Due to the »economy of scale« philosophy, ships have constantly grown in size. Thus, passenger

handling on- and off board has become more complex – and so have the challenges for cruise lines, destinations and ports. How long will this trend persist?

In today’s tourism and cruise environment people often talk about »post-panmax vessels« or »mega cruise ships« labeled through several[ds_preview] trends and the race about the largest cruise vessel by the two market leaders. But what does a cruise ship classify as a yacht, boutique ship or mega liner? Where are the limits? Expert views on this topic are quite divergent, as there are no generic definitions or classifications of cruise liners. This article will try to approach the topic of increasing ship sizes, its causes, implications and challenges.

Cruise industry overview in a nutshell

Presently, worldwide there are about 360 ocean cruise vessels (with 60 passengers and more) offering cruises to the public. In sum, these ocean cruise vessels offer a capacity of almost 440,000 beds [1] (on a lower berth basis) to the passengers. The ocean cruise industry is dominated by four big players. These big four are Carnival Corporation & plc, Royal Caribbean Cruises Ltd., Genting Hongkong / Star Cruises and MSC Cruises, many of them incorporating various other brands. More than 100 cruise lines [2] are offering cruises to potential cruise passengers. For this year approximately 19 million cruise passengers will have cruised worldwide.

Both the European Cruise Council (ECC) and the Cruise Lines International Association (CLIA) publish economic impact studies annually. They visualize the importance and influence of industries to certain countries. CLIA strongly focuses on the North American cruise market, which is still the leading market in the world, with its implications on the economy of the United States. The ECC focus is set on Europe, the second largest cruise market. According to the economic impact studies on the year 2010, both markets generated each more than 300,000 jobs. Within the United States (US) the cruise industry had a total economic impact of 37,85 bn $ (ca. 26.34 bn €) [3]. Total economic impact includes direct spending like expenditures by cruise lines, their passengers and crew as well as indirect spending like expenditures of cruise line suppliers. According to the ECC, total economic impact by the cruise industry on Europe amounted to 35.2 bn € [4]. Comparing these two figures, more total output is generated in Europe than in the US. Although approximately 7 % more jobs are produced in the US, Europe wins again with 14.5 bn € [5] direct spending compared to 18 bn $ (ca. 12.5 bn €) direct spending in the US [5]. Reasons for this may be quite diverse, but given the fact that the cruise shipbuilding industry is mostly located in Europe, these numbers and differences might be interpretable.

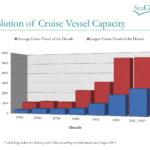

Vessel capacity increased steadily over the past decades

Analyzing cruise vessels from todays’ operating cruise fleet on a lower berth basis (LB), cruise vessels built in the 1950s show an average capacity of 336 passengers. The largest still operating cruise vessel built in that decade is »The Emerald«, which can accommodate 990 Passengers. The largest cruise vessels delivered in the 1950s, 1960s and 1970s differ only 134 passengers in capacity. The same range, with a difference of 170 passengers, applies to the average cruise vessel capacity in those three decades. With the ongoing evolution of technology and with the beginning of cruising on a broader level, the 1980s show a first big jump in the category of largest capacity. Although average capacity did not increase much in the 1980s compared to prior decades, the capacity of the largest ship increased by more than 1,000 lower berths from the 1970s to the 1980s. Today’s »Sovereign«, currently operating for Pullmantur but launched 1988 as »Sovereign of the Seas« for Royal Caribbean International, is the largest vessel of the 1980s which is still operating today, with a capacity of 2,276 passengers. Hence, this cruise vessel is able to carry twice the capacity compared to the largest still operating vessel of the mentioned decades before, which is the »Oceanic«, built in 1965.

Looking at the category »average capacity« of cruise vessels, the 1990s show the start of the building boom of cruise vessels with an increase of 81 % compared to the 1980s. In the 2000s the average capacity climbed more than 800 lower berths compared to the 1990s, and correspondingly 1,300 beds on average compared to the 1980s. A cruise vessel delivered in the 1990s fits twice into the average cruise vessels delivered in the 2010s and on order until 2016, whereas more than four average cruise vessels from the 1980 could be fitted according to the capacity. This lineup shows the trend of increasing ocean cruise vessel capacity.

More than 100 cruise vessels built in the 1990s and 116 cruise vessels built in the 2000s sail in todays’ cruise fleet, compared to 56 from the 1980s and 18 from the 1960s. If maintained properly and upgraded frequently at least every 10 to 15 years, cruise vessels can easily reach an age of 50, before used for a different purpose or scrapped. It is necessary to mention, that not only larger vessels, but also small and medium-sized vessels were permanently ordered in the past, but with a gap from 2004 to 2010 [6] resulting from the »economy of scale« philosophy these days. This is the reason why cruise products are as diverse and as different as they are today.

The trend of increasing cruise vessel capacity and correspondingly cruise ship size can be explained by the utilization of economy of scale effects. The operation of a cruise vessel is a very fix cost intensive business. Therefore, cruise lines wish to spread those fix costs, which mainly include costs associated with the production and operation of the vessel, across a large amount of beds. If done so, the production costs per bed decrease and respectively the cruise bed can either be sold for a lower price, which again is a driver for further growth and an additional reason for progressive consolidation and intensification of competition within the cruise market, or generates a larger margin.

Next to direct economic effects the cruise lines’ drive to build and operate the »largest cruise ship in the world« is a marketing tool as well as a prestigious competition. Especially the two market leading cruise lines have been competing and battling for this title for decades. The title of the biggest ship has always drawn attention of the press and media to the equivalent ships and cruise lines. From today’s perspective the competitive race about this title is decided in favor of Royal Caribbean International with the vessels »Oasis of the Seas« launched in 2009 and the »Allure of the Seas« launched in 2010 with each facing a lower berth capacity of 5,400 passengers [7]. Or did Carnival simply let Royal go for the biggest? However, all cruise vessels presently on order are smaller in capacity than those two Royal Caribbean ships. Momentarily, there are no official plans from competitive cruise lines to build ships larger than the above mentioned Oasis class vessels.

The reason for not building larger vessels might root in two facts. Firstly, port infrastructure is not (yet) corresponding to the requirements of such big ships. This topic is discussed in the next section of this article. Secondly, for an increasing number of potential cruise passengers these ships are »too big« for them. It seems as if there is something like a limit of acceptance by cruise passengers in terms of capacity. Some cruise passengers might enjoy the anonymity on board of such a big ship, but contrary some people might be afraid of being onboard a ship with 10,000 other individuals (including crew). These different mindsets show the legitimate product diversity amongst cruise products, but also the possible saturation of specific product concepts in the cruise market.

Aida Cruises is the current leading cruise brand in Germany. Taking Aida as an example for the German cruise market, it can be observed that all Aida vessels built from 2007–2013 have or will have a lower berths capacity of approximately 2,000–2,200 beds [8]. Older cruise vessels of the Aida fleet offer a capacity of ca. 1,200 passengers (LB). The latest orders from Aida, announced in August this year, comprise a capacity of 3,250 berths, which is an increase in capacity of 48 % compared to orders up to 2013 and an increase of 170 % compared to the older Aida units. This is a good example for capacity increase of cruise vessels typical for the last decade(s).

After this historical overview on capacity developments throughout the past decades, it is easier to understand the absence of commonly agreed vessel size definitions in the market. Some experts measure by length, others by gross tons or by capacity. Definitions used in one decade may not apply in other decades anymore, as parameters may have changed dramatically. In the past a cruise vessel with 1,000 passengers was already considered a mega liner, whereas today this would rather be called a medium sized ship.

Increasing capacity and large cruise ship dimensions may create challenges or problems. Two sectors of cruising are being influenced by increasing dimensions of cruise liners, namely technics and operations.

Technical challenges of mega liners

The focus of this article is put on the operational challenges concerning large cruise ships. Therefore, only a brief overview on the technical issues is given that may arise with large cruise ships. In the past shipyards and cruise ship construction mainly concentrated on the growing amount of waste, emissions and sewage. Furthermore, a focus was put on efficiency, since engines, fuel and power have been and still are a great matter of expense. Today, from the technical, constructional and environmental point of view, there are no real borders to cruise ship design and construction in terms of dimensions. Technically, there is no problem of facilities and technical equipment to become bigger. Due to common international rules and regulations many facilities onboard, such as waste or water treatment facilities, are the same on small, old, large and new vessels. On todays’ very big ships similar technics and facilities are incorporated, but on a very large scale.

Another important issue for consideration when talking about very large cruise vessels is the availability of shipyards which can dock respective ships and do the class works. Only a limited number of shipyards offer suitable facilities to dry-dock and repair such big ships, which makes coordination hard in case of required repairs.

With increasing cruise ship dimensions, more onboard facilities for leisure purposes are implemented to offer cruise vacationers more diversity. Average or medium-sized cruise vessels like the »Artania« of Phoenix Reisen offer a handful dining options, a show lounge for the entertainment program, some bars, a spa area, one or two pool areas, some sport facilities and a sundeck [9].

A mega liner, such as the »Norwegian Epic« of Norwegian Cruise Line, on the other hand offers more public spaces and activities, such as a large pool area with water pipes, climbing walls, special areas for kids and teens, large spa and fitness facilities, various lounges and bars, diverse dining and snacking options, two story theaters, shopping areas, casinos and dancing options [10]. Different facilities are required to satisfy different target groups.

In addition these facilities, safety appliances for the respective capacity of the cruise vessel have to be placed and stored onboard to comply with IMO [11] and SOLAS [12] regulations. The question that arises on very large cruise ships is, if intensified muster drills should take place as ships may be twice the size of regular ship sizes. The probability of panicking people becomes grater as more cruise passengers are onboard. The crowd of cruise passengers has to be handled and guided accordingly in an emergency situation.

The topic of sustainable cruising and environmental protection is present in today’s media and will keep growing in importance, especially in the public domain within the next years. Cruise ships have to adapt and comply with always new regulations leading to new technical standards. The prominence of this topic is obvious as conferences, such as the Global Maritime Environmental Conference (GMEC) in 2010 or the Seatrade Europe Cruise and River Cruise Convention 2011 both in Hamburg, addressed latest regulations as well as their implications and options.

Operational challenges of mega liners

After the initiation of technical challenges, the focus of this article is put on the operational aspects of big cruise ships. Various issues as well as chances concerning operations and logistics may arise with permanently increasing cruise ship sizes.

In the planning stage of a cruise, companies need to decide for an attractive itinerary. To be considered for an itinerary, destinations must offer certain attributes, such as

• touristic/historical attractiveness to sell tours as well as pre- or post-packages to create additional revenue;

• fitting port/pier size for given cruise ship dimensions;

• required port services like bunker availability, waste disposal and loading zones;

• availability of terminal/pier space on certain dates;

• attractive location of the terminal/pier within the destination.

For exemplary purposes an average cruise vessel of today with a capacity of 1,200 beds, like the above mentioned »Artania«, will be compared to a large cruise vessel with a capacity of 4,000 beds, like the above mentioned »Norwegian Epic«, in various operational aspects.

Onboard differences

To offer a cruise product with a large amount of cruise passengers onboard, each aspect of a cruise has to be as standardized as possible. Standards and manuals for each and every service or task onboard as well as shore side have to be in place in order to get the highest efficiency and human exchangeability. Computer systems help cruise lines and crew onboard to give the cruise customer an individual holiday experience, but still, the individual passenger will receive only an individualized standard service with limited personalized features.

Cruise vessels with large or very large capacities are usually not exclusively sold within one source market, but offered to various markets. Hence, passengers may speak different languages and have different cultural backgrounds which have to be taken care of during a cruise. Consequently, multilingual guidance and culturally fitting programs must be available in every aspect of the cruise. Furthermore, announcements and printed material must be available in different languages and new technical solutions for information purposes must be provided such as screens and/or personal handheld devices.

Infrastructure requirements

Prior to a cruise, the cruise company (or respectively the travel agent) arranges transportation for the cruise passengers and therefore has to book flights or even has to full-charter planes, busses or trains to get the passengers from their home to the destination of embarkation. Especially with a large amount of people, cruise lines have to decide for destinations with frequently visited airports from diverse countries when planning the cruise vessels’ itinerary to make the cruise attractive considering accessibility and price for the potential cruise customer. But an airport is not the only required facility. The accessibility of a railway station is also required by passengers especially but not exclusively from the source market of the destination. Some national or international passengers might arrive by car, taxis or busses, which all require parking space around the cruise terminal.

The entire infrastructure of an embarkation/disembarkation destination has to be functional for the corresponding amount of cruise passengers. A cruise line, which operates a large ship with 4,000 passengers, is in need of a cruise terminal, which can accommodate and organize at least 4,000 disembarking as well as 4,000 embarking cruise passengers simultaneously. Although lots of organizational planning is done, embarking cruise passengers from various countries arrive at different times and hence need to be offered a waiting hall with sufficient bathroom facilities, food & beverage facilities and preferably assistance with their bags and luggage, which often need to be stored for hours before embarkation time. Passports have to be checked, security measures need to be applied and passengers have to be checked in. These steps all require designated areas within a cruise terminal.

Passenger luggage handling is part of the ground handling. On average each cruise passengers brings 1.5 suitcases [13] when taking a cruise. In case of full occupancy of our exemplary mega liner, 6,000 suitcases of embarking as well as 6,000 suitcases of disembarking cruise passengers have to be handled by the cruise terminal. In sum this is 12,000 suitcases for only this one exemplary very large ship. Comparing this amount of suitcases with an average cruise vessel of 1,200 passengers, only 3,600 suitcases would have to be handled at once.

Parking space must be available for excursion busses as well as for trucks that equip the cruise vessel with required provisions. The necessary loading space for buses and trucks should not be underestimated. If only two third of the passengers of our reference mega liner are taking a guided tour by bus, then more than 50 excursion busses are needed. The average cruise vessel would only need 15 busses. Furthermore, cruise lines have to ensure a sufficient amount of destinations, where a large amount of provisions can be loaded. This is a logistical challenge, as not every destination offers a sufficient amount or quality of food which is required for a mega liner. Hence, provisions are being imported on a large scale often via containers. One of the most important ports of shipment for northern European cruises is Hamburg.

Supplementary, cruise lines require further port services for their operations. Cruise vessels are for example in need of bunker. Next to fuel also fresh water is frequently needed. Although most cruise ships are able to produce fresh/drinking water on their own, sometimes it is easier and cheaper to supplementary buy it. Besides fresh water production plants, cruise ships execute waste separation, recycling and have incineration plants installed onboard. Cruise ships use these facilities during their cruises and after those processes are done, the end products also have to be disposed. This end disposal takes place once the ships are in ports, where required disposal management and facilities are given shore side. Comparing untreated dry waste, the reference mega liner produces ca. 33 tons on a seven day cruise, whereas the average reference ship only produces ca. 10 tons within the same time span [14].

Theoretically, destinations could be able to offer these kinds of services as well as the required spaces, but in reality most destinations lack the resources or infrastructure to offer such required port services. Often, there are no cruise terminals within attractive destinations, or terminals are old and not updated according to the increasing ship sizes and resulting needs. If historically grown, there are two predominant locations of ports. Either the port/terminal is located within or very close to the city center as merchant ships back in the days sailed directly into the city center to trade goods, or the port (mostly container ports) are located outside the city as container-handling demands a large storage area. Both options are not ideal for cruise passengers and cruise passenger handling. If cruise ships berth directly inside the city center and infrastructural foundations are outdated, then traffic jams may occur due to car, truck, bus and taxi congestion during peak times. This, for example, happens frequently in the city of Dubrovnik in Croatia especially if more than one cruise vessel calls the port at a time [15].

Large ships are often too big to berth inside the city centers, as piers are not long enough. Although tourists demand to berth inside the city center in order to take walking tours directly from the ship, sometimes it is also not possible or not wise for large ships to tender their passengers shore side. It takes a lot of organizational efforts and it is not as safe and not as comfortable to tender, since passengers often have to wait in line in order to get on a tender boat. Next to the uncomfortable option of berthing inside the city center with such a big ship, berthing inside a container harbour is also not favorable. Special security measures have to be incorporated and passengers are disappointed that their way into the city center might take 30 minutes to one hour by bus or taxi. Consequently, big ships are in need of special cruise terminals, which offer both, a proximity to the city center, enough parking/waiting space for busses, cars and trucks as well as required port services.

Crowding is another important factor that has to be considered when planning an itinerary. As mentioned before, some destinations are not able to absorb a large number of cruise passengers and they are not able to handle the corresponding logistical issues. Hence, traffic congestion as well as people congestion within the city center may occur, which both decrease the enjoyment of the destination for the passenger and correspondingly the enjoyment of the whole cruise. Unfortunately, in most of the cruising areas slot control has not been successful to be implemented. In this respect the cruise industry could learn a lot from the airline/airport business.

The above mentioned issues of itinerary planning, ground handling, logistics and general organization have to be strictly planned and taken care of with mega liners. The examples show differences of large cruise vessels and average cruise vessels, but at this point it is important to mention that usually not only one cruise ship is present in a destination, but various. For example in August, Barcelona set its record with berthing nine cruise vessels on one day [16]. Maybe not all of those vessels offered embarkation or disembarkation on that specific destination and not all of them are large cruise vessels, but passengers as well as excursion busses, provisions, waste and bunker have to be arranged, handled and organized accordingly on an even greater scale.

Attempts to solve the challenges

All of the above mentioned issues have to be taken care of and call for actions by the cruise lines.

Today, some cruise lines already offer variable cruises, meaning that the cruise passenger can decide which port he likes to embark and disembark on a given itinerary. By offering this option to the cruise passengers, some additional challenges arise. According to SOLAS regulations [17] and various other national as well as international laws, a passenger muster drill shall take place (within 24 hours of the cruise). If embarkation ports are variable, this is harder to coordinate, since cruise passengers do not want to participate in muster drills every day. Some cruise lines, such as Royal Caribbean, Princess Cruises and Carnival [18], have tried alternative ways of muster drills, where life jackets don’t have to be worn or they take place inside with just an informative demonstration. Utilizing this procedure, an additional challenge arises when calling a port where most passengers need to apply for a visa. Passenger lists always have to be kept up to date, as group visas are applied for in diverse destinations. With a large amount of passengers this becomes more complicated and has to be updated daily, but shipboard computer systems assist the purser and reception with these procedures.

A bottleneck arises at berthing, when a large amount of cruise passengers try to embark and disembark the cruise ship via the gangways in a short period of time. Often, cruise terminals/piers are only equipped with one or two gangways, which suit big ships. This again creates people congestion. Cruise lines already try to eliminate this problem by timing excursions with buffer times or allocating cruise passengers different embarkation and disembarkation times according to flight, railway or bus schedules. This usually works well for one ship if passengers accept the given rules, but as more ships berth at one terminal, then things might become more complicated as passengers mix and may get confused.

The same attempt of timing is used for the logistics of provisions and management of port services. Strict time schedules are prepared in order to handle incoming provisions and outgoing waste.

As mentioned before, tendering with a large ship is possible, but not always feasible or wise. Embarkations and disembarkations should not be done via tendering, as luggage has to be handled accordingly. For excursions tendering might be suitable if departure times are timed according to tender availability, but passenger groupings and security controls on board stay very complex and time-consuming.

Conclusion

Large ships equal many passengers. Cruise companies try to utilize economy of scale effects by offering large cruise vessels to stay competitive in the market. As the recent past shows, cruise lines have to find the perfect fit between cruise ship dimensions (capacity), passenger preferences as well as destination availability.

Large cruise ships call for great logistical and operational coordination. The timing of passenger and provision flows play a central role in cruise planning and itinerary scheduling.

Large cruise ships offer diverse leisure facilities for passengers, which compete with the visited destination. Hence, cruise lines try to keep passengers onboard to generate additional onboard revenue, rather than focusing on presenting shore side experiences. Destinations play a subordinate role and often only act as a feeder for bunker and provisions and as a marketing tool, since the ship becomes the destination itself.

Not necessarily cruise lines, but destinations face big challenges in providing adequate terminals, piers, services and necessary infrastructure. Many destinations are adapting or have adapted their facilities to new cruise ship dimensions and requirements. Currently in the Mediterranean, a mega liner with 4,000 passengers and a length of ca. 330 m would for example be able to berth at Barcelona and Piraeus, but not in Venice (max. length 294 m), Dubrovnik (max. length 280 m) or Monaco (max. length 130 m) due to their pier limits [19]. Out of this choice of destinations a cruise vessel like the »Oasis« or »Allure of the Seas« would only be able to berth at Barcelona (unlimited length possible [19]). If sufficient infrastructure is not available in a destination, calls of cruise vessels should be managed or limited accordingly. Thus, one question arises: Who is in charge of managing this? Destinations depend on the income of cruise vessels and their passengers. Hence, they do not have a great interest to limit calls. Cruise lines might not care a lot as they can blame the destination of not being able to handle cruise ships professionally or call destinations, which offer adequate infrastructure or port services. Cruise passengers demand certain »must-see« destinations on their itinerary, but may be quite price sensitive and take what is offered. Within the past years, many cruise destinations around the globe, such as Singapore, Hong Kong and Port Canaveral, announced to either upgrade their cruise facilities or even build new terminals to be able to accommodate and process mega liners.

It will be interesting to see how cruise lines and destinations comply with increasing ship sizes in the future.

Authors:

Helge Grammerstorf,

Miriam Schmenner

SeaConsult HAM GmbH

www.seaconsult.de, info@seaconsult.de

Helge Grammerstorf, Miriam Schmenner