Bluedrive Plus C is a new fuel-saving propulsion system that sets higher environmental and operating standards for offshore vessels. It produces less emissions than today’s conventional diesel-electric or gas-powered solutions, writes Odd Moen from Siemens

In the mid-1990s, Siemens introduced new-generation electric propulsion for offshore vessels based on the latest developments in power[ds_preview] electronics. After successful implementation in the offshore vessel »Skandi Marstein«, the market began to favour electric propulsion systems. In the years after, the company pushed the technological limits further by developing new products that increased shipowners’ profitability. These include several concepts and »world firsts« that still deliver outstanding operating performance today.

Challenges create new technology

By 2000, Siemens was ready to tackle the challenge of optimising high speed diesel engines in the complete electric propulsion plant. The key issue was a low moment of inertia, which made it hard to adjust generator voltage. In turn, this led to generators hunting for reactive power from one another. A second significant issue was vibration. As part of an electric propulsion plant, the engines’ vibrations caused a number of problems, such as fatigue fracture in the common base-frame of the engine and generator, broken bolts and damaged bearings.

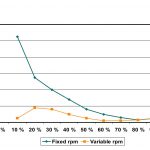

The answer was new technologies that slowed down diesel engine speed when low power was required. The aim of the new system was to obtain better operational performance and lower life-cycle costs by reducing diesel engine maintenance and avoiding hunting of reactive power.

The environmental factor

In the last decade, focus on the environment has become ever important. More environmentally friendly vessels with lower emissions and better fuel economy are becoming the order of the day. As an answer to this issue, Siemens improved performance and reduced life-cycle costs with variable speed diesel engines that optimise the vessel’s operation.

As the company was developing its new systems, Norwegian shipowner Østensjø Rederi, specialist in offshore support and towage, was looking for a more environmentally friendly offshore vessel than the expensive dual-fuel operated options on the market. Østensjø generated a study to compare fuel consumption, greenhouse gas emissions, cost implications and investment for four engine types:

• fixed speed diesel engines

• dual-fuel engines

• gas engines

• variable speed diesel engines

The study showed that variable speed diesel engines achieve impressive savings in fuel consumption and emission of all greenhouse gases. The results were verified by SINTEF Group’s Norwegian Marine Technology Research Institute.

Fuel and greenhouse gas reduction

The new variable speed diesel propulsion system from Siemens studied by Østensjø Rederi reduces total energy consumption by 15 % compared with earlier diesel-electric systems and 23 % compared to gas/dual-fuel engines. Total NOx and greenhouse gas emissions are lower compared with vessels using conventional diesel-electric or gas-powered solutions.

Most satisfying is a comparison with the results of dual-fuel driven offshore vessels with the same operating profile, which are given CO2 fee exemption due to their environmental profile. Calculations show 27 % lower greenhouse gas emissions for the variable speed diesel engine alternative.

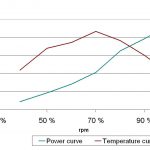

Based on clear results from the research, Østensjø Rederi chose variable speed diesel engines for their new vessel, together with Siemens’ Bluedrive Plus C electric propulsion system. This system allows setting of the lowest possible speed to deliver the highest engine efficiency. To take an example: One medium speed diesel engine operates continuously in the speed range of 375 rpm to 750 rpm to deliver 200 kW to 2,330 kW of power. In comparison, a high speed diesel engine with an operating range of 900 rpm to 1,800 rpm provides power of 350 kW to 1,700 kW.

Increased flexibility

The Bluedrive Plus C propulsion system also gives the flexibility to choose different diesel engine solutions, with regard to engine type, engine numbers and manufacturer, compared to conventional diesel-electric propulsion systems. For example, a variable speed operated high speed diesel engine can be partly operated as a medium speed engine with the fuel economies that follow.

A dynamic positioning (DP) offshore vessel is a good example of a ship that benefits from the new system. When operating in DP mode, power consumption is normally low. The Bluedrive Plus C system slows down diesel engine speed to the most fuel-efficient level at corresponding power. However, speed can be immediately increased on demand. Reduced diesel engine speed cuts noise and vibration across the whole vessel and brings down maintenance costs.

In conventional electric propulsion plants, diesel engines run at speeds that correspond to electric power generation of 50 or 60 Hz. Bluedrive Plus C is completely independent of engine speed to produce electric power at a constant frequency of 50 to 60 Hz. Synchronising the generator set on the main switchboard is non-problematic as well: When the generator is magnetised at lowest operating speed, the generator set is connected and delivers power to the grid.

Power station control system

Bluedrive Plus C controls speed and power of the diesel engines in line with the vessel’s total power requirement. Each engine can be set at different speeds, which means fuel economy is optimised. As only active power is fed from the generators, there are no issues with circulating reactive power, hunting of generators or voltage control adjustments for each generator, as no reactive power is generated.

Diesel engines’ speed and power characteristics are parameterised in the Bluedrive Plus C system according to the manufacturers’ engine type. Bluedrive Plus C includes the power management system (PMS), power plant protection (P3) and the generator power adaption system (GPA). All these systems are integrated in Bluedrive Plus C’s control system to get the lowest possible specific fuel consumption and the highest availability from the electric power station. This secures the vessel’s safe operation and avoids blackouts and other undesirable incidents.

Electric power station

The company’s generators are designed to operate at the same speed and power range as the connected diesel engine. New developments in power electronics make it possible to build the Bluedrive Plus C main switchboard as one unit that reduces the electric power equipment footprint by 30 %. This switchboard incorporates the generator, bus-tie panel, and frequency converters for the main propulsion system and thrusters. Moreover, the bus-tie breaker in Bluedrive Plus C is replaced with a beneficial electronic breaker, which can, among other things, handle unexpected operational situations.

Author:

Odd Moen

Head of Marine & Shipbuilding Norway

Siemens AS, Trondheim

odd.moen@siemens.com

Odd Moen