are B:33:45L6 (six cylinders, 3,600 kW) and two are B33:45L8 (eight cylinders, 4,800 kW). The four engines were delivered in March 2018, the contract came with an option to provide engines for a second vessel. The »Color Hybrid’s« engine and energy layout also features a waste-heat recovery system.

Norwegian company Brunvoll supplied the propulsion package including controllable pitch propellers and tunnel thrusters, gearboxes, rudders and steering gear. Besides the two CP-propellers, Brunvoll delivered two fixed-pitch propeller tunnel thrusters and one rim-driven, permanent magnet tunnel thruster as well as control systems for propulsion, positioning and manoeuvring.

A »local« project

Steel cutting started in July 2017, in April 2018 Crist shipyard in Gdynia, Poland, began to assemble the 14 blocks of the ship’s hull. After the hull was completed it was then towed to Ulsteinvik in November 2018 for outfitting.

According to Ulstein, »Color Hybrid« is a good example of the interaction in the maritime cluster. Ulstein Verft has contracted the subsuppliers to this project, of which about 70% are local. Ulstein Power & Control delivered its ULSTEIN COM communication system, other key suppliers include Kongsberg for navigation and communication equipment, switchboards come from Clean Marine Switchboards, UPS (Uninterruptible Power Supply) is from Anda Olsen. Alfa Laval delivered fuel oil separators, lube oil separators and oil heating, Allweiler is responsible for pumps, valves came from Ahlsell.

Mare Safety/Viking supplied life rafts, while Palfinger delivered the lifeboats for »Color Hybrid«. Teknotherm was contracted for HVAC equipment and fridge/freezer technology, R og M for accommodation and galley, Jets for vacuum toilets and Norac for wet units. While Libra supplied external doors, interior doors came from Baggerød. Glamox supplied lighting fixtures, Elpro supplied decorative lighting, cash registers came from Checkmark. Jotun is listed as paint supplier.

Capacity of »Bohus« doubled

The ship is classed by DNV GL as 1A, Ferry A, Clean, NAUT(OC), TMON, COMF(C(2)V(2)), ICE(1B), MCDK, LCS(DC), BIS, F(MC), Battery(Power), VIBR, Recyclable, BWM(T)

At 160m legnth, 27,1m width and a draft of 6,0m it will have almost double the capacity of the ferry »Bohus«, which is going to be phased out when the new ferry will be put into operation in summer 2019. »Bohus« was built in 1971 as »Prinsessan Desiree« for Sessan Linjen (now Stena Line). The new ship will provide significantly increased capacity on the route between Norway and Sweden. The new vessel can take on 2,000 passengers, 100 crew and 500 cars. The building cost for the vessel amounted to 120mill. €, 80% of funding was covered by DNB Bank and the Norwegian Export Credit Guarantee Agency.

»Color Hybrid« was built according to Norwegian flag requirements and registered in the Norwegian Ordinary Ship Register (NOR). Color Line is currently the only company in the international passenger and freight traffic to and from Norway with ships registered in the Norwegian Ship Register and with Norwegian headquarters.

»Color Hybrid« will be servicing Sandefjord – Strömstad from summer 2019. Even before the ship has been built, she has earned her first award. At the opening ceremony of the Nor-Shipping exhibition in 2017, the ship was appointed the winner of the Next Generation Ship Award. With a focus on innovation, the award honours the most promising design on ships that will be launched in the coming decade. According to the jury, the vessel demonstrates the innovation and ambition that are pushing the maritime industry forward to a greener, more profitable and more sustainable future.