Almost 90 % of the commodities traded worldwide are transported by ship, and that figure is steadily rising. Ballast water tanks give vessels stability and the necessary draught required for costeffective operations. Ballast tanks are filled with sea water, fresh water and a mixture of the two, pumped in from the world‘s oceans and discharged again as required.

Every year, around 12 billion tons of ballast water are used, water that contains countless »stowaways«. Every time a ship[ds_preview] takes in ballast water, it also involuntarily takes in masses of tiny aquatic organisms and distributes these on the world‘s waterways. Although a large proportion of the microorganisms, such as bacteria and viruses, do not survive being transferred in the ballast tanks, a sufficiently large number of organisms are released when the ballast tanks are emptied. Once these invasive species (fish, small invertebrates, worms, bacteria, viruses and other microbes) settle in their new habitat, they can potentially cause considerable ecological and economic damage. In extreme cases, they can become a hazard for humans.

Ocean Protection System OPS: simple, efficient, costeffective The ballast water is treated as it enters the ship‘s tanks. The challenge here is to ensure that all organisms, and particularly the very small ones, are rendered completely unviable. Mahle Industriefiltration‘s NFV ballast water system OPS uses a combined method which is based on three precisely coordinated system phases: the first and second phases filter extremely fine solids and marine life and the third phase uses low-pressure UV radiation to kill or deactivate even the tiniest microorganisms. The Ocean Protection System OPS makes ballast water management simple, fast and very cost-effective. The low-maintenance technology needs only a very small space to deliver excellent results. Furthermore the system works environmental friendly without any chemicals, it can be used with the existing ballast water pumps and the power consumption is very low.

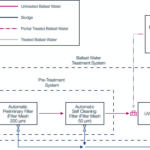

Overview of the system

The OPS is a three-stage ballast water treatment system. The system works as an in-line system during uptake and discharge of ballast water. During uptake the first step of treatment is a prefiltration for separating particles larger than 200 m, followed by a second filtration for separating particles larger than 50 m. With this pre-treatment most parts of sediments are removed from the ballast water. The sludge from the self-cleaning process will be discharged at the same place where it was taken on board. The uptake treatment finishes by disinfection via ultraviolet light. Figure 1 shows the principle operations (flow chart). During discharge only the UV disinfection is in operation, while the other stages are bypassed.

Functionality of the Ocean Protection System OPS The ballasting process starts and the medium flows axially against the first filter stage. Filtration takes place from the inside to the outside of the filter element and the cleaned medium leaves the filter through the radially-mounted outlet flange. When the filter element reaches a defined differential pressure (the filter element is packed with solids) an axially slidable disc moves up and down during the reversible flow by the help of a pneumatic cylinder within the filter element. All operating conditions are monitored by the control unit. After passing the first filter stage the medium flows into the second filter stage: an automatic self-cleaning screen filter designed specifically for ballast water treatment application. The filter is offering a high level of compliance within the IMO’s D-2 standard as well as an efficient solution for filtering sea water containing large quantities of dirt. The filtration process creates differential pressure across the screen which rises as the »cake« enlarges, until a predetermined value is reached (normally 0.5 bar) to activate the flushing process. In cases of low operating pressures and generated suction forces not reaching the required minimum level, a small suction pump is added to the flush line to assist the cleaning process. This is a reliable and inexpensive addition to the system, enabling the filter to operate under extremely low pressures of only 1.2 bar. This low operating pressure is crucial, in particular for retrofit’s, because the low operating pressure meets the parameters of existing ballast water pumps and therefore save costs and potential reconstruction.

Further advantages are:

• due to anti-corrosion coating, the operating time of the filter is extended

• the system is a fully automatical self-cleaning system, which efficiently handles heavy dirt load in raw water

• filtered water is continuously supplied during the self-cleaning process

• the second filter stage generates very low costs per cubic meter of filtered water

After the fine filtration of the medium it becomes treated by ultraviolet light. The ultraviolet light is a natural component of the electromagnetic spectrum. One of the most effective disinfecting wavelength and the one most often used for disinfection is at 254 nm. The ultraviolet light necessary for disinfection is generated in low pressure-high output amalgam lamps. Each lamp is housed and protected against water pressure by a special quartz sleeve. A watertight quartz tube surrounds each lamp. The ballast water to be disinfected is turbulently conducted through the reactor chamber. The gas plasma generated in the lamp emits light with a primary wave length of 253.7 nm. This intensive ultraviolet light reaches organisms in the water and impacts directly on their DNA.

By changing the DNA the cell division of the organism is interrupted – it can no longer reproduce itself. With this technology it is possible to kill or inactivate harmful microorganisms in water, without adding chemicals, without harmful side effects, inexpensively, highly efficient, and reliable.

UV disinfection is an entirely physical process. Microorganisms such as plankton, viruses, yeast that are exposed to the effective UV radiation are inactivated within seconds. UV disinfection of wastewater has become an accepted alternative to chemical methods of disinfection for secondary and tertiary quality wastewater.

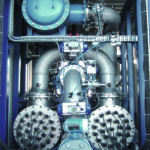

Reportedly there are over 1,000 UV systems are in operation throughout North America, Europe, and Asia. The many advantages over chlorination result in a continued increase in interest and use of ultraviolet light as a disinfectant. The disinfection by UV requires no chemicals and therefore causes neither corrosion problems, reaction tanks or secondary pumps, risk of overdosage, need of special storage or handling, nor environmental problems. The de-ballasted water remains alive and enables further organisms to life in the water. Furthermore it retains its natural flavour and smell without any by-products that might endanger health. In addition to that, UV reactors require minimum operation costs, due to low power consumption and little maintenance by maximum operating safety (Figure 2).

The treated ballast water becomes stored in the ballast tanks during the journey. The de-ballasting process bypasses the two filter stages and the medium flows prior to discharge only through the UV reactors to assure absolute accordance to the IMO regulations.

Due to its modular design, the NFV ballast water treatment system OPS offers a wide array of options and configurations: it can be operated as a compact, container-housed unit or adapted to the vessel‘s design and layout

Current situation

Land-based test as part of G8 IMO approval, which was made at NIOZ (NL) and conducted on behalf of the German administration (BSH), was successfully finished in 2009. Shipboard test is in process on a container vessel at the moment. Mahle anticipates the marketability of its OPS which includes all necessary approvals for 2010.

The OPS is a mechanical-physical energy efficient system, which is working without any chemicals. Mahle Industriefiltration GmbH is a partner at the Interreg IVB North Sea Region Programme »Ballast Water Opportunity«.