The digital transformation of our industry is a fluid process. Progress in information technology (IT) has always been incremental and continuous. The »Compit« conference is a traditional occasion to determine the current position and course of the maritime digital transformation. An exclusive preview by organizer Volker Bertram

The renowned Conference on Computer and IT Applications in the Maritime Industries (Compit) takes place in May in Pontignano, Italy[ds_preview]. During the conference programme, some key topics will be discussed from various perspectives.

4-dimensional digital twins

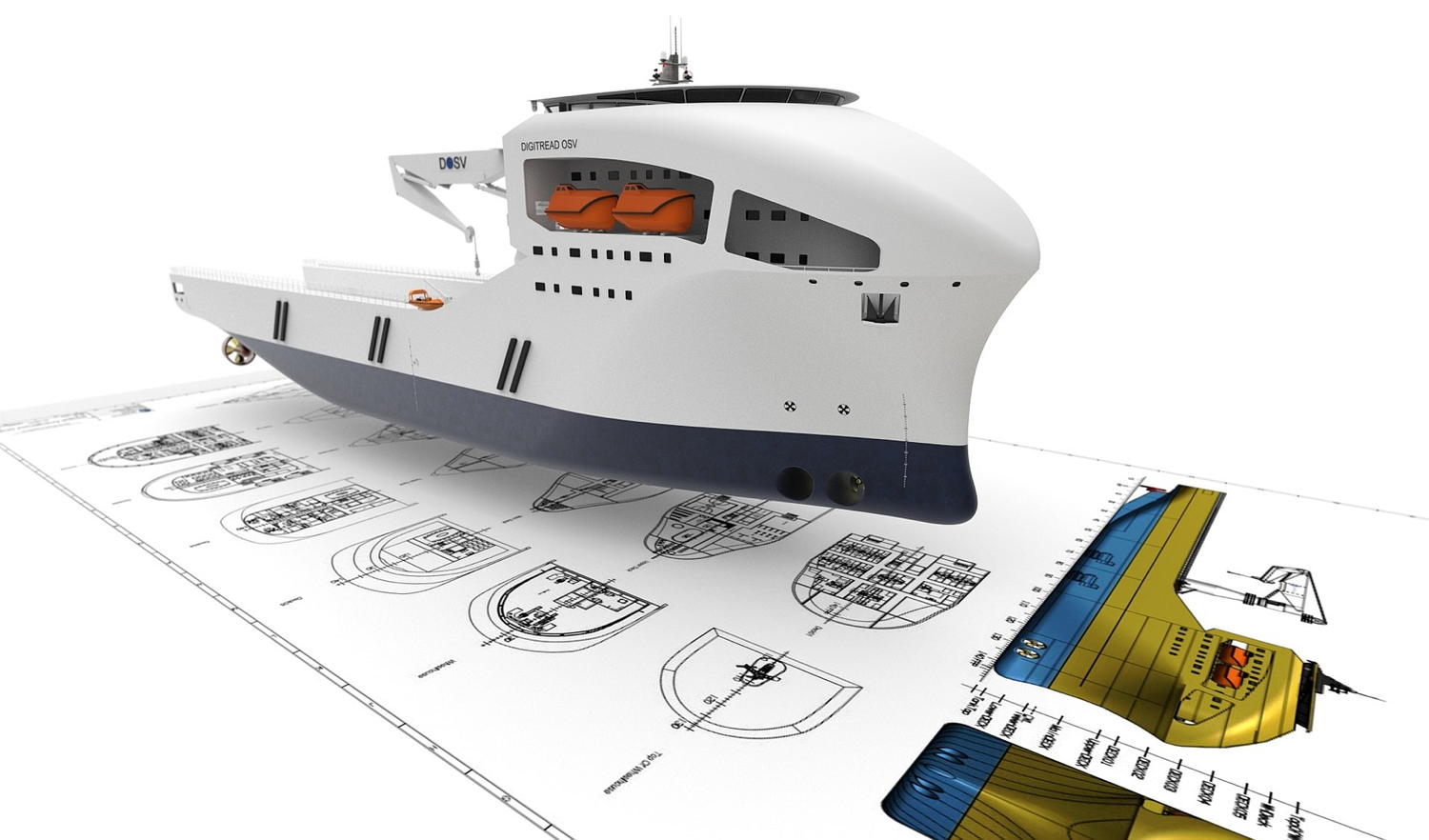

The Digital Twin is a recurring theme. Digital Twin information must be managed from the start in initial design, explain Perez & Munoz from Sener. Classification societies have embraced the Digital Twin concept in plan approval, with 3d models replacing the traditional large-size 2d drawings, making the exchange between shipyard and classification society more efficient, as illustrated by Kil et al. from Korean Register.

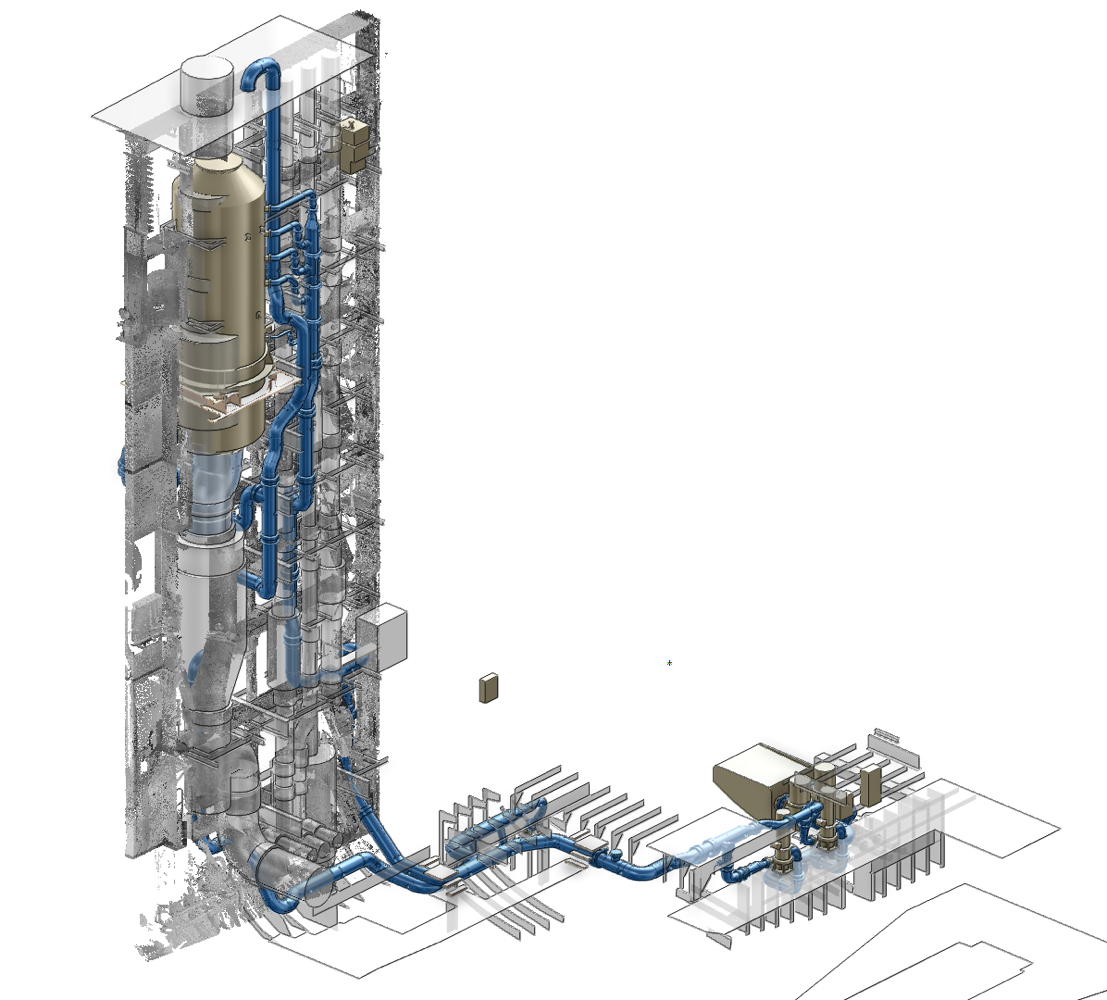

For the existing fleet in service, Digital Twins often have to be created from scratch. »For older ships without appropriate digital representation of the as-built status, this can be a major headache. 3D Laser Scanning has been found to be a viable solution for such cases. Initially motivated for retrofits, the geometrical digital twin created by advanced 3D laser scanning has proved to be very versatile, being used also e.g. for preventive maintenance or further redesign of engine rooms,« explains Marius Blom, CEO of BLOM Maritime. More than an interesting side note, Blom quotes up to 30% savings on material cost and up to 35% on manhours in retrofit projects.

And Digital Twins are not limited to machines or ships. Bekker et al. from Stellenbosch University describe their vision of a human digital twin, the Mariner 4.0: »A seafarer [is] considered […] with an associated human digital twin that is a virtual representation of the unique individual that dynamically reflects [his] physiological status and life style over time.« A specific case illustrates how we may use human digital twins: human comfort monitoring and management.

MASS hysteria or MASS market?

MASS stands for Maritime Autonomous Surface Ships and is the official term used by IMO for its regulatory developments for increasingly autonomous ships. What was still a rather exotic vision in the year 2000 is turning into reality and it comes as no surprise that Compit 2020 discusses MASS technology from various angles.

Orvieto from ZF Marine Propulsion Systems looks at parallels and challenges compared to the automotive industry: »With marine transportation playing such a vital role in the world today, why is it that the marine industry lags behind the automotive when it comes to [autonomous driving] development and application? What can be done to close the gap, and what unique challenges might need to be overcome along the way?« But having a closer look, there are more parallels than differences between the automotive industry and shipping: liability is a major concern; we will see partially autonomous vehicles much more than fully autonomous (unmanned) ships. Market mechanisms, legal procedures and disparate technological developments point in this direction.

Navigation, especially collision avoidance, has been a focus of MASS aficionados in the past decade and still is, as elaborated by Berge & Daehlen from Sintef. But now the focus starts to widen towards the issue of reliable machinery needed in fully or largely autonomous ships. Extended autonomy will also require extended periods without human maintenance and repair for the machinery, as pointed out by Rahav (TotemPlus) and Abaei & Hekkenberg (TU Delft). And, of course, Artificial Intelligence plays a key role in this.

Human vs Artificial Intelligence

However, we humans seem to get more intelligent, when it comes to Artificial Intelligence. It is encouraging to see several papers taking a hype-free stance comparing human capabilities to A.I.

For example, Eriksen (University of Southern Denmark) raises an interesting point in his discussion of whether on-board human operators are liabilities or assets: »Many claim that eliminating the presence of an on-board crew will eliminate accidents attributed to errors caused by humans. [However,] while a large portion of accidents are commonly attributed to human error, these statistics do not include failures prevented and/or mitigated by human operators before they develop into an accident.«

Bekker (Stellenbosch University) & Ligthelm (Ship2Shore Marine Connection) look at a polar research vessel operating during its voyages in extremely harsh conditions. Does the experienced ship master pick up situations where the ship is at its limits, and the sensors and A.I. don’t, or vice versa? The answer is likely to be the time-honoured compromise: sometimes the machine beats us, sometimes we beat the machine. Best combine the respective strengths. This is something that Van der Broek et al. (University of Rotterdam) look into in »Meaningful Human Control in Autonomous Shipping – An Overview«. The future will lie in combining machine diligence and multi-tasking capabilities with human common sense and experience. It already starts at a smaller scale.

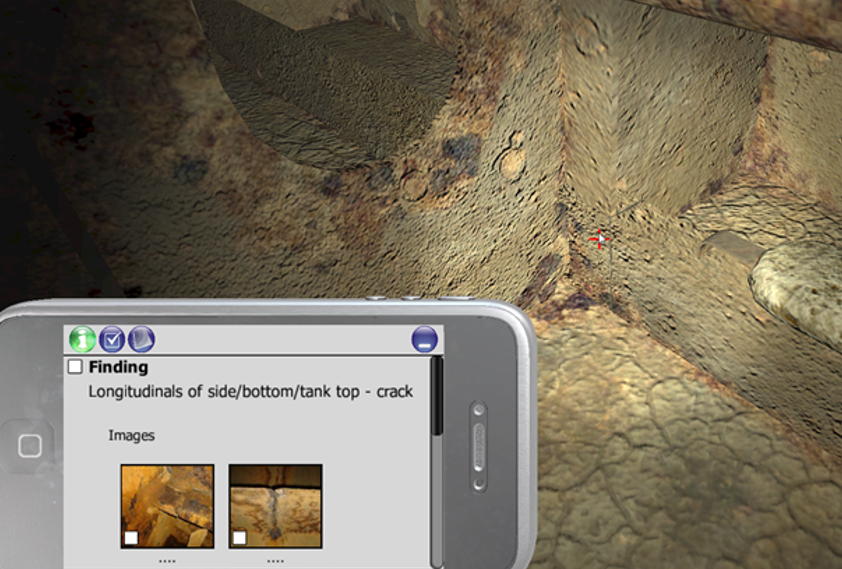

Stensrud from DNV GL looks at drone-based ship inspection of ships, where A.I. screens thousands of images to short-list those which are likely to show cracks, but the final assessment lies with a human surveyor. Or Caprace et al. of COPPE with a similar application for underwater inspections using AUVs.

Training Mariner 4.0

If the future holds an ever-closer symbiosis of man and machine – and resistance against the cyborg world seems to be futile – this will affect training which evolves in parallel, adapting to digital requirements and exploiting digital opportunities.

We said good-bye to the concept of training or studying once for a lifetime of professional work. The trend is towards ever shorter times from training to application. In the extreme, it is just-in-time training on the spot, more aptly termed instruction.

Using Augmented Reality techniques, instructions or images are overlaid, guiding crew or workers in what to do. Procee et al. (NHL) and Nordby & Gernez (AHO) look into applications for AR-enhanced ship bridges. Friedewald et al. from TU Hamburg describe an Augmented Reality system for installation of equipment, including the display of maintenance instructions, the feedback of setting values and the documentation of the work including storage in a digital twin. Industry users estimate time savings of up to 75% per maintenance case.

Van der Ende et al. (NHL) compare the effectiveness of training switching from conventional 2d displays in an engine room simulator to Virtual Reality 3d displays. Bertram et al. (DNV GL) describe SuSi (Survey Simulator), a Virtual Reality training tool for ship surveys.

In summary, the maritime IT world does not face disruption or revolutionary change, but a fast transition. And the fast movers and future Mariners 4.0 will gather in May in Tuscany. The COMPIT conference promises yet again to be a highlight in this year’s calendar for anyone interested in how the digital transformation is changing our maritime industries.

Volker Bertram