There is still significant potential for further improvement in hydrodynamic design for minimized life-time fuel consumption. A glimpse at what may be achieved in the next decade is given by Karsten Hochkirch and Volker Bertram

The term (hull) »optimization« has been widely used and in many cases abused. Often the term »improvement« would be more[ds_preview] appropriate than »optimization«. Often people say »optimization« if they generate a few variants, analyze them by a flow code, study the results and generate perhaps one or two more candidates and then select the best of these few. This is standard design procedure and employed by many model basins, but frequently we see in our experience that significant improvements beyond this approach are possible.

In general, optimization means finding the best solution of a limited or unlimited number of choices. Sometimes, while the number of choices is finite, it is so large that it is impossible to evaluate each possible solution. And often, the number of choices is infinite. Obviously, depending on how the problem is formulated and on how many candidates are evaluated the »optimum« result will vary and it is thus possible to improve an »optimized« hull, sometimes considerably. This is naturally confusing for people not familiar with hull optimization. Thus, »hull optimization« can mean very different things and lead correspondingly to different results. There are some main elements in hull optimization that determine how close you may get to a hypothetical optimum.

Design variation

Candidates (= possible hull shapes) need to be (automatically) generated. This happens in changing some control »knobs« (the official term is »parameters«) which change, for example thickness of a bulbous bow, entrance angle, centre of buoyancy, width etc. Few parameters mean few possible shapes. A shoebox is described by length, width and draft. But even the best flow code and the best optimization algorithm will not get you a good ship if you limit yourself in your model set-up to a shoebox. Experience helps in reducing the number of parameters and still getting significant progress.

Model set-up including objective function(s)

The main difficulty lies in formulating the objective and all the constraints. If the human is not clear about his objective, the computer cannot perform the optimization. For hull design, older optimization attempts targeted to reduce the calm water resistance at design speed, often even only the wave resistance. Optimization of the resistance (ship hull without propeller) is simpler, but the hull shape of least bare hull resistance is not the same as the one for least power requirement (at design speed), particularly for full hulls like bulk carriers and tankers.

And the hull of least power requirement at design speed may yet again differ from that with least fuel consumption over lifetime. Some software also displays performance of all analyzed variants over investigated changes, thus forming a map of the design space. This frequently helps in trading off compromises and helps the designer making up his mind on what is important for him in his design.

Candidate evaluation

Objective functions (e. g. power requirement, resistance in calm water) and constraints (e. g. GM, displacement) need to be evaluated, typically by numerical approximations. For flow computations, various approximations are used. Simple methods are fast, accurate methods are slow. Unfortunately, the matter is even more complicated as simple methods may work satisfactorily for certain ships, and not for others.

Optimization strategy (algorithm)

The actual optimization algorithm plays a secondary role in our days. Suitable robust algorithms for global optimization are widely available. Most modern applications employ evolutionary algorithms like »genetic algorithms« which are easily implemented on parallel computers and generally find the global optimum within the mathematical set-up of the problem (The best ship hull may still be different, as explained above).

Past – historical development

From early beginnings to the 1960s

Hull design is traditionally based on model tests and/or numerical simulations. Both trace there very roots back to the 19th century. In 1861, William Froude presented a paper to the Institution of Naval Architects, outlining similarity laws for model tests. In 1879, the first model basin was built in Torquay, soon to be followed by many others around the world. For almost a century, model tests would be virtually exclusively by industry to evaluate hull forms and guide hull form »optimization«.

By the early 1960s, computers became available for selected naval architects. These were central computers with punch cards or punch strips as input. First applications were in hydrostatics, then structural analysis. The beginning of numerical ship hydrodynamics is usually seen with the work of the Australian mathematician John Henry Michell who in 1898 proposed an integral expression to compute the wave resistance. However, Michell’s theory and all subsequent refinements of quasi-analytic approaches remained academic for many decades, until numerical methods appeared that captured physics and geometries much better.

Optimization methods have been known for a long time. The Simplex algorithm for example dates back to 1947. By the 1960s, the »classical« (local) optimization algorithms were documented and validated for assorted optimization problems. There were first attempts to combine thin-ship or slender-body theory with formal optimization to derive »minimum resistance« hull shapes, but the resulting hull shapes invariably looked strange with wavy waterlines or decanter-like hull sections in the bow.

1970 to 1990

Computers became more powerful and more widely available, for example in the form of personal computers. Interfaces moved from line-oriented to graphical user interfaces (GUI). In the wake of growing hardware power, we saw also rapid developments in CAD (computer aided design) techniques, CFD (computational fluid dynamics) and optimization strategies. Boundary element methods (panel methods) for propellers and wave resistance of hulls developed to industry maturity. Viscous CFD methods appeared in other industries and around 1990 the first RANSE (Reynolds averaged Navier-Stokes equation) simulations for ships showed up in research applications.

Genetic algorithms were described in 1975 by John H. Holland as application of evolutionary strategies in computer simulations. But genetic algorithms remained largely ignored for years to come as they were computationally much less efficient than classical optimization algorithms on single processor computers.

In Germany, Schneekluth, Nowacki and Söding pioneered applications of optimization in ship design. In the mid-1970s, Söding developed »Chwarismi«, an optimization shell designed to allow ship designers to set up their own optimization models. In parallel, concept exploration models (CEM) were developed as an alternative to »automatic« optimization. In CEM, candidate solutions were kept and plotted so that the designer could get a feeling how certain variables influence the performance of the design.

Furthermore, some research applications of ship hull optimizations were presented, predominantly employing classical thin-ship or slender-body theories. These attempts remained unsuccessful, as the resulting hull shapes were unacceptable from production, operational or even real hydrodynamics point of view.

1990 to 2010

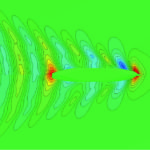

Computers continued to become more powerful in the last two decades, with multi-processor architectures and graphical processing units. The progress in hardware allows much larger (and more realistic) applications. Wave resistance codes (based on potential flow theory) were standard industry tools by the year 2000. These codes are extensively validated with capabilities and shortcomings well known within the ship hydrodynamics community. Typical representatives are »Shipflow« (XPAN), »Rapid«, »nu-Shallo«, and »FS-Flow«. Viscous CFD applications (using RANSE solvers) develop dynamically. With particular relevance to hull form design (optimization) are free-surface RANSE applications capturing also breaking waves and moving-grid applications (for propeller-hull interaction with moving propellers).

Genetic algorithms (GA) became much more attractive with the advent of parallel computing. Consequently, GA and related evolutionary strategies (e. g. particle swarm optimization) became standard technologies which were implemented in optimization shell. Optimization shells became more powerful and more user-friendly, e. g. with graphical user interfaces and capabilities to run applications on different operating systems. CEM and optimization merged under the label »multi-objective« optimization, offering charts of the influence of design parameters on objectives before deciding on constraints and weights on individual objectives. Two commercial optimization shells stand out for ship hull optimization:

• »modeFrontier«,

• »Friendship Framework«.

Earlier attempts at formal hull optimization based on wave resistance codes still result in shapes that, while not unfeasible, are not acceptable for industry purposes. Besides resistance many other aspects have to be taken into account when modifying a ship hull, to avoid unreasonable shapes. The combination of optimization algorithm, flow code, and parametric description per se is not enough. The elements must be skilfully combined to achieve results for demanding industry requirements.

Several research projects involving academia and industry supported the transition from research to industry. In the wake of these projects, we enter the »present« with many commercial projects for ship hull optimization. The applications cover a wide range of ships, from slow tankers to fast semi-displacement yachts.

Present – state of the art in ship hull optimization

The increasingly realistic models and the demonstrated improvements that can be achieved compared to the »standard« approach (using limited manual variations and assessing them by CFD, the »optimization« of the 1990s) led to increasing industry acceptance.

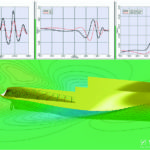

A case study may illustrate how state-of-the-art hull form optimization was applied around 2010. The shipyard Peene-Werft approached FutureShip’s team to improve free running performance of their emergency offshore tug project (200 t bollard pull). Although model tests of the initial design had already shown that the contractual free running speed could be reached, the ordering German tug operating consortium was committed to allow for a comfortable leeway for reaching design speed while investigating for options to reduce the operating costs and emissions. FutureShip’s team was therefore commissioned to conduct a formal hull shape optimization of the forebody to further reduce resistance and thereby increase the free running performance.

The formal optimization process allows investigating a much larger number of candidate designs (more than 20,000) than in the already conducted state-of-the-art design process (up to 20). The main optimization objective was a minimum calm water resistance at free running operating speed and design draft, subject to some design constraints: maintain or increase displacement, centre of gravity, initial metacentric height, and bollard pull.

Additional constraints were length over all, and some hard points to accommodate the bow thruster as well as a minimum beam at main deck level. The optimization achieved more than 20 % savings in required power at design speed compared to the initial design. Positive »side effects« were a favorable forward shift of LCB (longitudinal centre of buoyancy) reducing the need for ballast and improved seakeeping performance in terms of motions and added resistance. The presented case is particularly positive, but not singular.

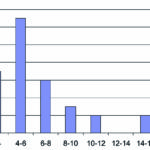

The potential for improvement (in calm water resistance at design speed) varies, depending on the share of the wave resistance on the total resistance and on how much effort was already spent on the hull design. For example, a formal optimization may offer 2–4 % improvement for containership hulls that are deemed already »optimized« in limited form variations with CFD and model tests in model basins.

For fast ships (such as fishing vessels, megayachts or ferries), the potential is larger as the wave resistance accounts for a larger percentage of the total resistance. For an offshore supply vessel, savings of 16 % were obtained in one case. The range may thus be given as 0–20 %, with 4–6 % as typical values.

Both the number of projects and the scope within a typical project continue to increase. In response, we updated our computer resources. In 2011, our parallel computing cluster was extended to a total of 6,600 cores. Correspondingly, storage capacity was extended to 36 TB (Terabyte). Rapid internal network communication was ensured by an Infiniband network with a data rate of 40 GBit/s. With increased computing resources, the door is open to more sophisticated applications.

Future – research projects and extrapolation to 2020

The development of hull optimization has been very dynamic over the past decade and is likely to continue to be so for the coming decade. Predictions for one decade are reasonably justified by extrapolating current research activities, applications seen in neighbouring industries and progress in individual elements of the optimization process that require »merely« integration into industrial applications.

The exponential growth in computer hardware continues, not only for supercomputers but also for personal computers. It is safe to assume that at least for the next decade we will see this growth maintained. Cloud computing, i.e. renting »unlimited« hardware and software as a service over the internet, is widely seen as the next step for high performance computing.

The growth in computing power, available for everyone, lays the foundation for more advanced optimization applications. However, the desire for ever more sophisticated applications is likely to let computational requirements grow faster than hardware unless optimization approaches are changed as well. It is likely that we will see various techniques to make optimization projects more efficient on the software side as well:

• Hybrid computing mixing low-fidelity (e.g. potential flow solvers or CFD with coarse meshes) and high-fidelity (CFD with fine meshes) approximations.

• Meta-modelling where response surfaces yield fast estimates based on variants from actual, extensive CFD evaluations. Such response surfaces can be updated during the optimization process getting dynamically more and more accurate.

The CFD software appears to be mature enough to change little for the hull optimization applications. However, more sophisticated models should evolve over the next decade. Such models may add complexity in various forms:

• More sophisticated seakeeping models, especially for added resistance in waves. RANSE solvers have been applied to compute added resistance in waves, capturing both contributions from motions and wave diffraction/reflection. Such computations, coupled with meta-modelling and initially using coarse meshes, may drift gradually into industry applications over the next decade.

• Operational profiles will be considered rather than a single design point. The consideration of operational profiles (where for example 80 % of design speed is the most frequently operated speed) has been shown to offer fuel saving potential of several percent points. Consideration of matrices of load conditions and speeds is theoretically feasible and likely to become standard as computing power becomes available and design for actual fuel consumption will gain in importance.

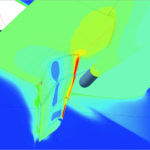

• Hull optimizations will include propeller and appendages, eventually also allowing changes in the geometries of propeller and appendages. In intermediate steps, we will see first propeller optimization for given aftbody (including appendages) and optimization of selected appendages, especially rudders and propulsion improving devices.

• Some design aspects, e.g. manoeuvring aspects and production aspects, are now only qualitatively considered in the way the parametric model is set up and constraints are imposed. Here more sophisticated methods to quantify these aspects may be added to optimization models.

Conclusion

Over the past two decades hull optimization has progressed from »exotic« research applications to widely accepted state of the art in hull design. Similarly, there is wide scatter in what is used in industry today, reflecting in some cases what was state of the art more than a decade ago. How much progress can be expected from an optimization depends on how sub-optimal the starting design is, but also on how good the optimization model is.

Authors:

Dr. Karsten Hochkirch

FutureShip GmbH

Potsdam/Germany

karsten.hochkirch@GL-group.com

Prof. Dr. Volker Bertram

FutureShip GmbH

Hamburg/Germany

volker.bertram@GL-group.com

Note: This article is a shortened version of a paper presented at 11th International Conference on Computer Applications and Information Technology in the Maritime Industries (COMPIT ’12) in Liège/Belgium. For references, further reading and freely downloadable proceedings please refer to the website www.compit.info

Dr. Karsten Hochkirch, Prof. Dr. Volker Bertram