Esa Henttinen from software house Napa suggests that options for SEEMP

implementation mean that it is much more than a »paper tiger«

The deadline for implementing a Ship Energy Efficiency Management Plan (SEEMP) for all vessels – January 2013 – is moving unerringly closer[ds_preview]. Some forward-thinking companies have announced that their fleets are prepared but it is difficult to know whether the shipping industry as a whole has given SEEMP the level of consideration it demands. For some in the industry, SEEMP is viewed as a »paper tiger« – a time-consuming exercise in paper pushing for officers on board and their shore-based colleagues that will have little impact on the efficiency of real vessels. However, if one considers SEEMP in the spirit it was intended, it could become the catalyst needed to refresh a company’s operational policies, putting it on the road to greater eco-efficiency and, through fuel savings, greater profitability.

Early adopters

For some, this is by no means the first foray into measuring and managing energy use on board. As far back as 2005, Napa worked with cruise ship owners to develop methods to monitor the energy usage on their vessels. The system that was developed was not designed with the implementation of new technologies or fundamental changes to the vessel in mind, but was created to optimise the equipment already installed – managing power use more effectively and understanding how the vessel travels in whatever environmental conditions it is facing. This is the approach that is being championed by the IMO through legislating the international fleet-wide implementation of SEEMP.

Cruise operators, whose energy requirements extend far beyond those of a typical tanker or bulk carrier, should perhaps be viewed as early adopters of this approach. Many »early adopter« cruise operators chose to collaborate with software providers, such as Napa, to develop a high-spec software solution that would enable them to record and analyse data, and therefore manage their energy use in »real time«. This targeted and measurable management of efficiency is starting to develop a reputation as the »best practice« approach.

Indeed, ClassNK, the world’s largest class society, is working in partnership with Napa to develop a similar system for its customers, combining ClassNK’s technical experience and expertise with proven technologies to create a world-leading software solution for both newbuildings and existing vessels.

Paper versus digital?

Despite this increasing acknowledgement of the digital approach, many owners and operators bringing in mandatory SEEMP will be asking their crews to complete paper-based reporting. For both shoreside offices and those on board, this will present several challenges relating to implementation, analysis and responsiveness that could be negated by a digital system.

In many ways, the adoption of recording and reporting processes using a paper system gives truth to the critics’ claims that SEEMP simply adds further duties to the already hectic schedules of crew members required to take measurements and record initial data. Once these duties have been completed a by-hand analysis and interpretation of the data must be undertaken to establish whether the measurements show a vessel operating at optimal efficiency – a burdensome task for a human, but the work of seconds for well-designed software. There is then a delay between the analysis of the data and the results being made available to the shore-based office for review and benchmarking against other vessels in the fleet.

Real time efficiency improvements

During the final leg of the SEEMP process, once an inefficient section of the vessel has been identified, a plan to increase efficiency must be put in place and enacted. With the ship-shore connectivity of a software solution this could happen in »real time« and an almost instantaneous response could be seen in the data being measured. However, on paper this process can be a time-consuming process – issuing instructions to the vessels, enacting new procedures, measuring and analysing data, and sending new reports to and from the vessel.

Moreover, software solutions will provide operational efficiency data in the form of tailored reports for each level of responsibility. For example, a company CEO will see a top-line over-

view of a fleet’s data, whereas the superintendent would receive a more comprehensive vessel data set, reflecting their responsibilities and needs.

Once benchmarks for performance are in place, systems allow immediate identification of inefficiencies or identification of a vessel performing sub-optimally compared to its sisters. The reports also utilise »traffic light« indicators to give clear visual clues on efficiency in addition to the hard data.

Instant ship-to-shore connectivity can also mean that once new procedures are implemented then the results can be viewed by all key stakeholders – enabling continual management and finessing of each of the elements contributing to vessel efficiency.

Potential to save 15–20 % in fuel economy

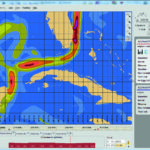

Importantly, it is not only this sort of analysis and measurement that can be implemented by these systems. Napa’s system also incorporates weather routing, propulsion resistance management, voyage and speed optimisation, trim optimisation, management of the floating position and many other elements that can be effectively controlled to increase operational efficiency. When these elements are used properly and matched with sound management systems there is the potential to save 15–20 % in fuel economy, depending on the vessel type, in addition to meeting SEEMP compliance.

With bunker prices at record highs, just 1 % fuel cost saving on a handymax vessel could equate to 50,000 $ saved for the operator annually; this increases to as much as 500,000 $ for large containership.

Such savings could make all the difference to a company’s bottom line across a fleet of vessels, and when savings of 15–20 % are possible the impact could be extremely significant.

January 2013 presents owners and operators with a challenge to not only measure the energy efficiency of their vessels in line with SEEMP legislation, but to also proactively engage with setting targets and making changes that can have a real and immediate impact upon their own – and their customers’ – bottom line. Compliance may be the primary goal, but at a time when fuel economy is being increasingly scrutinised by charterers and shippers, software solutions offer the capacity to differentiate forward-thinking companies from the pack.

Author:

Esa Henttinen Vice President, Business Development Napa Group, Helsinki/Finland

Esa Henttinen