Doping fuel oil with small quantities of water improves combustion efficiency and thus achieves better specific fuel consumption of marine diesel engines. Blue Ocean Systems developed an emulsifier to be used for accurate consumption measurements at once

The price of marine fuels has sky rocketed in recent years from about 400 $/t for HFO in 2010 to more than[ds_preview] 600 $/t today. Reducing fuel costs has become one of the priorities of shipowners. Different technologies claiming fuel savings ranging from 2 % to more than 10 % are being marketed to shipowners looking for every means of saving every drop of fuel. These include: emulsified fuel systems, self polishing paints, air bubbles hull lubrication, all types of stern and propeller vortex/drag reducers, bulbous bow optimization, fuel and lubricant additives, sludge homogenizers, slow steaming, engine de-rating, low temperature heat recovery, dynamic trim systems, voyage/fleet management and optimization and so on. Test results at sea trails are frequently obfuscated by changing weather and sea conditions. Shipowners can be overwhelmed and it can be daunting to figure out whom to trust with the myriad of claims. Therefore, it is imperative that there must be a reliable and accurate method of verifying the savings claimed, to separate the wheat from the chaff.

Emulsified Fuel System

Blue Oceans Systems’ Emulsified Fuel System (BOS EFS) works by producing stable water-in-fuel emulsions to improve injector fuel atomization and combustion efficiency. The key innovation of BOS EFS is the patented emulsifier, which is superior to older devices like homogenizer, cavitation and ultrasonic type emulsifiers. Unlike the older devices, BOS emulsifier has no moving, cavitating or vibrating parts that suffer from rapid wear and tear in the engine room environment. It is designed to produce optimal emulsions on demand to achieve 2-5 % fuel savings consistently and reliably. The optimal emulsion has water content of 10 % v/v and water-in-fuel particle sizes of 2–8 µm. In a HFO system, unconsumed emulsified fuel after the engine, is re-circulated back to the close-loop fuel system as shown in Fig. 1. The BOS emulsifier re-emulsifies the water-in-fuel emulsions to exactly the same optimum emulsion of the 10 % v/v water content and water-in-fuel particle sizes of 2-8 µm which is a magnified picture of an optimal emulsion sample. BOS emulsifier is able to achieve this consistently and reliably because of two design characteristics which were developed after extensive R&D:

• the water content is controlled automatically using feedback control to ensure accurate dosage of water even in extreme fluctuations of fuel rates;

• it is designed parametrically to ensure sufficient energy to break the water particles to below 8 µm but not with sufficient energy to smaller than 2 µm.

Older type devices would produce particle sizes that are either too small due to repeated re-emulsification, or too big due to wear and tear. This is the key reason why BOS EFS works while others do not, when decades of comprehensive R&D and proven laboratory tests were applied to actual ship board implementations.

Reliable and accurate verification

Since the 1980s, it has been recognized that the fuel consumption measurement on ships has been inaccurate and shipowners had viewed the results with distrust. There was neither no common standard nor reference for measuring the performance of ship’s engines at that time. Since then, ISO 3046 and ISO 15550 have been established to provide the common standards to measure and determine the performance of engines. The results are generally plotted as specific fuel oil consumption (gm/kW-hr) against power (kW). The specific fuel oil consumption curves (SFOC) allow the fuel efficiencies of different engines to be compared on a apple-to-apple basis.

In applying ISO 3046 and ISO 15550 to measure the performance of the engine at sea, many parameters need to be measured and recorded. Some of the parameters are: speed over ground and through water, wind speed and direction, wave height and heading, draft fore and aft (trim), engine power and rpm, fuel consumption rate, fuel temperature at flow meter, viscosity, temperature after viscometer and before engine, fuel governor/racks indices, ambient temperature, barometric pressure, relative humidity, sea water temperature or charge air coolant temperature, lower calorific value of fuel, energy consumption of auxiliary equipment, water content (%), etc.

Generally, the wind speed should be less than 15 kn and the sea state should be below 4 bft during each measurements. It can be seen that the measurement of engine performance at sea can be fairly complicated because many parameters must be measured and recorded. Determining the improvements of engine performance when fuel saving technologies are implemented can, therefore, be even more complicated because some of the uncontrollable parameters like weather and sea conditions must be the same in order to compare »apple with apple«.

ISO standards are sufficient to meet the requirements of shipowners for determining the performance of the ship’s engines against that guaranteed by engine manufacturers. However, the permissible error of +/-3 % inherent in the methodology provided by ISO standards often exceeded the savings claimed by fuel saving technologies, rendering a situation reminiscence of the 1980s. Shipowners are again distrustful; it can be difficult to know whom to trust with the myriad of claims while there are no sufficiently reliable and accurate methods to measure the fuel savings.

ISO 3046 and 15550 provide a reliable methodology that served their intended purpose well. The maritime industry should not throw the baby out together with the water. What is needed is more than just to measure the engine performance. What is needed is to measure the change in performance of engines reliably and accurately. The existing ISO standards can be tweak to enable the existing methodology to achieve this goal.

To ensure a reliable and accurate measurement of change in performance of engines, two issues need to be addressed, namely:

• effects of weather and sea conditions;

• good repeatability and accuracy.

Measurement methodology

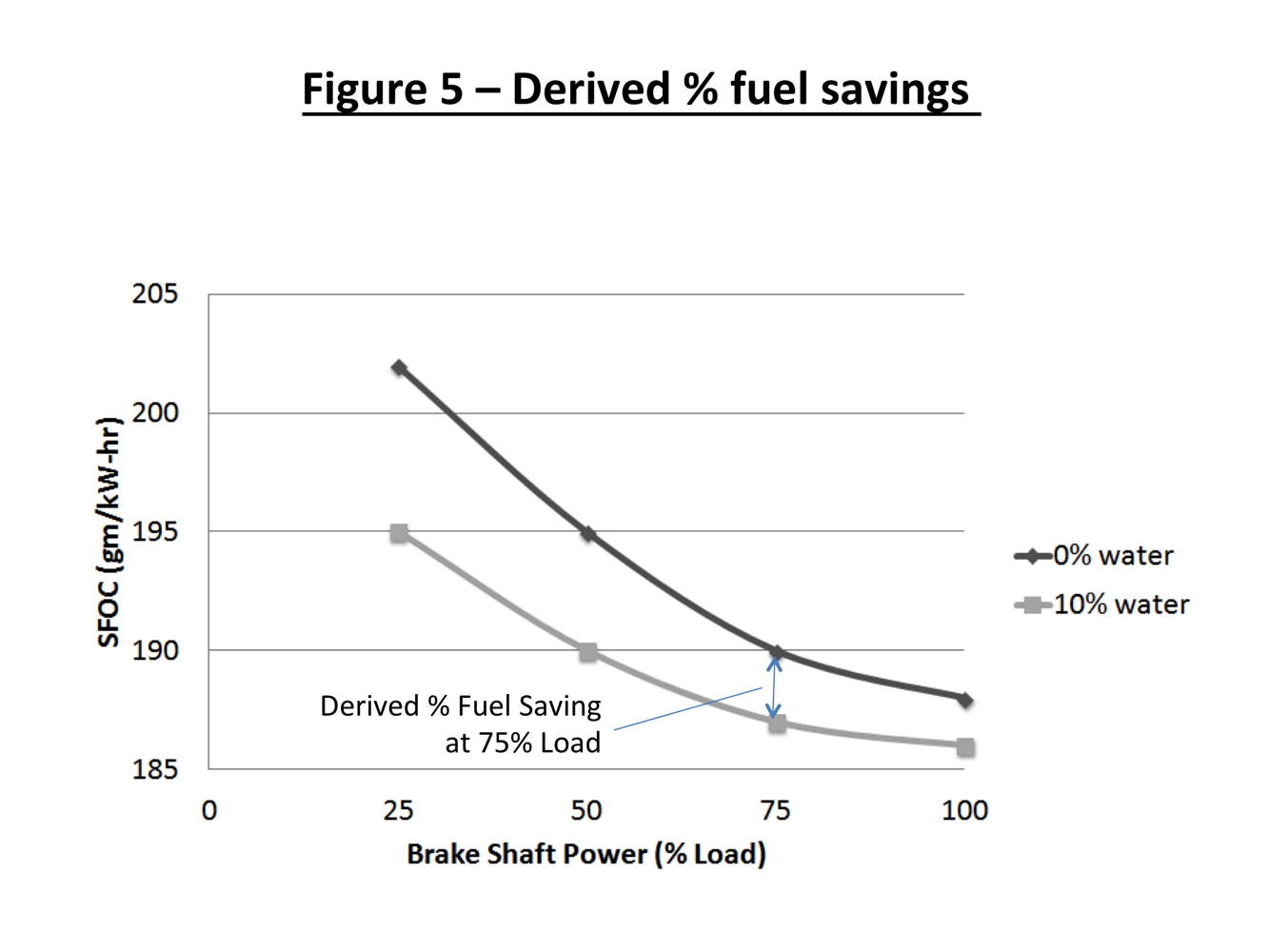

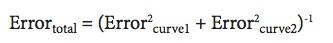

The common practice of improvement measuring is to determine first the baseline reference performance curve of specific fuel consumption against power. Then, the new performance curve is determined with the new fuel saving technologies installed. The improvements in performance are then derived from the differences between the two performance curves as illustrated by Fig. 2. There are two problems associated with this methodology. Firstly, the weather and sea conditions may not be the same when each performance curves were measured. Therefore, the results may not be repeatable even when ISO 3046 are applied to correct the test results to the reference conditions. Secondly, with the %-change derived from two performance curves, the errors of the derived change are increased (the increased error is the square root of the sum of the squares of each errors) as illustrated below; which means, the results are unreliable and inaccurate.

Total error of derived % change:

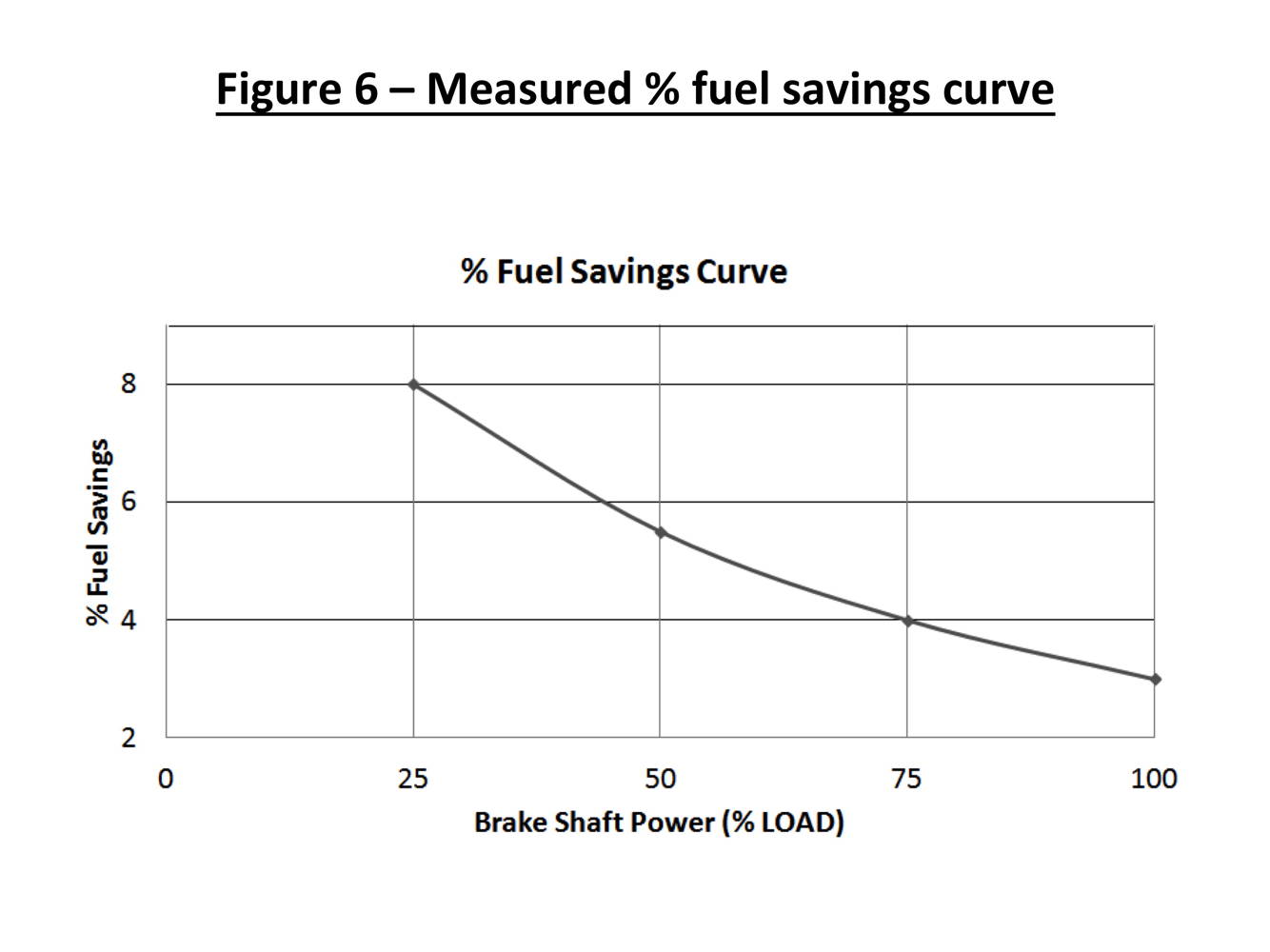

The better methodology adopted by BOS is to measure the percentage improvements directly – instead of deriving them from two curves – with sample size of at least 25 measurements for each power, so that the standard deviations can be used as a reliable and accurate measurement of errors (Fig. 2). The curve of percentage improvement against power is typically plotted by testing at 25, 50, 75 and 100 % load as illustrated by Fig. 2. The complete curve can be plotted in four to five days of testing with proper weather and sea conditions.

As BOS EFS can be switched off and on easily, a single measurement of percentage improvement in engine performance at a particular power (e. g. at 75 % load) can be easily measured directly by comparing the specific fuel consumption corrected to ISO 3046 reference, with the EFS off (i. e. burning neat fuel) and then with the EFS on (burning emulsion). Generally, it takes 10 min to obtain a reliable measurement with BOS EFS on or off and 30 min for the fuel system to stabilize in between switching the BOS EFS from off to on or vice versa. Total time to take one measurement at a particular power is less than one hour. 25 sample sizes are obtained by repeating the measurements 25 times or in about one day.

The big advantage of this method of measuring improvement is that it gives the shipowner a real feel of the improvement in engine fuel efficiency. Shipowners can see the improvement in fuel rates immediately under the same engine, weather and sea conditions, during the tests. This is something the shipowner can trust.

Author: Kaisa Honkanen

Country Manager, Blue Ocean Solutions Finland, Helsinki

kaisa.honkanen@blueoceansoln.com

Kaisa Honkanen