Ship owners are concerned about vessel compliance with bilge water regulations. Even with traditional type approved system there are still risks of violating applicable laws and damaging the marine environment.

An new white paper published by Alfa Laval calls for a marine industr[ds_preview]y review of the current bilge water regulatory environment and the need to evaluate test protocols that do not reflect actual operating conditions. Violation of bilge water regulations leads to stiff fines and/or imprisonment for those found guilty of inadvertent or deliberate misconduct. The consequences on the crew and their livelihoods, on ship owner reputations, and on the world’s marine ecosystems are grave, Alfa Laval say in their paper.

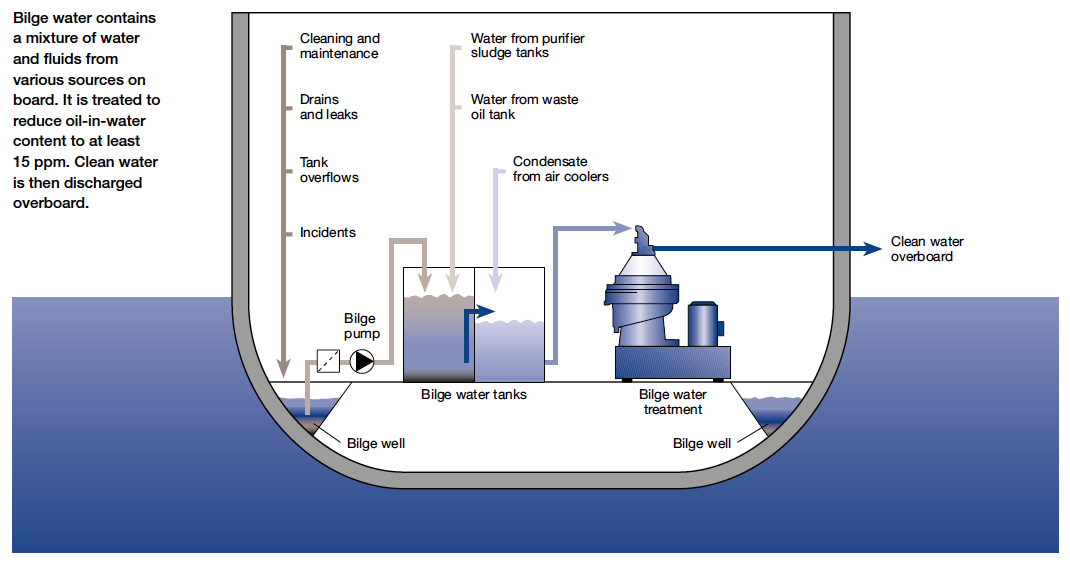

Gravity-based or static separation systems are the most common bilge water treatment systems found on board ships today. These were once considered effective when ships were running on lighter fuels and bilge water contained minimal emulsions. However, gravity-based separation systems are now considered ineffective; they fail to treat the complex cocktail of heavy fuel oil (HFO) mixed with other types of oil and chemicals found in the bilge of modern tankers and other large commercial vessels today.

Static coalescer-type separators only operate at 1 G, a force that is insufficient for breaking down emulsions to meet the mandatory 15 ppm requirement. In a pitching and rolling environment, complex and emulsified bilge water compositions can seldom be separated through gravity alone. This means that additional storage tanks, chemicals and carbon adsorption filters must be used.

Centrifugal separators can cope with complexities

The company says it sees a huge business potential in developing a low-cost coalescer-type separator for bilge water treatment. However, Alfa Laval does not believe that doing so would in any way support the marine industry’s commitment to environmental sustainability. Today only about 10 % of the world’s fleet uses centrifugal separation technology for bilge water treatment. The company clearly sees this technology to be the safest to ensure compliance with regulations. »Vessels operating the IMO-compliant Alfa Laval PureBilge have never been fined for breach of legislation,« Niclas Dahl, Vice President, Marine Separation & Heat Transfer Business Unit Alfa Laval, explains.

Unlike static systems, high-speed or dynamic centrifugal separators operate with a gravitational force of 6000 G, enabling them to cope with the constant motion of a vessel as well as the complexities of modern bilge water. With a long track record of effective performance on board ships, this type of oily waste water treatment system is not sensitive to high solids or oil loads. No additional chemicals are required, and maintenance is minimal. Clean water can be pumped directly overboard thereby negating the need for large bilge water holding tanks.

A recent study published in the journal Nature shed new light on the alarming decline in the dissolved oxygen inventory of the global seas over the past 50 years. This, compounded by the illegal discharge of oily waste by the maritime industry, does not bode well for the future of the planet. Most of the Earth’s oxygen comes from phytoplankton, tiny plants that live near the surface of the seas.