»Technologies for Future Ships and Future Shipping« is the theme of the 12th HIPER conference. Advanced thinkers from research and industry meet in Cortona, Italy, in October, to look into the crystal ball for our future.

The larger themes will come as no surprise to the industry: the future will be green(er) and smart(er[ds_preview]). But let’s have a closer look …

Green(er) shipping

The 2020 »sulphur cap« is old hat. Even the 2030 IMO carbon footprint goals fail to excite me. We can reach them with the engineering technology and commonly discussed ideas. But IMO’s 2050 zero carbon shipping goals will require us thinking out of the box. They will require ingenuity, entrepreneurship, and boldly challenging my generation’s common wisdom.

Looking at Hiper program, I am for once mildly optimistic. The practical dreamers and creative engineers have come forward, surprising even me with some of the ideas, most of them proven and matured to at least prototype stage. The small and medium enterprises see the challenges as opportunities, and one can only wish them Godspeed.

»If one does not know to which port one is sailing, no wind is favorable,« said Seneca. But since the goal is clear, the wind seems to be favorable for sustainable propulsion, most notably wind assisted propulsion. Uwe Hollenbach of DNV GL sees »Wind Assisted Propulsion Systems as Key to Ultra Energy Efficient Ships«, and he is supported by two sessions with variations on the theme.

Kites, rigid sails, or Flettner rotors? Only time and evolution will tell. Much depends on vendor prices, operational profiles and design constraints. But one thing seems to be clear: If you combine your green sails with a smart routing software, you may double your savings. Green is the new smart; smart is the new green.

Outside the box

Thinking out of the box? The Dutch companies Conoship and Econowind do exactly that. Their sail system is deployed from a container and can be folded away when the winds are not favorable.

Sustainable propulsion is more than just wind propulsion systems. Becker Marine Systems joins forces with Wallenius Marine in a project combining various elements; sails are the most visible and prominent ones, but inside hydrogen is driving the machinery and generating the electricity modern shipping needs.

Hydrogen or ammonia – what will be the future carbon-free fuel? Looking at Hiper, one is tempting to bet on hydrogen. Roy Campe of ship operator CMB shares experience with Hydrogen-Powered Zero-Emission Ship Projects in Belgium, for tugs and inland shipping. And new fuels come with new machinery technologies. Gone will be diesel engines, noise and vibrations.

The future is electric, fuel cells and batteries. The trend is towards more ships adopting it, e.g. expedition cruise ships, and towards larger units, as demonstrated in the German MultiSchIBZ project presented by ThyssenKrupp Marine Systems. Maritime fuel cells offer higher efficiency than diesel engines, but have long start-up times and allow only slow load changes. Subsequently they are usually combined with batteries, where metal-air battery technology enables significantly longer zero emission sailing ranges and lower total cost of ownership.

However, reaching the goal of zero emission shipping is not just about technical solutions, as Teus van Beek (Wärtsilä) points out. It requires a change in mindset and business models. Financing hurdles have to be overcome, for example by pay-as-you-use schemes. Fortunately, such schemes are already evolving and introduced by some maritime suppliers.

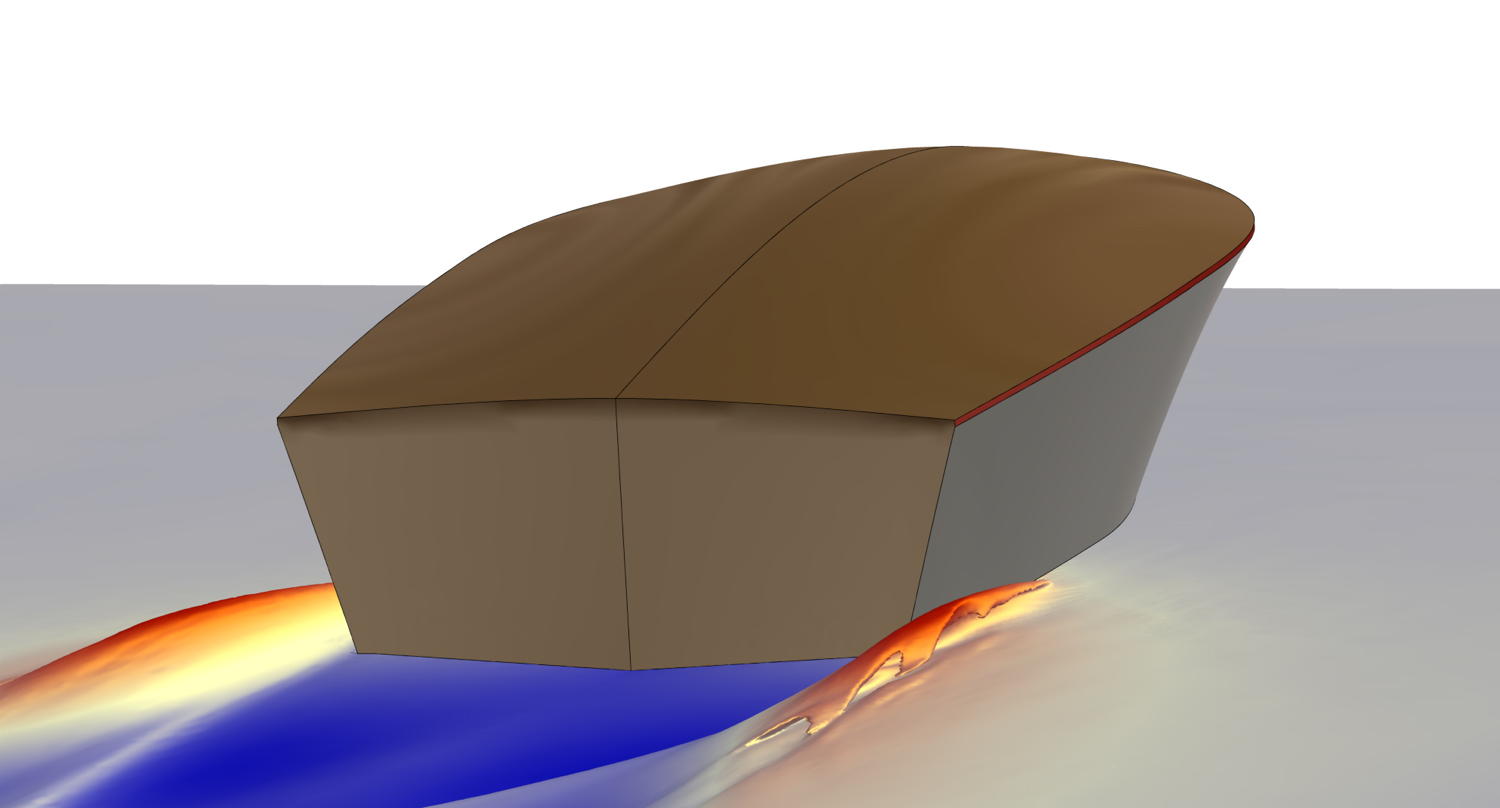

But how will future zero emission ships be designed? In principle, not very differently from how we design ships today. The designs are more innovative than the design process. However, current tools are adapted and as the designs are subject to different constraints, e.g. stability for wind propulsion, the resulting projects are unique. At Hiper, we see databases adjusted for fuel cell machinery, CFD applied to ships with Flettner rotors, and optimization of electric-propulsion vessels.

Green, smooth, smart

The limelight in the shipping industry is on zero emissions. But there is another sustainable shipping topic that draws a lot of attention now in shipping circles: hull management. Part of the explanation of why this topic is en vogue is that IMO biofouling guidelines are due for review, but there is more to it. The demand for proactive in-water cleaning has risen due to energy efficiency targets over the past 5 years, but in the same period most ports have clamped down on in-water cleaning due to concerns about invasive aquatic species and accelerated biocide release. Where there is a problem, there is an opportunity. A new world of biocide-free antifouling solutions is waiting in the wings, covered in two session »Future antifouling solutions«.

You may have heard of the silent revolution, using ultrasonic transducers, as presented by Jan Kelling of Hasytec. The technology is mature and a good idea for niche areas which are critical for biofouling management.

The unseen revolution

But have you heard of using ultraviolet light? The unseen revolution. Industrial heavyweight Philipps and paint manufacturer AkzoNobel have joined forces to develop a novel fouling prevention solution, based on the generation of UVC light by LEDs embedded in a transparent layer.

And there is no shortage of clever ideas on »passive« solutions. Fraunhofer institute and Hamburg Ship Model Basin have taken inspiration from Mother Nature. Salvinia, a floating fern, traps air with microscopic hairs. The »Aircoat« technology mimics this, providing passive air lubrication. Another idea is using microscopic (or nanoscopic) surface structures to make adhesion of fouling organism difficult and mild cleaning easy. And while you’re at it, why not use latest 3d printing technology for these nano-coatings? Prototype developments from Sweden and Italy are presented.

Smart(er) shipping

While the »green« contributions certainly fascinate, they cannot overshadow the »smart« developments. Emilio Campana of CNR give and overview of converging ICT technologies, from the Internet of Things to Artificial Intelligence, from everywhere computing to Digital Twins.

The unmanned or autonomous ship is like a pervasive vision on the horizon, a great illustration of how a multitude of technologies cooperate and cross-fertilize, but also a great example of how the vision is often decades ahead of reality. A key role is played by Artificial Intelligence, »Maritime Industries’ Next Useful Idiot«. Japan’s »On Future Strategy and Technology Roadmap of Maritime Industry« puts high priority on it, Spain’s well-known CAD vendor Sener reinvents its portfolio building on IBM’s A.I. software, and ABB challenges the conservative skepticism: Machine Learning can surpass your traditional expertise and yesterday’s rules – »Believe it or not«. Charismatic business leader and long-term aficionado Giampiero Soncini (IB Marine) not only believes in A.I., but that Covid-19 may bring an acceleration of related autonomous technology and marine robotics.

Think tank for modern Leonardos

The challenges for future shipping seem sometimes unsurmountable, but as the Chinese proverb says: A journey of a thousand miles begins with a single step. And it is encouraging to see that many steps in the right direction are taken.

If there is one message to take from the HIPER 2020 program, it is this: Forget the prophecies of doom! The industry is reinventing itself and its innovative drive is impressive. Interdisciplinary expertise and innovative thinking meet this year in Tuscany, a suitable location for the »think tank« of the modern-day Leonardos.

Volker Bertram