As a pioneer in this area Propulsion Dynamics explains why and who is already using these technologies

At one time, hull and propeller performance monitoring services that sought to improve ship efficiency were seen as a luxury[ds_preview]. But bunker fuel prices are continuing to rise. According to business consulting enterprise McQuilling Services LLC, bunker prices will hit 760 $/t by 2017. As well, the regulatory environment is becoming less tolerant of polluters and shipping is increasingly coming under the scrutiny of the public eye.

Sustaining the highest fuel efficiency has never been more crucial for shipowners and charterers who want to remain competitive. In-depth performance monitoring is now essential. While there are a number of solutions available that claim to cut fuel consumption and emissions, shipowners and operators, rightly so, want data to prove these claims. And so heads are increasingly turning toward accurate ship performance data and advanced methods of analysis, enabling a shipowner or operator to make better-informed decisions – with quicker returns and greater transparency.

The cost of rough hulls and fouling

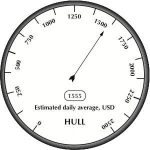

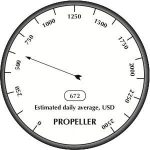

This is where Propulsion Dynamics’ »Computerised Analysis of Ship PERformance« (CASPER Service) has come into its own. It is a mathematical model owned by the US company, whereby its staff of naval architects utilises the model and its interfaces to compare ship service performance data with the clean, smooth hull and propeller performance from sea trials data. This generates data for actual speed and fuel consumption due to basic roughness and fouling of hull and propeller.

Savings in the range of 3–8 % in fuel oil consumption is a realistic goal for companies in the transition from an ad-hoc maintenance scheme into a more sophisticated programme where performance monitoring and performance management is in focus.

Daniel Kane, Vice President of Propulsion Dynamics, says that when it comes to increased ship resistance or speed decay, the split between hull fouling and propeller friction varies between ships. »For some ships one quarter of the performance losses may be due to propeller fouling and three quarters may be due to hull fouling, while for other ships two thirds may be due to propeller fouling and only one third due to hull fouling,« says Kane.

He adds that large containerships will benefit from propeller polishing every three to four months, while for smaller ships every eight to twelve months will yield savings that far exceed the cost of the polishing. »Cleaning of entire verticals of the hulls earlier to remove slime and light marine growth will improve performance 5 % to 15 %, depending on voyage considerations such as time out of dock, coating type, seawater temperature and service speed,« adds Kane.

Implementation

Vessel performance monitoring services are not limited to just one class of ship either. Among the vessel operators using the CASPER system is chemical transport company Eitzen, one of the largest chemical transportation companies in the world, which has been applying the technology since 2008 as the basis for its hull cleaning and propeller polishing programme.

»The performance monitoring has provided the information required to achieve our goals for fuel saving,« says Rasmus Kjaer, General Technical Manager at Eitzen. He adds that empowering the crew to make accurate and meaningful measurements is critical. It brings a heightened awareness of all bridge and engine room conditions, and in turn enables the captain to ensure that the vessel is being operated sustainably.

The environment

It is not just the financial savings that are driving the push to implement real-time ship performance data. Environmental considerations also feed the desire to boost efficiency in maritime transportation. Almost all emissions from ships are reduced when less energy is consumed. Two regulations in particular have forced this sea of change. First there was the International Maritime Organization’s Energy Efficiency Design Index (EEDI), which aims to promote the use of more energy efficient equipment and engines. The EEDI regulations dedicate one section entirely to hull and propeller optimisation. It cites as measures to »significantly improve energy efficiency in the short, medium and long-term«: advanced underwater hull coatings and monitoring; more hydro-dynamically efficient aft-ship, propeller and rudder arrangements; reduced air drag through improved aerodynamics of hull and superstructure; and hull air lubrication systems.

However, it is the Ship Energy Efficiency Management Plan (SEEMP) – an operational measure that establishes a mechanism to improve the energy efficiency of a ship in a cost-effective manner – that is causing the recent surge in real-time ship performance data.

»CASPER is perfect fit for SEEMP,« says Christian Brobeck, Managing Director of Propulsion Dynamics. »By creating a thorough implementation of measures, and continual improvements of technical fuel efficiency, the return on investment is straight-

forward.«

Who is using it?

Traditionally it has been the owner or operator benefitting from CASPER. However, several new shipowners have hired Propulsion Dynamics for continuous analysis of hull and propeller performance in order to satisfy the charterers’ demands for fuel efficiency and »hull efficiency« transparency between owner and charterer.

So, the question is, does investing in real-time ship performance data pay off? Of course, having a system like CASPER in place does not in itself bring any savings – action will need to be taken.

»To gain the maximum potential for fuel savings within the area of hull and propeller performance you need to create a policy describing how and when you will deal with the inevitable maintenance tasks and challenges. The policy needs to define your performance goals and management plan,« says Brobeck. Owners, operators, charterers and even regulators all want greater efficiency, but want to make their operational decisions based on accurate interpretation of ship performance data. It is an investment that is paying dividends.

Contact: Daniel Kane

Vice President Business Development,

Propulsion Dynamics, Long Beach, Calif.

dkane@propulsiondynamics.com

www.propulsiondynamics.com

Daniel Kane