Ballast water related news have been dominated by contracts and agreements lately, but there is still movement on the technology side as the final installation deadlines come closer

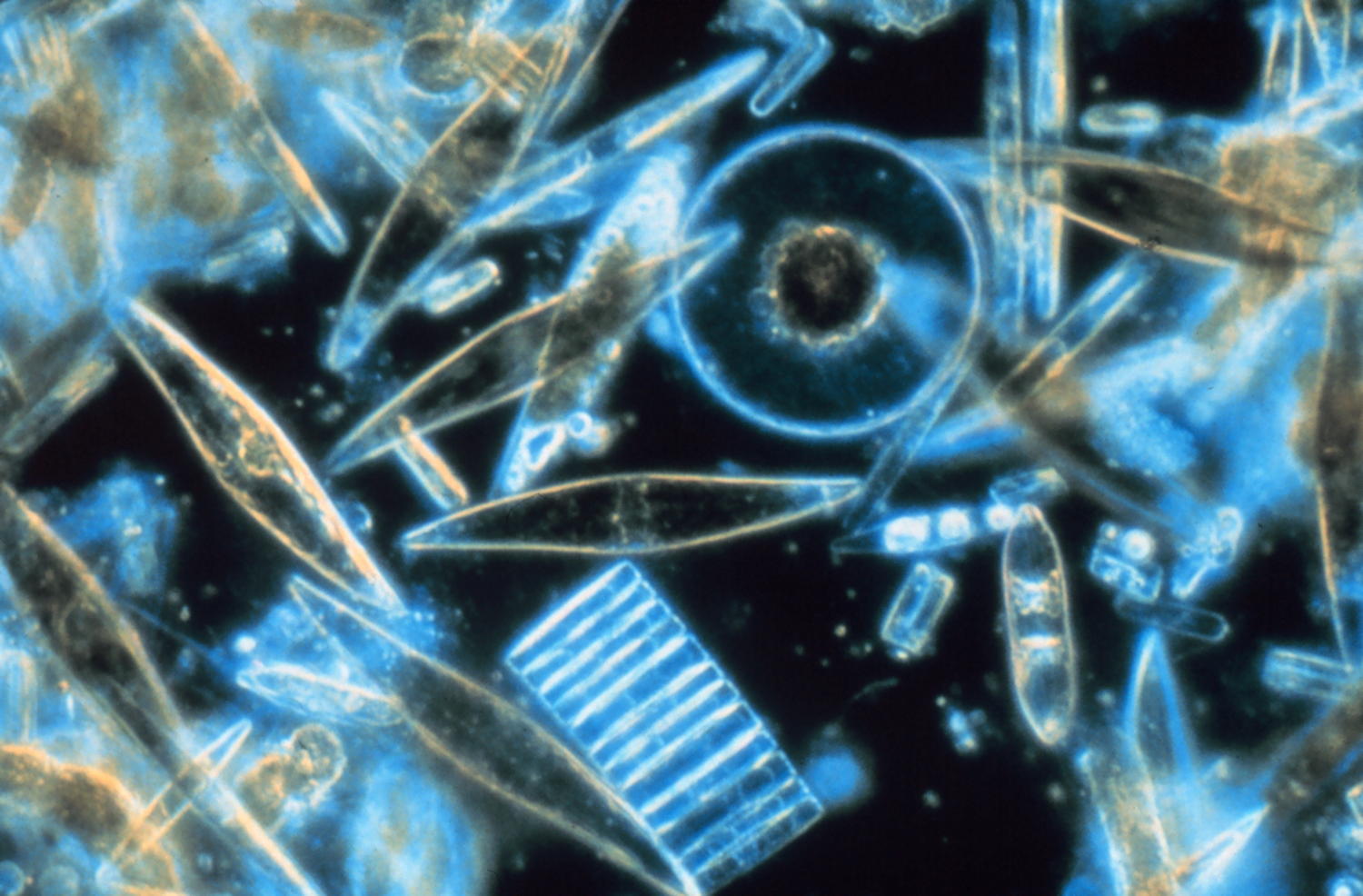

Different disinfection solutions like UV, electro-chlorination, chemical, have all found their place in the market. Now it seems to[ds_preview] be all about choosing the right system for individual needs and meeting the deadlines. Until early September 2024, all existing ships will have to have a ballast water treatment system (BWTS) on board to comply with the IMO’s Ballast Water Management Convention (BWMC). Regulatory bodies and flag state administrations as the Liberian Registry are aware of the difficulties shipowners face to meet the deadlines for installing systems to meet the D-2 standard upon renewal of their IOPP Certification. »We foresee and predict an upcoming bottleneck on the progress of these installations, as the availability of the shipyards to install the systems becomes overextended, yet essential for advancement, in order to meet the standards set by the MARPOL Convention,« the registry says. Liberia will continue to work with shipowners to ensure they are able to comply by their due date, »and with regards to the large back-log brought about by the Coronavirus outbreak, Liberia requests the kind understanding and considerate response from coastal states in respect to this serious issue that shipowners are facing today.«

In the meantime, engineers keep themselves busy by refining their solutions. Danish manufacturer Bawat presented a new OPEX-neutral BWTS. The system has been granted IMO Type Approval. It uses only a ship’s own waste heat from the main engine or other heat sources to neutralise through pasteurisation any organisms in the ballast water. It does not require any chemicals, filters or energy consuming ultra-violet lights. By pasteurisation, the system can be used to treat ballast water in all water conditions, regardless of salinity, turbidity and temperatures, and has no holding time restrictions. Water is treated in one pass only, Bawat says. The company also stresses that the system is unique as components (e.g. heat exchangers, pumps) are all standard parts found on vessels today.

Alfa Laval has recently come up with its PureBallast 3 »bulker-fit configuration«. Bulk carriers have a unique ballasting and de-ballasting profile, because they load and unload at significantly different rates. The new configuration addresses this issue by independently dimensioning reactor and filtration capacities. Since the filter stage is only needed during ballasting, it is dimensioned for the slower flow. This not only reduces OPEX and the system footprint, but also eliminates ballasting overcapacity and a substantial amount of investment cost. The bulker-fit configuration is part of Alfa Laval’s wider strategy in ballast water treatment, which is to provide reliable compliance with the fewest limitations – in installation as well as operation. Increasingly, that means providing vessel-adapted solutions. Besides the bulker-fit configuration, Alfa Laval recently introduced a PureBallast 3 deckhouse solution with booster pump unit, which addresses both space and pressure issues on tankers without a pump room.

Filter first

Damen has unveiled a Ballast Water Pre Filtration Barge (BWPF). Many ports located on rivers experience a sediment level significantly higher than the level on board ballast water treatment systems are tested to (up to 50 mg/l). That can cause filter blockage. The barge is designed to go alongside a vessel at terminal and filter the sediment before ballast water is taken aboard. The barge can process up to 4,000m3 per hour with a sediment level anything between 50 and 1,500mg/l. Filtration is available between 10 and 50 micron, to suit varying sediment sizes. The system fits inside a 40’ container. Damen has also recently introduced the BalCon containerized BWTS that is designed for deck mounting.

Ecospec is meanwhile going for low power consumption BWTS with its ULF Wave Technology, an IMO type approved system utilizing the Ultra Low Frequency (ULF) wave technology. According to Ecospec it is now »the lowest powered G8 ballast water system in its class«. The system is able to pass the challenging tropical waters. Its ability to treat turbid waters where it is impossible without very high power in conventional UV systems is another advantage.

Do it yourself

On the installation side, Carisbrooke Shipping has adopted a novel approach, installing its latest two systems from Optimarin during normal operations, with its own crew, ensuring zero downtime and maximum efficiency and earnings. The firm has just completed commissioning of its second »DIY« installation onboard the »Vectis Falcon«. The »Vectis« ships trade frequently in US waters. Because US compliance dates are earlier than those of the IMO, Carisbrooke had to install the systems before the vessels’ next scheduled docking, so they contacted Optimarin to discuss alternatives.

The initial groundwork involved thorough 3D scanning of the engine room, conducted by specialists Goltens. This provided the measurements that would dictate the positioning of the modular Optimarin BWT unit. Carisbrooke then contacted a Polish manufacturer to make the required piping and foundations and, it was over to them to put in the BWTS. Although Optimarin were always available for remote support, according to Carisbrooke the in-house team didn’t have to call on them once.

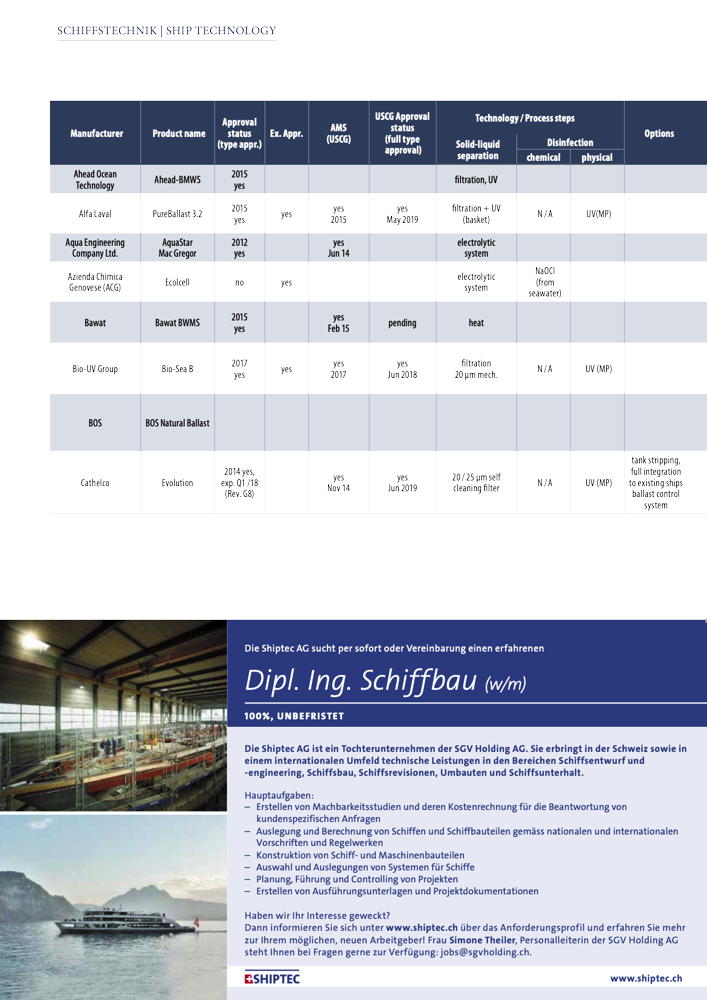

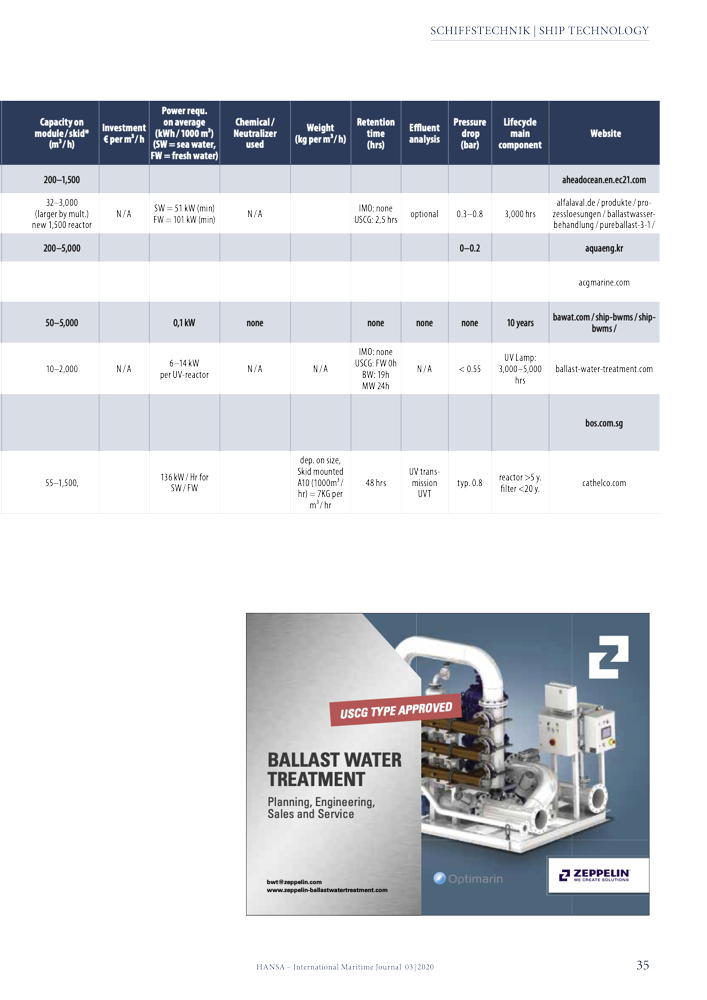

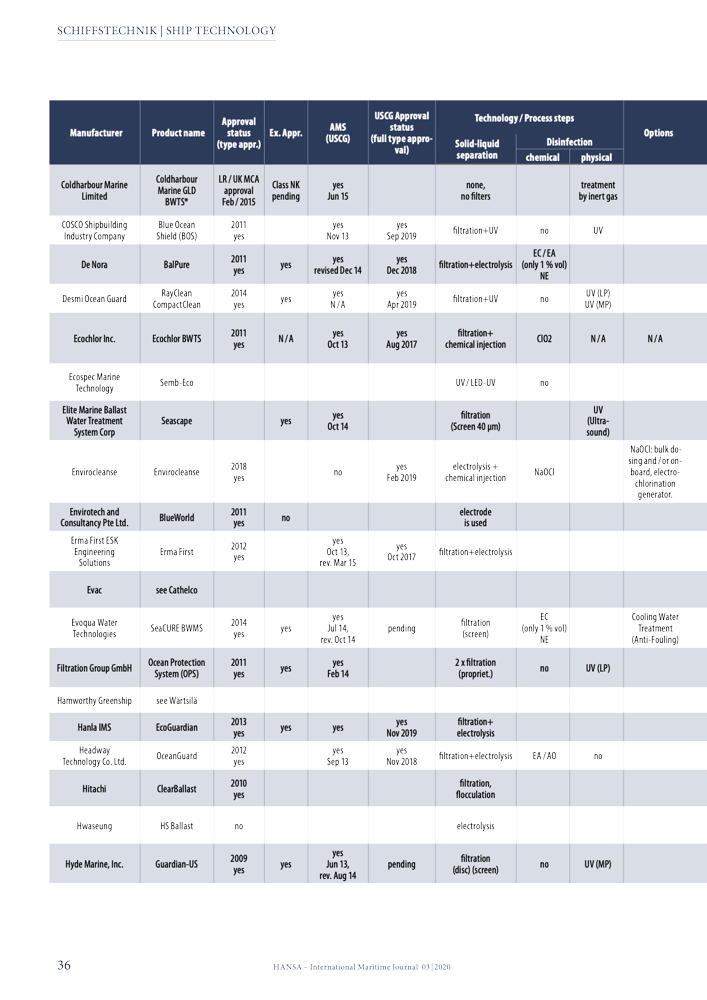

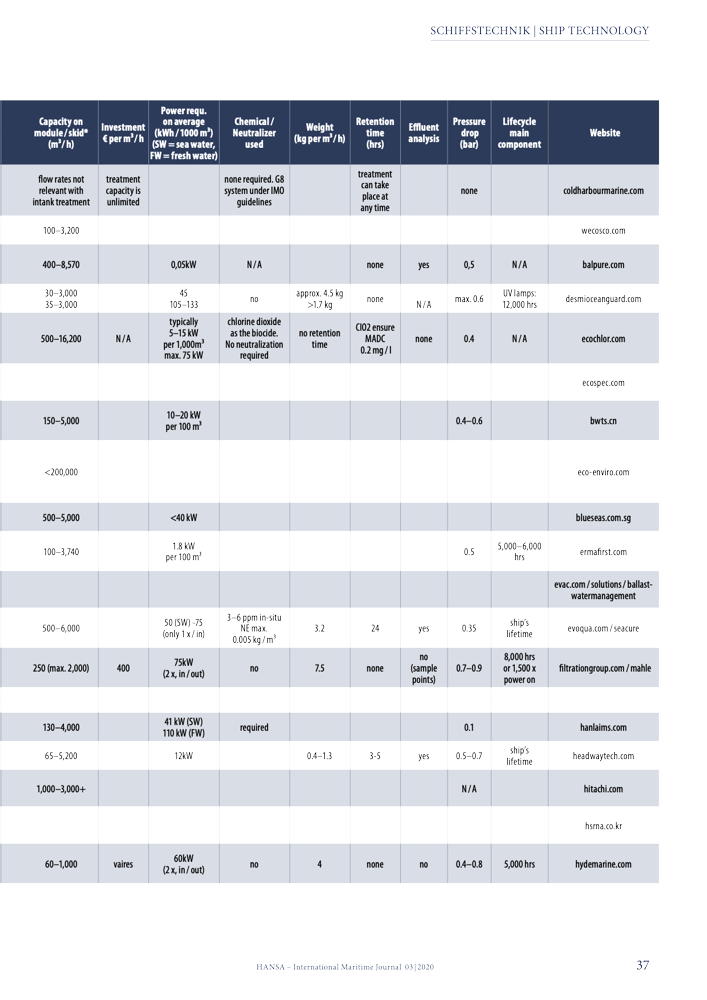

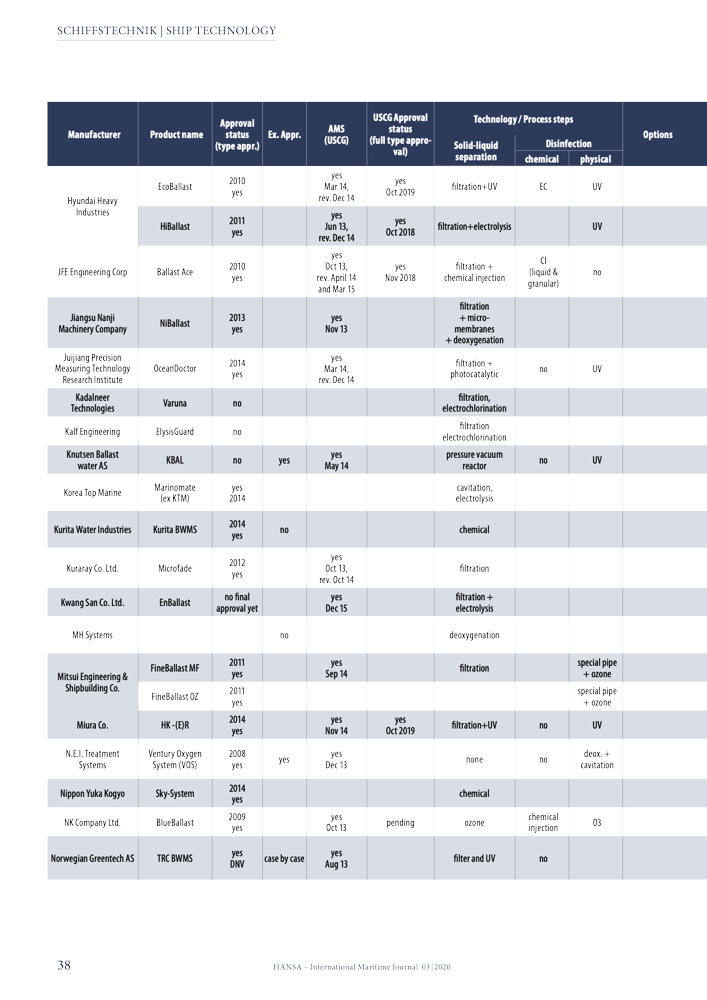

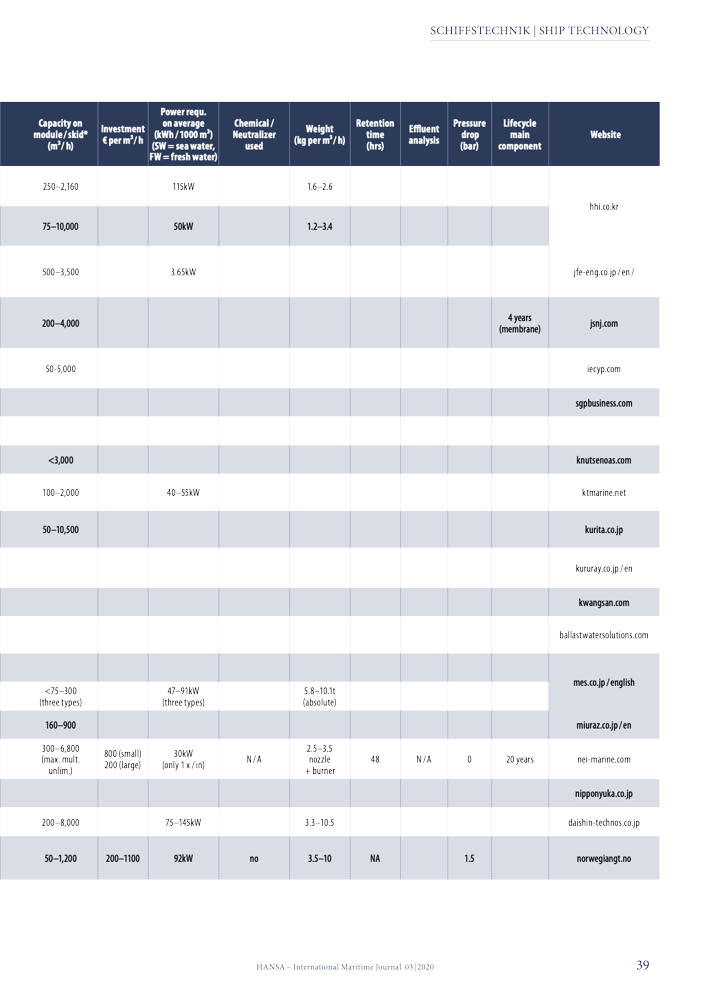

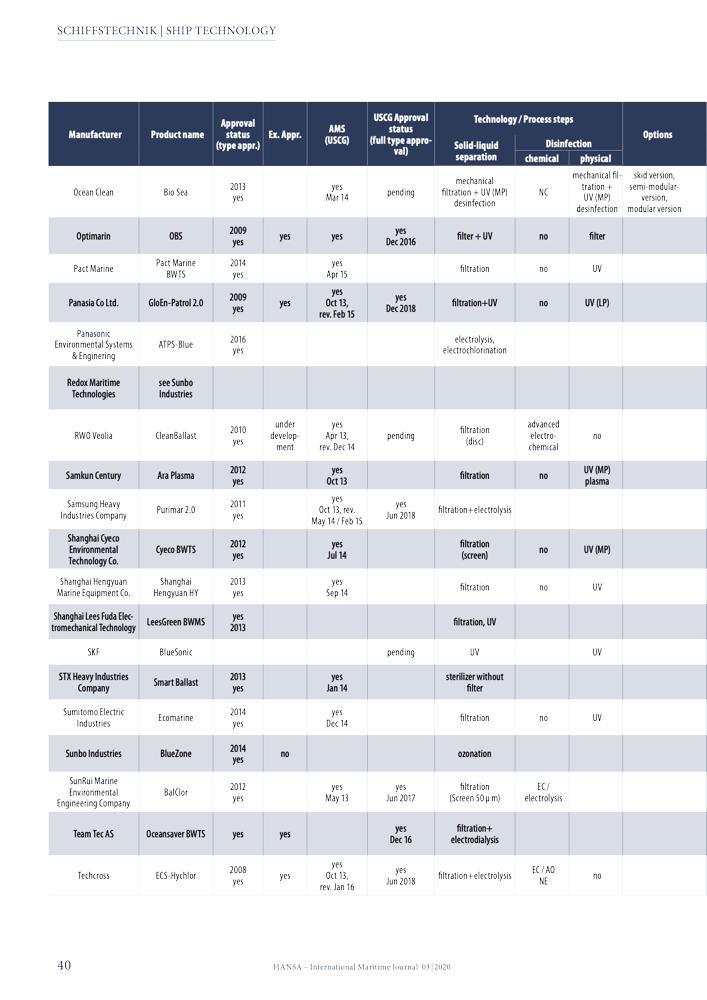

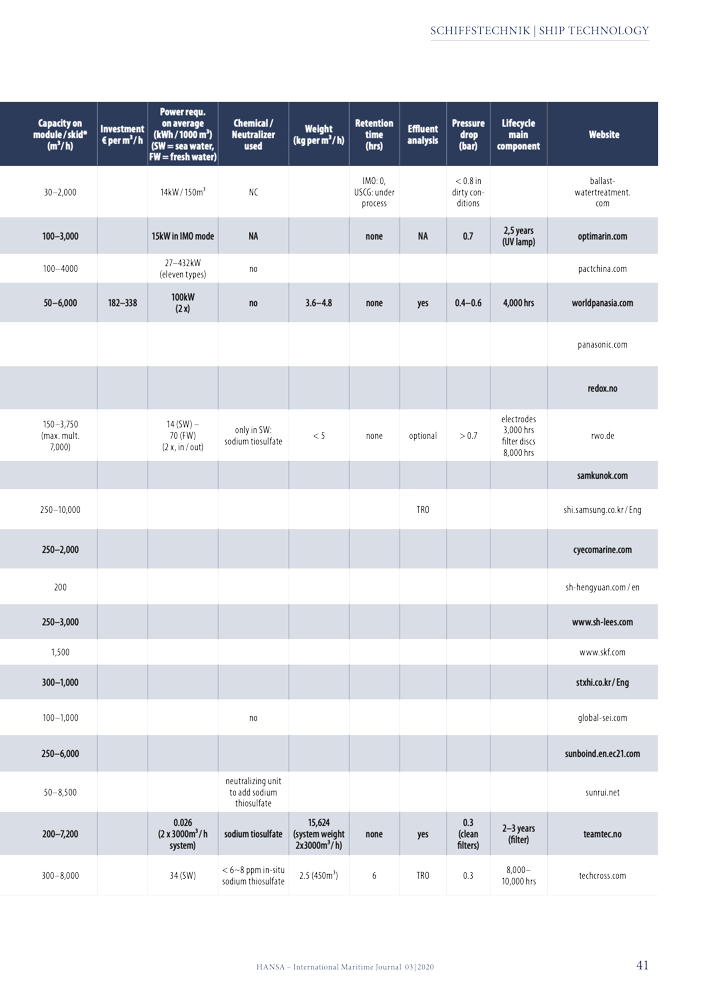

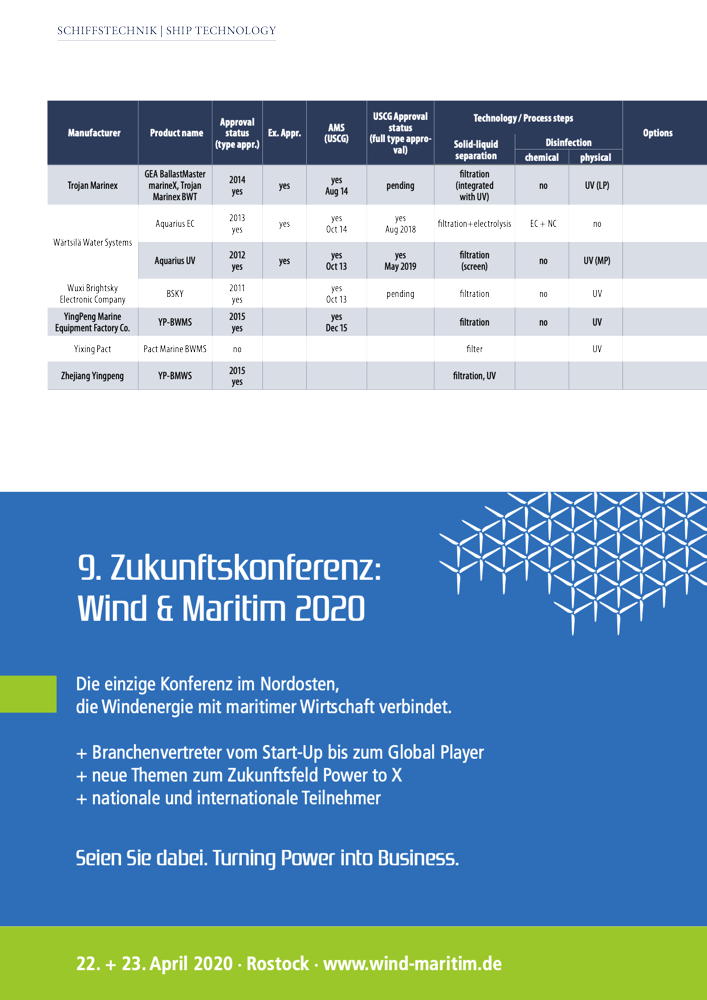

On pages 32-41 HANSA presents a comprehensive list of BWTS manufacturers, products, approval status and specs.