It is anticipated that within this decade a considerable share of new ships will use gas fuelling. Until 2020, the key issues sulphur and nitrous oxides as well as particles will have a significant regulatory impact.

International shipping is a heavily regulated industry. Nevertheless, this decade will see plenty of additional regulations coming into force, with[ds_preview] significant economic and operational implications. »Managing the cumulative impact may be one of the decade’s key challenges, and companies that do not make the right choices may see their long-term viability suffer«, explains Erik Nyhus, Director Environment of Det Norske Veritas (DNV).

Stricter environmental regulations

Today, DNV is a global provider of services for managing risk. Originally the company came from creating safety in shipping, later better known as maritime industry. Established in 1864, DNV now is an independent foundation with the purpose of safeguarding life, property and the environment. Having large oil and gas fields just off their rocky coast, Norway and DNV, together with its home nation, became engaged in developing safety for the exploration and exploitation of these new energy resources. These new times began in the late 1960s.

Recently, DNV stated in its »Technology Outlook 2020«: »Impending stricter environmental regulations that require that the emission levels of SOx (sulphur oxides), NOx (nitrous oxides) and PM (particulate matter) are reduced, and probably CO2 also, are pushing the maritime industry towards using cleaner energy sources. Increases in bunker oil prices will probably accelerate this transition.« Abatement technologies, such as exhaust gas recirculation, scrubbers, or catalytic reduction, can meet some of these regulations, but typically CO2 emissions are increased. Alternatively LNG (liquefied natural gas), bio-fuel blends, or more radical energy sources like wind or sun could be exploited. The implementation of these new technologies could face significant technical and economic challenges, and the time frame ranges from a few years for LNG to decades for wind or sun.

Shipping as emission source

SOx, NOx and PM are all emissions into air that result from combustion of marine fuels. The local environmental effects of these are generally well known and include acidification and eutrophication, both of which have potentially severe ecosystem impacts and negative health effects on exposed populations.

The impacts are generally well understood and in some parts of the world (e. g. the EU and USA) have led to strict regulation of emissions from land-based sources. In recognition of shipping becoming a dominant emission source, emissions have been internationally regulated by the International Maritime Organization (IMO) through the MARPOL Convention (International Convention for the Prevention of Pollution from Ships).

This gives a combination of general maximum global emission levels and significantly more stringent levels applying to designated sea areas generally known as emission control areas (ECAs). The regulations allow emissions to be mitigated by either changing the fuel type or cleaning the exhaust gas.

There are certain key dates that represent crucial regulatory deadlines for shipping:

• January 2015: 0.1 % sulphur (S) in ECA,

• January 2016: NOx Tier 3 in ECA,

• January 2020 or 2025: 0.5 % S global cap.

Prior to 2015, operators will have to choose between installing technically complicated and probably expensive exhaust gas cleaning systems (scrubbers) or switching to low sulphur fuel for all ships operating in an ECA. Low sulphur fuel options will realistically be either expensive distillates or LNG, the latter in practical terms being an option only for newbuildings.

For ships built in 2016 and onwards and operating in an ECA, the NOx requirements add another layer of complexity due to possible difficulties in technically integrating SOx and NOx solutions. Finally, in 2020 or 2025 (pending an IMO decision in 2018) the 0.5 % S global cap will enter into force, changing the economics of the decisions made in the preceding years.

Fuelled by natural gas

A switch to natural gas could virtually eliminate the emission of SOx and particulate matter (PM), and NOx emissions could be reduced by 90 % in gas-fuelled, lean-burn, four-stroke engines. Such engines are suitable for cruise ships, smaller cargo and service vessels, and also for auxiliary power generating. Although natural gas combustion can reduce CO2 emissions by up to 25 % compared with marine diesel oil, emissions of unburned methane represent a problem. Methane is a greenhouse gas (GHG) that is 21 times more potent than CO2. Depending on the engine type, the change in CO2 equivalent emissions range from a reduction of 20 % up to a net increase.

Engines fuelled by natural gas, either as CNG (Compressed Natural Gas) or LNG (Liquefied Natural Gas), are widely used for power generation and transport on land. One challenge for shipping is that LNG tanks typically require two to three times more space than a diesel tank.

Since natural gas must be stored either liquefied or compressed, these storage tanks are also more expensive. Based on recent experience, the new building costs of LNG-fuelled ships are about 10–20 % higher than for equivalent diesel-fuelled vessels.

Although LNG bunkering infrastructure is currently very limited, a significant increase in the number of bunker stations is expected by 2020, especially within ECAs. Strict regulations on NOx and SOx emissions, combined with a more competitive gas price, will drive the uptake of gas as marine fuel. It is anticipated that within ten years a considerable share of new ships will have natural gas fuelling, particularly in short sea shipping. It might also be expected that in the coming years some ships are retrofitted to run on LNG.

Clean design notation

Generally, shipping is an energy efficient way of transporting goods, but it is associated with a number of negative environmental effects. The environmental legislation process has been slow when it comes to shipping. However, the industry has every reason to increase its environmental performance as there are many technical solutions to reduce the negative environmental impact. A clean shipping project was started in Scandinavia in order to increase focus on the environmental issues of shipping. And with over 20 of Sweden’s largest cargo owners as a dynamic part of the project it has become a force to be reckoned with. One of the results of this project so far is the »Clean Shipping Index«, an index taking a holistic perspective on the environmental issues of shipping.

Some of the classification societies, e. g. DNV, followed this project with great interest and created a specific class notation. DNV’s clean design notation requirements are intended to reduce and limit the ship’s air emissions and sea pollution. In addition it stipulates defensive designs, accident prevention and consequence limitation requirements, thus providing additional environmental protection. The image of the individual ship owner and operator will clearly improve with customers and authorities, since the notation demonstrates that the company’s policy is to be environmentally proactive in order to prevent accidental pollution, too.

World’s largest LNG-powered ferry »Boknafjord«

At the end of 2011, the naming ceremony of the double-ended fjord ferry »Boknafjord« took place in Norway. The ferry started its service on the Boknafjord between Mortavika and Arsvågen in southwestern Norway, a fjord area with very harsh shipping conditions.

The vessel was contracted by the Norwegian operator Fjord1 to the shipbuilding company Fiskerstrand BLRT (hull no. 09). Its subsidiary Western Baltija Shipbuilding in Klaipeda/Lithuania built the hull and all steel structures. Late in July 2011, the hull was towed to Fiskerstrand Verft in Norway, near Ålesund, for the final outfitting (hull no. 71). Today the ferry is the world’s largest which is completely fuelled by LNG.

This new gas-operated ferry has been designed by Multi Maritime in Førde, Western Norway. It has two car decks capable for carrying 242 cars on altogether 396 m lanes and accommodating 600 passengers in a mainly covered deckhouse above the car decks. On top of this, there are rest rooms for the crew, and finally the structure is crowned by the navigating bridge with a free 360° view. Loading decks are curved partly down into the hull and can be closed watertight as well as partly up in open air under the superstructure. For loading and unloading, the visors at bow or stern can be raised to allow the cars to roll in on up to three lanes simultaneously via terminal-based ramps ashore. The curved decks are arranged to overcome a level difference of up to 1.50 m between high and low tide at ports. For average traffic levels, turnaround time is only three to four minutes in each port.

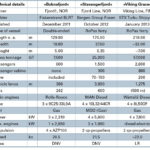

The underwater hull is fully symmetrical fore and aft with bulbous bows and two Rolls-Royce Azipull thrusters AZP100 each at both ends. Energy is generated by three Rolls-Royce Bergen gas engines of the C 25 type: three L9A and one Bergen C series diesel engine. All engines are directly coupled to generators creating electricity which is led to the places where it is needed. The gas engines produce 3 x 2,310 kW while the diesel engine provides 2,850 kW power. Environmental concerns have high priority for this new ferry, therefore it meets DNV’s clean design notation. The Rolls-Royce engines meet IMO Tier 3 emissions regulations already, which are not due into force until 2016. The machinery room configuration ensures that there is redundancy and enables the vessel to meet DNV’s RPS (redundant propulsion) class. Splitting the ship down the centre fore and aft, then one part would have the two forward engine room compartments and one gas tank, mirrored in the aft section. The ferry is classed »DNV + 1A1, Car Ferry A Gas Fuelled, CLEAN, RPS, EO, R3 (NOR)«.

RoPax ferry »Stavangerfjord«

The first of Norwegian Fjord Line’s two new cruise ferries for the North Sea was launched at the Stocznia Gdansk Shipyard in Poland on 4 April 2012. The ship will be named »Stavangerfjord« early in October, just before the delivery. The hull was towed to Bergen Group Fosen in Rissa near Trondheim to be outfitted and finished there. The ferry is going to operate on Fjord Line’s routes from Bergen/Stavanger to Hirtshals in Denmark and back again. The trip takes 17 hours and is currently offered every other day in each direction. When the new sister-ship »Bergenfjord« comes into service next year, daily trips in both directions will be possible.

Due to the sailing time of 17 hours, accommodation in cabins and a variety of restaurants will be installed on both ferries. The speciality of these ships, however, is their machinery. The engine compartments are designed to allow the ferries to run on LNG, when environmental regulations require it. This might be the case after 2015. Until then the ships will be operated on conventional fuel such as HFO or MDO (heavy or marine diesel oil).

Taking care for these future requirements, the yard and the ferry operator chose the well proven MAN 32/44CR common rail diesel engine for their main engines. It combines low emissions with excellent fuel efficiency, in the chosen design a ten-cylinder series version, an assembly that can deliver 5,600 kW per engine. The engines’ eco-friendliness is of particular importance, as the North Sea and the Baltic are becoming emission control areas in which particularly stringent emissions legislation are due to come in force.

To comply with these strict specifications it is planned to convert the engines with a retrofit into dual-fuel engines at some given time in the future. Currently, this is still under development and will therefore be installed within the next few years. This retrofit will enable the engines to be switched from operation with liquid petro fuel to eco-friendly natural gas at the press of a button. The space for the required gas tanks on board has already been considered in the design phase.

RoPax cruise ferry »Viking Grace«

Early this March, the keel laying of hull no. 1376, an environmentally friendly new generation cruise ferry to be built for Åland-based Viking Line, was performed at STX Turku Shipyard in Finland. This vessel represents a new generation of passenger ferries fuelled completely by LNG and therefore being able to operate in ECAs.

After the completion in early 2013, the new ferry will be named »Viking Grace« and is going to operate mainly on the route Stockholm–Mariehamn–Turku. The ship is considered to be the most environmentally friendly cruise ferry ever built. It will be fuelled by liquefied natural gas, discharge and pollution into the sea will be eliminated as well, and emission into the air will be significantly lower than that of any other cruise ferry and even cruise ship in the world.

The power generation and propulsion machinery are supplied by Wärtsilä, the marine industry’s leading Finnish solutions provider. The scope of supply includes four main engines type 8L50DF (eight cylinders inline dual-fuel engines with 500 mm bore), transverse bow and stern tunnel thrusters, as well as two stainless steel fixed pitch propellers with shaft lines including sound shaft line seal systems, the LNG tanks and fuel supply as well as handling equipment with safety and automation systems. The electric power, which is generated by the LNG engine, will be distributed electrically to the places where it is needed.

Due to the lowest possible pressure impulses generated by the propellers, the vibration level in the stern hull will be rather low. Wärtsilä will also supply a sound-absorbing system to minimise noise from the engine, thus increasing passenger comfort. A low noise level is important as the vessel’s route passes through the Turku and Stockholm archipelagos.

Klaus Nienaber