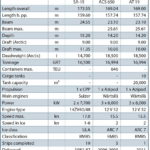

The Arctic tanker »Enisey« delivered by Nordic Yards carries the legendary tradition of Russian ice-strengthened cargo ships into a new era: It can move through ice of up to 1.50 m.

Since 8 October 2011 the newly built »Enisey« has been operating between the North Russian ports of Dudinka, along Siberian[ds_preview] river Jenisey near Norilsk and Murmansk, on peninsula Kola. This Arctic tanker type »Nordic AT 19« (AT = Arctic Tanker; 19 = 19,000 tdw) has to master a distance of about 1,500 NM through often ice-covered waters. At the end of September, Nordic Yards Wismar delivered their hull no. 505 to her owners, the Russian mining group Norilsk Nickel, which is one of the ten largest companies in the country.

The ship is designed in accordance with the climatic conditions of the operating territory for temperatures down to minus 50° C and consequently according to the rules of Russian Maritime Register of Shipping Arctic ice class ARC 7. It is planned to operate the tanker in Arctic waters all twelve months of the year.

In harsh ice conditions the vessel operates astern at a speed of 2 kn and can break through permanent thick ice of up to 1.50 m. In open waters the vessel reaches a speed of 15.3 kn sailing with the bow forward. This double-acting operation mode is called DAS (Double-Acting Ship) and is originally patented by Masa-Yards Arctic Research Centre (MARC), part of Aker Yards and former Kvaerner Masa-Yards Inc (See HANSA 5/2006, p. 21.).

Navigating in Arctic conditions

Maintaining year-round traffic on the Northern Sea Route, especially between Murmansk and Dudinka, which are the most important ports in the Russian Arctic region (See HANSA 5/2006, p. 18.), had always been a high priority for the former Soviet Union and still has for Russia today due to the economic exploitation of the vast natural resources of minerals as well as oil and gas of these Northern regions. The Northern Sea Route is also an important link between Europe and Asia as it significantly reduces the transit time in comparison to the route through the Suez Canal.

However, while the Soviet Union had a large fleet of ice-strengthened cargo ships, the year-round operation along the Northern Sea Route had primarily relied on the large nuclear-powered icebreakers. In the late 1970s Sudoimport, the Soviet Union’s trade organisation with a monopoly for the foreign trade on ships, requested for tenders for the design and construction of 20,000 tdw Arctic cargo ships according to specifications laid down by the Ministry of the Merchant Marine of the Soviet Union (MORFLOT).

At that time leading Finnish shipbuilders Wärtsilä and Valmet both developed designs that met the requirements for the new class of Arctic cargo vessels capable of year-round operation on the Northern Sea Route. Wärtsilä was using its knowledge and experience gained from building more than half of the world’s icebreaker fleet in service at that time and Valmet from several types of ice-strengthened cargo ships which the yard had built in the 1960s and 1970s.

»SA-15« class of ice-breaking freighters

Finally an initial order was placed for nine ships in July 1980, six with Wärtsilä and three with Valmet. Wärtsilä’s contract was the largest single contract realized by a Finnish industrial company in those days. In the following year three more ships were ordered with Wärtsilä and two with Valmet, resulting in a total order of 14 ships.

While the ships became known as »Norilsk« class, following the name of the first unit, they were also referred to be their project name which denotes a sub-arctic (SA) 15,000 tdw (15) cargo ship, known as »SA-15« type. All together 19 »SA-15« class ships were delivered by the two yards in 1982 to 1987 and by June 2011 nine were still in service.

The largest initial operator was Murmansk Shipping Company (MSCO) which owned and operated a fleet of ten »SA-15« class cargo ships in the Western part of the Soviet Arctic. It was followed by two companies operating in the Eastern regions, Far East Shipping Company (FESCO) with seven and Sakhalin Shipping Company with two vessels. Later MSCO transferred three units to its affiliate, NB Shipping, and the ships were transferred from Russian to Cypriot register.

Despite decades of service in some of the harshest operating conditions on earth no »SA-15« class freighter has been lost. However, even the newest ships became almost 25 years old and were approaching the end of their economic life. Increasing operating costs of the old vessels with relatively large crews will eventually force the shipping companies to retire currently still operating old »SA-15« class ships and look for replacements, especially for the more demanding Arctic routes.

From »SA-15« to »ACS 650« and »AT 19« class

In 2006 to 2011 the mining and metal company MMC Norilsk Nickel designed and contracted a series of up to now six 14,500 tdw double acting ships with former Aker Yards in Finland (today STX Finland) and Germany (today Nordic Yards). On 11 April 2006 Aker Yards delivered hull no. 505, Arctic container vessel »Norilskiy Nickel«, from their Helsinki shipyard (today Archtech Helsinki Shipyard). Two thirds of this hull were constructed in Germany (hull no. 418 from Aker Warnow Werft Operation), whereas the technically more sophisticated aft part was built in Finland and completed to the finished container ship.

In July 2006, after first sea trials had been completed successfully with the prototype »Norilskiy Nickel«, Norilsk Nickel ordered further four container vessels of the same type with Aker Yards, which decided to build these units completely at their yards in Germany.

In spring 2008 it became known that Norwegian Aker Yards Group was on the way to sell their shipbuilding activities in Ukraine and Germany to Russian owners, later known as Wadan Yards. This group ran the German yards only less than two years till insolvency in summer 2009.

Another Russian investor came into picture and runs the two yards under the name of Nordic Yards now. He completed most of the existing contracts, especially the two giant Stena Super Ferries »Stena Hollandica/Britannica« (See HANSA 8/2010, p. 40.). He also managed to fix at least the sixth ice-breaking ship project with Norilsk Nickel which required an Arctic tanker similar in design to the formerly delivered five Arctic container ships of the type »Aker ACS 650« (ACS = Arctic container ship; 650 = 650 TEU). This tanker was delivered recently by Nordic Yards (the name of the yard since summer 2009) ex Wadan Yards (2008–2009) ex Aker Germany (until spring 2008) and is now consequently known as type »Nordic AT 19«.

Modernized Arctic container ships »ACS 650«

Originally, the Arctic container vessels of type »ACS 650« had no loading cranes although the vessels’ construction was already strengthened for the installation of two cranes. During the service of the first units of this type it was realized that more containers and especially reefer-containers than originally planned were transported, even though the main cargo consisted of bulk and semi-finished metal-products on the westbound route Dudinka–Murmansk. The fourth unit of the series delivered in 2008 (hull no. 161) had been fitted with two electro-hydraulic loading cranes (Crane type CBW 45(34)/28(37) from Liebherr having SWL 45/34 t lifting capacity with 34/37 m outreach.).

This year, the prototype of »ACS 650«, the »Norilskiy Nickel«, had been in service for five years and came to Nordic Yards for inspection and classification works. These works included retrofitting of two similar loading cranes, two additional provision cranes and a shelter deck. A new harbour diesel generator and more reefer sockets for containers were installed. The vessel’s underwater surface has been sandblasted and completely preserved again. Various supplementary maintenance and repair works were performed during the stay at the yard. By end of July 2011 the ship returned to its hard duties on the Dudinka-Murmansk route.

Arctic tanker »Nordic AT 19«

The new tanker »Enisey« is a specialized double-acting product tanker with ten cargo tanks and of high Arctic category. The vessel was designed and constructed under the survey of the Russian Maritime Register of Shipping (RS) (With the notation RS KM (*) ARC7 [1] AUT2-ICS EPP Anti-Ice VCS IGS-IG ECO BWM CSR Oil tanker (ESP) (ARC7 at d <= 9.00 m).). It is capable to move through ice fields of up to 1.50 m thickness with its stern forward in a speed of up to 2 kn. With its characteristic icebreaker-bow forward the vessel can ram by pure power and weight through thickest ridges in the traditional way of icebreaking. This changing mode from astern to forward sailing is made possible by the 360° rotating azimuth propeller drive called Azipod. In open waters the tanker is sailing with the bow forward under a speed of up to 15.5 kn. The shape of the hull and all main equipment is identical to that of the Arctic container vessels type »ACS 650« (See in detail HANSA 9/2008, p. 86–94.).

Klaus Nienaber