Norwegian Cruise Line’s newest vessel, »Norwegian Breakaway«, was recently christened by the dance ensemble Rockettes in New York. The cruise ship is the largest built in Germany so far and the largest ever called at the American port

After a building period of 18 months the »Norwegian Breakaway« has been delivered to her owner Norwegian Cruise Line[ds_preview] (NCL). She is the twelfth ship for the American cruise operator and thereof the ninth which was built at the Papenburg-based Meyer Werft. Also, she is the largest cruise ship ever built at a German shipyard. The vessel is not stingy at all with superlatives: The top decks feature the first aqua park at sea with five full-size water slides, including twin free-fall slides, and a three-storey sports complex that includes the largest ropes course at sea along with the first ever salt room in the luxurious spa. Furthermore, »Norwegian Breakaway« is the largest ship to homeport year-round in New York, sailing to Bermuda, the Bahamas, Florida, and the Caribbean.

With a hull artwork of America’s popular artist Peter Max showing New York’s skyline, »Norwegian Breakaway« was designed as New York’s ship inside and out. It is thus not surprising that the famous show dance ensemble Rockettes was chosen to be godmothers. The christening took place on 8 May in Manhattan in front of more than 4,000 guests. »The arrival of the ›Norwegian Breakaway‹ is another proof of the growth and success of New York City’s 200 mill. $ cruise sector, a cornerstone of the City’s 55 bill. $ tourism industry,« said Mayor Michael R. Bloomberg.

Technical advances

»Optimization was the key word in building,« NCL’s Newbuilding Vice President Christer Karlsson pointed out. »Taking as a given that we will operate at the same speeds as we always have done, the new ships will be some 20 % more fuel-efficient per passenger transported than those of the past.« Much of this improvement is due to the optimization of the below-water hull as well as the optimized speed. Moreover, the latest generation of silicon-based antifouling paint has a share in reducing emissions.

In close cooperation with the yard an energy management system was developed which includes a heat recovery system through a waste heat exchanger and a new type of sludge recovery system that will recover sludge and after processing the sludge is transported back to the bunker tanks. Heat recovery is implemented on the freshwater and diesel generators. These heat exchangers (four Aalborg XW waste heat recovery boilers) along with waste heat ex-

changers from the main engines can be used in other sources on board, such as the production of fresh water (Alfa Laval’s Multi-Effect Plate evaporator). With regard to sludge recovery, Alfa Laval’s waste oil separator PureDry has been installed. »Instead of burning or landing our sludge we can take care of it in a much better way and even put some of it back in the fuel tanks,« Karlsson said. This represents an average of some 100,000 $ a year in savings. In addition to PureDry, Alfa Laval delivered its bilgewater cleaning system PureBilge, providing cleaning performance in real-life conditions of 0–5 ppm oil content without chemicals, absorption filters or membranes. As the first ship in NCL’s fleet »Norwegian Breakaway« has a ballast water treatment system, also delivered by Alfa Laval: PureBallast.

Moreover, NCL is the first cruise line to install a galley energy management system, known as GEM, from Almaco. The system will automatically turn on the ship’s ovens at scheduled times, allowing the chefs to better manage their kitchens throughout the day and further increasing the energy efficiency. A remote control system for the staterooms allows power, air conditioning and lighting to be switched off remotely when guests are not in their staterooms. The majority of lighting in the public spaces of »Norwegian Breakaway« is LED.

Features on the bridge include a trim optimization system from Eniram that collects data over time and optimizes the trim at different loading and speed conditions, while taking weather and wave elements into consideration. In addition, the NAPA voyage optimization system helps to plan the ship’s cruise in more intelligent ways, such as taking currents, engine configuration and weather into account.

Propulsion

The vessel is equipped with a new generation of ABB XO Azipods that are smaller and more streamlined. Together with a new Azipod Dynamic Optimizing system they enhance the steering and turning angles and thus lead to savings in fuel and reduced emissions.

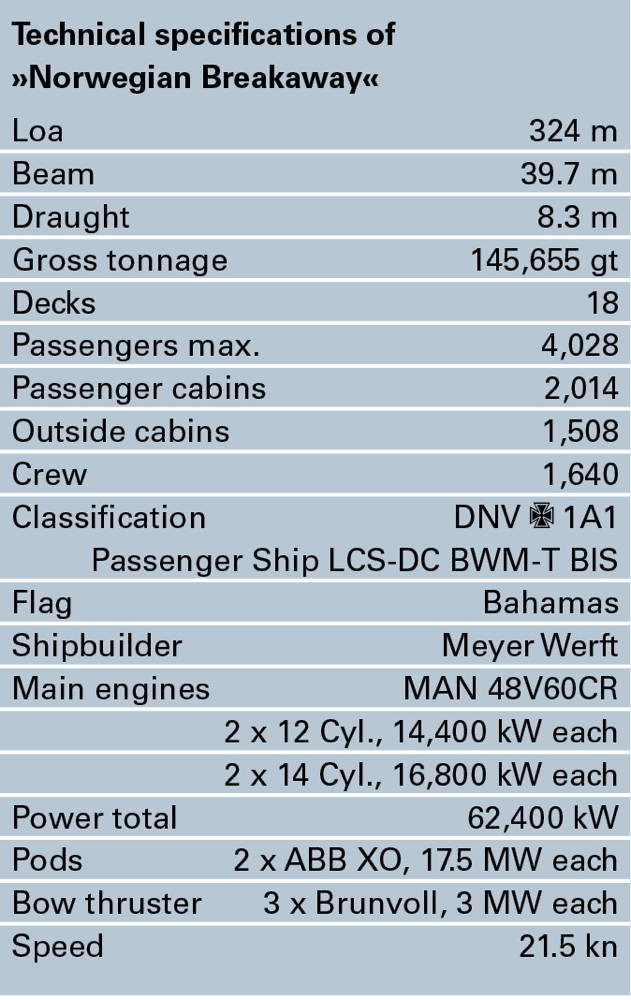

»Our latest newbuilding, the ›Norwegian Epic‹, has got a shafted propulsion system, but now we feel that pods are the right solution for us,« commented Karlsson. Together with the asymmetrical »X-tail« fuel savings of about 4 % compared with more traditional solutions could be achieved. Each of the two Azipods delivers 17.5 MW propulsion power. On board are four MAN 48V60CR main engines rated at 14,400 kW and 16,800 kW, providing a total installed power of 62,400 kW.

Further ships from Meyer Werft

The sister ship »Norwegian Getaway« is scheduled for delivery in January 2014. She will then be the largest ship with year-round homeport in Miami and sail the Eastern Caribbean. In October 2012, NCL has also ordered a »Breakaway Plus« ship planned for delivery in October 2015, with the option for a second ship for delivery in spring 2017. With 163,000 gt and space for approximately 4,200 passenger berths, this newest ship will be even larger than the »Breakaway« class vessels.

NCL/KW