In ship repair and conversion, it comes down to having a ship back »en route« as soon as possible and for as long as possible. That is the reason for working with a specialised yard ready to offer reliability both in speed and quality of work. Shipowners choose a yard that is flexible, service-oriented, competitively priced and that shows its talents for improvisation when needed. In other words, a yard that is willing to go the »extra yard« to meet getting the ship repaired and converted as required. Shipdock with its yards in Amsterdam and Harlingen exactly offers that kind of partnership. With a dedicated technical staff, strong project management and first-class ship repair and conversion facilities, a ship is given all the required priority and professional care. A flexible organisation and efficient working methods ensures it to leave the dock or berth with the shortest possible notice to return to service.

Shipbuilding and repair activities in the northern area of Amsterdam root back to the 1920s. Since then its names and[ds_preview] proprietors have changed several times. Originally founded as the Netherlands Dock Company (NDM) as repair yard it merged with the Netherlands Shipbuilding Company (NDSM) after the WW2 where new ships had been built. As from the end of 1960s it became a Verolme Company which later on merged with Rijn Schelde, by then named RSV (Rijn Schelde Verolme). In the 1970s, when that company collapsed, the repair activities were taken over by Amsterdam Drydock Company (ADM) which moved to the location where it still exists today. After ADM, too, had gone bankrupt in 1985 the receiver decided still to continue its activities – now as Amsterdam Naval Services (ANS), which modernized the famous Dutch navy vessel »de Ruyter« and converted it into the Peruvian cruiser »Almirante Grau«.

This project became the foundation of Shipdock Amsterdam in 1987, formed by DCG Holding, who also had interest in another smaller shipyard in Amsterdam, Oranjewerf, securing ship repairs to survive. Since that time various maintenance dry- dockings with repairs / conversions have been carried out on drill ships, pipe laying vessels, offshore diving support vessels, anchor handing tugs and general supply vessels for international customers.

The IMCA Group had taken over Shipdock Amsterdam in 1999 and the owners changed its name to »Amsterdam Shiprepair« in 2003. Also this company went bankrupt in the middle of 2005. Volharding Shipyards, Braspenning Coatings and the former management decided to revive ship repair activities in Amsterdam – now under its previous name »Shipdock«. Ship repair at Volharding Shipyards in Harlingen also became part of the company under the name Shipdock Harlingen B.V. Today the shipyards are still located at these two premises.

Owing to problems the Amsterdam part of the company was re-established in 2005 and is now focusing on international shiprepairs and conversions. In 2006 the yard Harlingen joined the group for regional shiprepairs and conversions together with Niron, a steel workshop and machining company in Amsterdam. Thus the Shipdock Holding nowadays actually consists of three companies:

• Shipdock B.V., Amsterdam

• Shipdock Harlingen B.V., Harlingen

• Niron Staal Amsterdam B.V., steel constructions and machining at the Amsterdam yard

Shipdock is a flat and open organisation with the emphasis to render best and tailor made services to its customers and is aiming for a long term relationship with shipowners. Its main markets are in the Netherlands, Belgium, the UK, Norway, Germany, Japan and Hong Kong.

Key customers of the Amsterdam facilities among others are within the dredging and offshore industry. Ships which are being repaired and / or converted here are offshore vessels, jack up platforms, car carriers, fishing factory vessels and product carriers. In Harlingen local ferries, offshore crafts, container feeders and fishing vessels are being handled.

The company is constantly investing in improvements of its facilities and equipment to ensure a safe and most effective working environment. Dedicated project teams, up to date view on costs for each project, invoice ready before departure, fast and cost effective steel repairs, own machine shop on site, many subcontractor services on site (like scaffolding, painting, electrical workshop, carpenter/insulation workshop).

Recent projects in Amsterdam

The yard in Amsterdam offers full service on site with a flexible organisation. Customers are being treated like partners and profit from the efficient working methods of a dedicated technical staff.

Leg extension of a jack-up platform

In Amsterdam a leg extension of the jack-up platform »Sea Jack« has been performed within a 28 days period. The platform was docked on a raised dock bed with a height of 4.0 m to allow removal of spud cans and lower section of legs. The legs were cut and the four spud cans with a weight of 80 t each and with attached section of leg were transported from dry dock to steel workshop. Four prefabricated leg sections were fitted and welded to the spud cans, these were then returned to drywdock, positioned with self propelled platform trailers and welded to the legs, extending each leg by about 1.4 m.

Other works were included like:

• overhaul of sheave blocks for lifting of platform,

• fabrication and installation of lifting beams in engine / hydraulic rooms

• installation of additional generator set, including piping, exhaust etc.

Conversion / renewal of refrigeration and fish processing on »Carolien«

A complete removal of all existing equipment such as compressors, coolers, froster tables etc was carried out with extensive steelwork to create new spaces to accommodate the new installations. New decks were installed, existing decks blasted and coated. New equipment with all kinds of outfitting was installed.

Recent projects in Harlingen

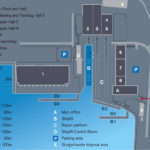

The shipyard in Harlingen has a direct connection to the open sea and is equipped with a ship lift and adjacent platform which secures efficient docking facilities. Apart from attractive harbour dues, pilot agency fees and its highly skilled personnel the yard also has a conversion hall, a grit blasting and painting hall.

Renewal of a cargo tank on »Star Curacao«

The double bottom and side tank section was cut out and transported with hydraulic trolleys. The imploded tank was lowered and removed. A new stainless tank with a weight of 28 t was positioned underneath the vessel and hoisted into place. Thereafter the double bottom and side tank were transported, lifted into position and welded. The work was finished by connecting all cargo lines to the cargo tank.

GF