VAFT OPT is an innovative design approach to generate fuel savings of more than 5 % for newbuildings. The technology has been applied to optimize a container vessel (at SVA Vienna) and a bulk carrier (HSVA) for the purpose of validating the technology. Classes and flag states joined tests recently executed at HSVA as impartial witnesses for bulk[ds_preview]er tests

Maritime stakeholders face tough challenges in complying with future IMO regulations and natural demand coming from climate change and energy transformation. During this »most innovative SMM ever«, decarbonisation, fuel changes and fuel savings are amongst the hottest topics.

The traditionally very slowly adapting shipbuilding industry has to deal with challenges related to new designs from hull to engines. Stakeholders try to develop their know-how and improvements rather than utilising 3rd parties’ technologies. Their main concerns are intellectual property rights and the cost of ship production, which seem to be more critical than the unutilised benefits for ship owners or charterers paying the bill.

While industry stakeholders focus a.o. on utilisation of different types of future fuels to comply with CII/EEDI-3 requirements, we, LR-Shipdesign AG, deliver previously unidentified solutions for ship hull design improvements with a unique patented hydromechanical and hydrodynamical innovation: AFT OPT.

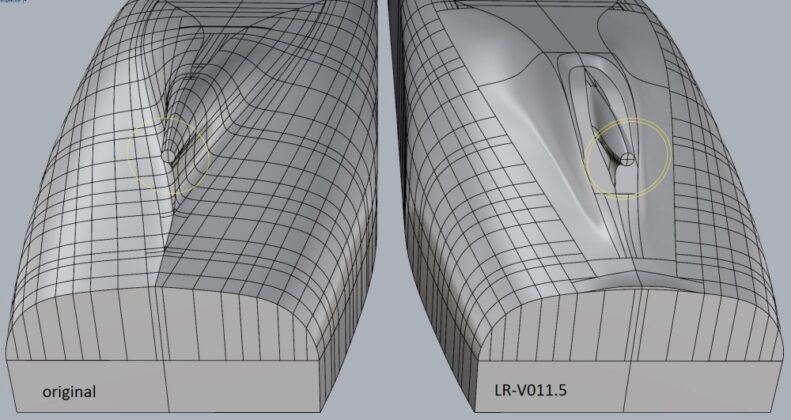

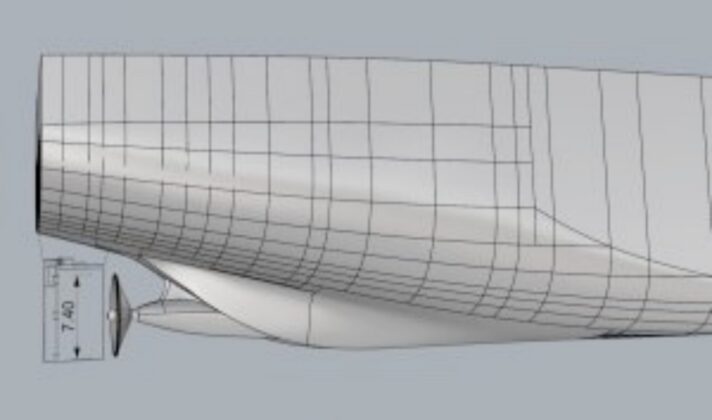

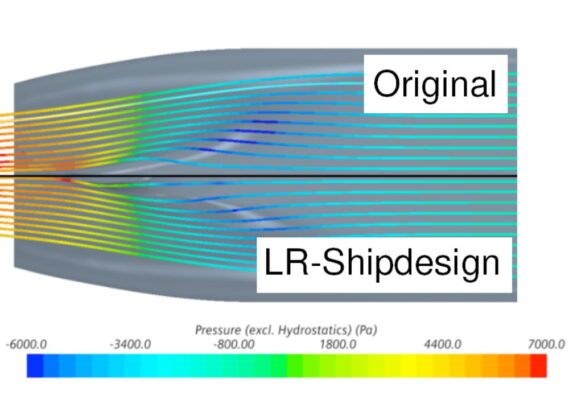

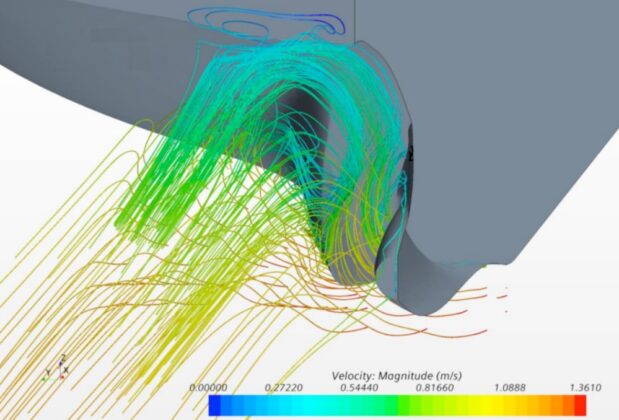

AFT OPT is nothing less than a unique detailed analysis of the flow of water cells underneath a ship’s hull – from the bow to the rudder. The core of AFT OPT is a slightly modified area in the hull bottom aft section to accelerate the flow of water (»water jet«) in parallel to the main hull line. The effect: more water is delivered to the propeller disc with a better distribution to fill the whole disc area. Consequently, both a propeller and a twisted rudder, designed to deal with the vortex flow and increase propulsion, contribute to much more efficient energy utilisation.

All this can be implemented in ship newbuildings with minimal engineering effort compared to the shipbuilding cost.

Induced by the special AFT OPT form and input edges of the ship’s bottom semi-circular form, the applied pressure is reduced, and the water flow is accelerated due to the indentation. The energy losses are reduced, and the flow pattern long the edge lines (shoulder), stern, and trailing whirl are optimised.

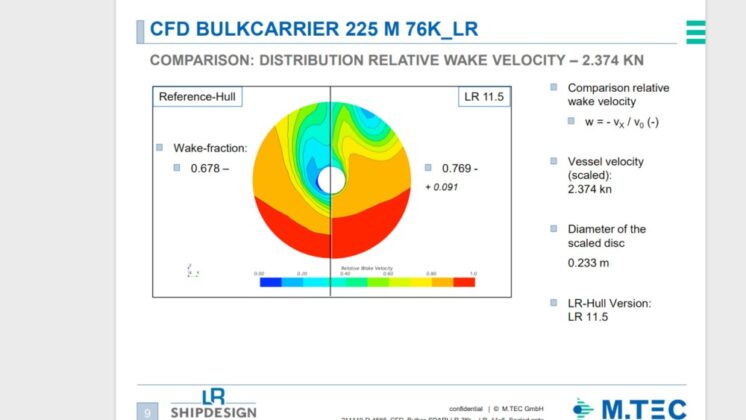

This system essentially improves the water flow to the propeller and rudder. The propeller gains more pressure, especially in the 12.00 hrs position, and further savings are generated by an adaption of the transmission and/or propulsion.

Historically, the analysis of fuselage flow, the flow of air around the wings of aircrafts, led to the question at LR-Ship-design, whether a specific new approach can be made to improve the flow of water underneath the keel.

AFT OPT today consists of its CFD and calculation tools. Results have been validated at SVA Vienna (3,500 TEU container vessel) and HSVA for a Panamax bulk carrier. International partners delivered their latest designs as input information to LR-Shipdesign. The aim was to improve the vessels’ efficiency without changing the cargo capacity. The engine manufacturer has approved minor modifications regarding the main engine room.

In both cases, the hull‘s resistance with-out attachments was improved by more than 3–4 % in full scale (4–5 % in model scale). The overall result for the bulk car-rier reached a 9.7 % improvement in full scale with propeller and rudder attached. These results were achieved in June 2022 at HSVA; based on these tests, further slight improvements have been identified.

The competitive advantages of the Patented Lindinger Hull are:

- A Fuel reduction of more than 5 %, up to 10 % in regular operation

- No additional maintenance expenses during operation

- Enhanced efficiency of the propeller by reducing both – the thrust deduction fraction and slip

- Lower vibration and lower noise development due to the propulsion unit

- Functional for all semi-glider and displacement hulls

Conclusion

Ships are only sustainable future assets when combining all new requirements of builder and user. Shipowners should not be shy to use their purchasing power to combine more economical shipbuilding know-how with their ship‘s operational requirements. The cost for new merchant vessels is relatively low compared with the OPEX during a ship’s lifetime.

Authors: Roland Lindinger | LR-Shipdesign (Zug, Switzerland) and Volkmar Wasmansdorff | Movena (Bremen, Germany)

Acknowledgements

We are grateful to our industry partners for providing their hull lines and support for developing holistic solutions for propeller design and main engine setup (MAN), and rudder design (Loewe Marine). We would also like to thank the managers of SVA Vienna and HSVA for their scientific support and all participating classification societies and flag states for the validation of AFT OPT technology.