Germanischer Lloyd has developed a design concept for a feeder ship which runs completely emissions free. It would be powered by liquid hydrogen to be produced through the use of renewable wind energy.

Aslim blue vessel slides into view, silently drawing up alongside a gleaming platform. In the distance stately white turbines look[ds_preview] down, their massive blades gently rotating in the wind. Two slim arms swing down from bunkering stations on the platform to each end of the vessel and a short time later the vessel glides off again, over the waters of the North Sea. A vision of the future?

A low carbon horizon

The global fleet is increasing and barring radical change in the nature of the world’s supply chain it will continue to grow. Increased awareness and accompanying regulations have brought SOx, NOx and particulate emission reduction to the forefront of discussions about the environmental impact of shipping. Reductions in carbon dioxide and other greenhouse gas emissions seem set to form the backdrop for future controls.

Efficiency gains promise much, perhaps as much as a 20 % reduction in CO2 emissions across the global fleet. But even such impressive gains will not prevent total emissions from shipping from increasing, let alone hit reduction targets relative to historical figures, for example the emission targets proposed by the EU Commission which call for a reduction in CO2 emissions to 40 % of 2005 levels by 2050.

Global shipping, emitting just under 3 % of global CO2 emissions and thus playing a relatively small part compared to energy generation or road transport, needs to look to innovative designs and alternatives to traditional fuels to meet the ambitious reduction targets that are on the horizon. A possible solution to these challenges is to create a truly zero emission vessel. A holistic model which would produce no SOx, NOx, particulate matter, or greenhouse gases, in either its fuel production or consumption.

The Zero Emission Container Feeder Vessel is such a design concept, created by GL Strategic Research and Development, for a completely emissions free vessel powered by liquid hydrogen. Fuel for the vessel would be produced through wind energy, and the concept is built around a vessel that operates in northern European waters, with a typical round trip of ten days.

Design and principal features of the vessel

The design concept is for a container feeder vessel with a full open top 1,000 TEU intake with 150 reefer slots. The open top design reduces loading and unloading time, creating efficiencies in port helping to reduce emissions as the vessel is longer at sea and can reduce speed compared to a standard vessel which remains longer in port. The vessel has standard principal dimensions but a reduced design speed of 15 kn to reduce the required propulsion power.

There are two power generation rooms, situated forward and aft. The vessels uses two podded propulsors for its primary propulsion and a »take-me-home« thruster provide for extra manoeuvrability and drive redundancy.

The vessel would rely on a 5 MW fuel cell system for propulsion, made up of ten linked 0.5 MW modules. This system would be powered by LH2, stored in multiple pressurised type C tanks, holding 920 m3. This storage capacity would hold enough LH2 to power the vessel over a typical ten day round trip. Based on GL’s study for an LNG-fuelled container feeder vessel in 2009, it is estimated that approximately 6 % of the TEU capacity of the vessel would need to be sacrificed for the hydrogen fuel tanks. With tanks feeding the fuel cells both forward and after, the concept envisions a dual bunkering approach to achieve a refuelling time of three hours.

Fuel cells typically cannot generate peak power rapidly and because of this a 3 MW battery system, charged by the fuel cell system, would provide additional power for peak usage.

Investment costs

The LH2-fuelled container vessel has significantly higher investment costs than a similarly sized vessel of traditional design. Based on data from a GL market study on fuel cell systems and the aforementioned 2009 LNG feeder vessel study the cost of the LH2-fuelled vessel is estimated at approximately 35 million US$, 60 % higher than an HFO/MGO fuelled vessel (22 million US$). The largest part of this increase is associated with the fuel cell system (57 % of additional costs), the type C tanks (37 %) and the battery system (6 %). This estimate assumes that the costs associated with fuel cells production will continue their steady decline, with an expected drop in investment cost by 2020 to 1,500 $/kW.

Offshore production, storage, and delivery of LH2

To be a truly »zero« emission vessel, one has to look not only at the emissions from the vessel itself but of the production of its fuel. This design concept therefore suggests a bunkering station that produces LH2 through the use of renewable wind energy. Electricity generated by wind energy does not result in any CO2 emissions, or create pollution to air and water from other harmful gases or materials.

The 2020 generation target for offshore wind parks operating in the German Exclusive Economic Zone (EEZ) is an installed capacity of approximately 3 GW. One of the disadvantages of renewable energy in its current form, however, is the problem of matching the intermittent nature of the supply with consumer demand. Insufficiencies in the grid and underdeveloped storage technologies mean that wind turbines are often not turning when they could be. Studies have estimated that as much as 30 % of an offshore wind farm’s potential energy generation is not able to be fed into the grid.

Based on this up to 3,600 GWh per year of the energy generation potential across the EEZ is potentially available for extra grid uses, for example, liquid hydrogen (LH2) production. Taking these estimates, a 500 MW wind farm could produce up to 10,000 t liquid hydrogen using its generation surplus. This could then serve the bunkering needs of five feeder vessels of the size presented above.

The hydrogen produced would then be liquefied and stored in tanks. Intermediate storage of LH2 for up to ten days would require insulated tanks of up to 5,000 m3 to be installed. With the wind park operating approximately 4,000 hours per annum the price of LH2 would be up to 7500 US$/t. These costs include production, liquefaction and storage on site.

Competitive with MGO in 2025

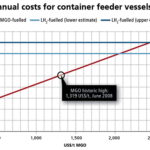

Based on GL estimates liquid hydrogen produced through wind power could begin to be commercially attractive as an alternative to MGO in the 2020s, if MGO prices increase to 2000 US$/t. To arrive at this estimate, annual costs for a LH2 fuelled feeder vessel, including fuel costs, other operating costs and annualized capital costs, have been compared with the annual costs of a standard container feeder vessel, using MGO as fuel and operating inside of an emission control area (ECA). The difference between current MGO prices and the expected price level required to make LH2 commercially attractive should be considered in light of MGO prices over the period 2000 to 2010. During this decade, MGO prices increased from 250 to 650 US$/t, with an intermediate peak value of 1,319 US$/t in June 2008.

The pressure to reduce greenhouse gases will only increase over the coming years and 2020 is a date within the lifetime of many vessels currently operating. To reach the target of reducing CO2 against historic levels, new technologies must be implemented. This vision of a zero emission vessel shows how new technology can contribute to meeting such targets and propel the industry into the future.

Dr. Pierre Sames