Market leaders have gained a competitive advantage through effective energy management, reveals the latest energy management study. Only a few companies have taken energy management serious yet. Large savings potential remains untapped as the industry is hesitant to explore new paths

Energy efficiency has become a competitive advantage as it has achieved significant prominence throughout the industry. This is one of[ds_preview] the results of the latest study conducted by DNV GL. A year after SEEMPs became mandatory for the shipping industry, the study aimed at understanding in detail how the industry has handled the need to increase energy efficiency in a challenging market environment. A large number of ship managers, owners and operators running more than 2,000 vessels with a fuel bill of about 25 bill. $ have participated. The results show that not only operators benefit from lower bunker costs. Effective energy management is also reflected in higher utilization and charter rates of ships and therewith benefits also ship managers and owners. Companies that succeed in energy management have gained a competitive advantage.

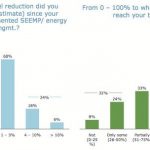

»High savings potential still awaits to be unlocked«, is Julia Kühnbaum’s synthesis on the study she did with her team from DNV GL Shipping Advisory. Leading players already achieved energy savings of 10% and more. The majority of respondents, however, started their activities with low ambition of 2–3% energy savings and finally realized only a part of it. Results indicate that it is these companies, which initially looked for SEEMP compliance only while not spending enough (management) attention to anchor efficiency throughout the entire organization.

Companies succeeding with energy management acknowledge the efforts that are required for successful implementation. »There is a lot to learn from industry best practices in terms of measures, anchoring, monitoring and performance management as well as cooperation with business partners. Even if resources are constraint«, concludes Kühnbaum. According to her, there are a few success factors allowing the leaders to gain the full potential.

– Select far-reaching measures beyond weather routing and engine settings.

Most shipping companies have chosen the obvious, crew related measures as e.g. use of weather routing and adjustment of engine settings, which they can influence fully on their own. The more demanding but also more effective measures which require collaboration with business partners oftentimes remain unexplored. »Many companies are afraid to reach out to partners in the value chain to jointly implement measures. They fear that it negatively impacts their customer relationship. But the opposite is the truth. Making the first step and reaching out the hand to others can secure or improve the market positions«, concludes Jarle Blomhoff from DNV GL.

Analysis of AIS data show that only a few shipping companies focus on optimization of port times, optimized trade planning, improved pro-forma scheduling and realizing constant speed. These measures are powerful tools, that in a team where savings of slow steaming have already been fully captured. Successfully establishing these measures requires a thorough preparation for data analysis, alignments with partners, identification of shortcomings and improvement areas. Lead times are longer and implementation is more difficult, but at the end payback times are less than six months. First initiatives have been set-up to share the benefits of good voyage planning between the different involved parties. The effort it took to align the benefit scheme pays back now with first savings generated.

– Daily management of energy consumption requires smart dashboards

The control of energy is possible only with smart data analysis and transparency. Many shipping companies focus on data collection, but miss out to use the data for detailed analysis as basis for business decision. In addition, the data is not made available to the ones concerned in the organization, to act on daily basis. »Usually we suggest a dashboard solution that has a few individual KPIs per stakeholder group. The dashboard is available on daily basis. A good designed dashboard allows everyone in the organization to see the actual energy performance to act immediately«, states Merten Stein, Project Manager at DNV GL Shipping Advisory. The current solutions available in the market oftentimes still lead to higher individual work load by the ones using it. And they lack intuitive usage. While best in practice performance management systems reduce workload and ease the daily work of shipping companies.

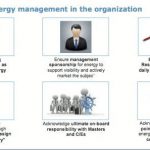

– Energy management needs to be anchored in the organization by assigning clear responsibilities

Typically starting-off in many cases as a project, finally energy management needs to become part of the daily routine. »This is where we struggle most, as no-one feels responsible for energy«, claims a ship operator. Only when energy management is integrated in management systems and part of the individual performance evaluation, the responsibility will be taken up. It is also the responsibility of top management to lead through example. This means energy management and performance reviews need to be part of regular meetings, discussions and communication. Everyone in the organization should be able at every time to answer for what energy KPIs they are responsible, what is the intended target and the current status.

– Supporting employees to adapt to the new world

Every change requires a coordinated change process. It allows crews and onshore staff to gain the relevant knowledge and develop the mind-set to apply the new philosophy and measures. Oftentimes this is neglected completely in shipping companies. Especially when it comes to measures that require change in behaviour the company needs to ensure, that everyone gets enough support to understand what, how and why changes are made. This can be through trainings, newsletters, e-learnings or any other means.

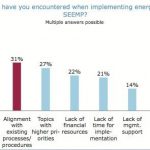

It is also important that all activities described for energy management are aligned with other processes and guidelines. Oftentimes the SEEMP is contradicting or at least not aligned with for example procedures described in the ISM. This leads to increase uncertainty and thus a continuation of »old« habits. Knowing that crews struggle with all the regulations they have to comply with already today, energy might be seen as an additional burden they have to comply with. Accordingly shipping companies should consider streamlining some existing procedures to cap the overall load on the crew.

The industry starts realizing that energy management provides additional benefits other than compliance. Capabilities and time required for success should not be underestimated. Instead, energy efficiency should be embedded as part of the company culture and strategy, and aim at long-term initiatives and goals. »We are happy to share learnings from our study and from our vast project experience in this area« says Kühnbaum.

Pressure to reduce fuel consumption will further increase with new efficient tonnage entering the market. Despite the impact energy efficiency can have, only very few companies have managed to position themselves as true experts in energy management. For those not having accomplished significant savings yet, it will become indispensable to increase fuel reduction. The near future will show who is really determined to master energy management and can turn it into a competitive advantage, and who will falter under the market pressure.

Julia Kühnbaum