A fuel cell system is an alternative for diesel generators which can offer big emission reductions. However, the implementation of such a system has a huge impact on the ship. Can we indicate this impact and compare if for different fuel types, fuel cell types and hybridization strategies?

The cruise industry is one of the most [ds_preview]carbon intensive segments of tourism with an average emission of 160 kg CO? per passenger per day. As a consequence of the Paris agreement of 2015, cruise operators are facing the challenge to comply to upcoming IMO targets and regulations: a CO? reduction of 40 % in 2030 and of 70 % in 2050 and ECA zones with stringent limits on NOx, SOx and PM emissions.

A fuel cell system is an alternative for diesel generators, which can offer such emission reductions. However, the implementation of such a system has huge impacts on ship size, ship performance, new build price and operational cost.

Design tool

There are different usable fuel types for a fuel cell and there are different fuel cell types. Damen Shipyards and the TU Delft cooperated to map the impact for the different fuel cell systems to evaluate which systems perform best on these criteria.

A design tool is created to indicate this impact. The design tool aims at the earliest design phase; if it is found out later in the design process that the ship will become too expensive or does not reduce emissions sufficiently, a lot of cost are already made.

Practically, the design tool works as follows: the engineer defines main dimensions and passenger capacity. From a database of reference expedition cruise ships a conventional ship is created. With the required power and the required energy to perform its operations, the fuel cell system is dimensioned and placed in the ship. Usually, this fuel cell system is bigger and/or heavier than the conventional system. To fit the fuel cell system the ship size is increased.

However, this increases resistance, energy usage and thus the size of fuel cell system, again increasing the ship size. Consequently, the increase in ship size is an iterative process and can be volume driven or weight driven. This iteration is performed until major deviations from the result are eliminated. This new ship is compared with the conventional ship to find the impact of the fuel cell system. Three hybridization strategies are defined from a functional perspective:

- A full fuel cell powered ship is expected to result in the largest reduction in emissions but also the largest ship and most expensive ship.

- Hybrid option 1: Fuel cells are used for the auxiliary system. Fuel cells fit well with auxiliary power supply since the changes in power demand are lower than for the propulsion demand and fuel cells struggle with high transient loads. The disadvantage is that the vessel cannot operate solely on fuel cells.

- Hybrid option 2: Fuel cells are used for the general operations and diesel generators are used to boost to higher speeds and to fulfil the range requirement.

Which options performed best?

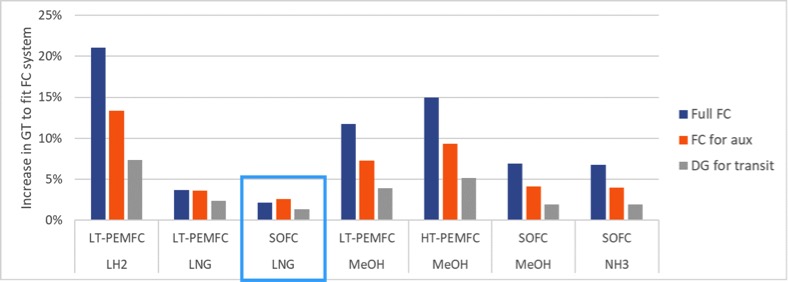

The user of the ship will be very interested in the increase in ship size for the fuel cell powered ship. This can affect the build location or the operational ports. There is a big difference in increase in ship size; the increase in gross tonnage ranges from 2 % to 21 %, dependent on the fuel cell system and hybridization option. LNG fuelled SOFC results in the smallest increase in ship size. This can be explained by the high energy density of LNG and the high efficiency of SOFC.

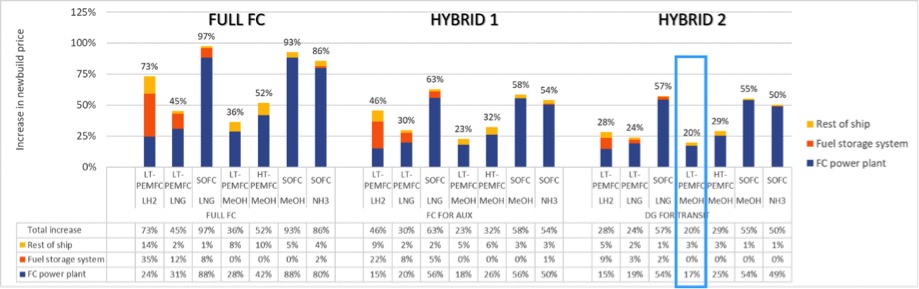

The operator of the ship needs to evaluate whether he can make a valuable business case with such a vessel. It can be observed that the full fuel cell powered ship is more expensive than the hybrid options. Methanol fuelled LT-PEMFC using hybrid option 2 result in the lowest newbuild price.

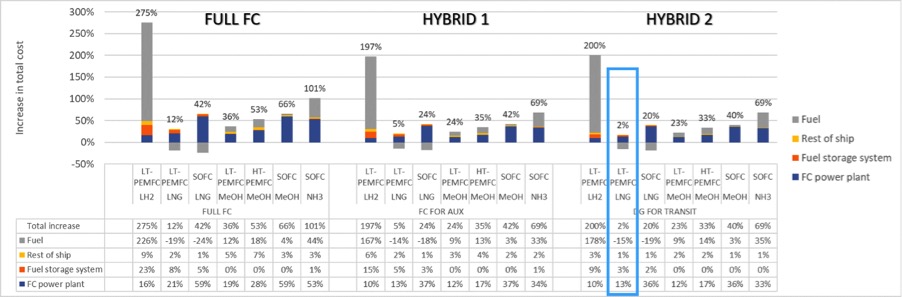

Not only the initial investment, but also the operational cost needs to be considered to judge from the cost perspective of the cruise line. Options fuelled by liquefied hydrogen or ammonia have high fuel cost and results in a high increase in total cost. All options with LNG fueled LT-PEMFC perform best from a total cost perspective, of which hybrid option 2 performs the best.

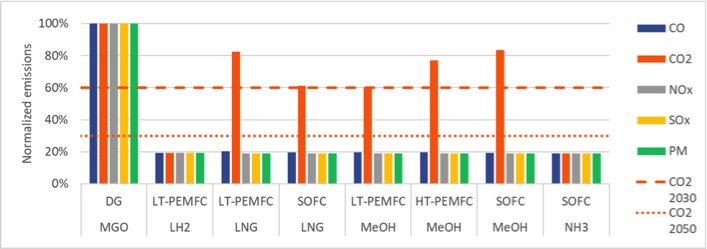

When deciding about such an investment it is very relevant to indicate the realized reduction in emissions. Also, it is necessary to know whether these technologies can comply to the upcoming regulations. If your ship is compliant now but needs an expensive refit in 2030, it might not be worth the investment. All on board emissions are included in the calculation, so emissions by reforming process and fuel cell. The fuel cell system drastically reduces CO, NOx, SOx and PM emissions, but for some options the CO? emissions are still significant due to the exhaust in the reforming process.

The optimal solution

From a newbuild price perspective methanol fuelled LT-PEMFC with hybrid option 2 is recommended. This option is compliant to ECA regulations and meets the CO? goals for 2030. LNG fueled LT-PEMFC with hybrid option 2 performs best from a total cost perspective. This option is compliant to ECA regulations but does not meet CO? targets for 2030.

Finally, it must be noted that no optimal fuel cell system or hybridization strategy can be pointed out. The fuel cell system and hybridization strategy selection are very dependent on the requirements of the customer (cruise line). The cruise line might prefer a ship with a lower newbuild price because it is easier to finance or the customer might even require a full fuel cell powered ship, because the cruise line needs a zero-emission ship. For this reason, the proposed design tool is very useful, because it can be used to evaluate and compare the different options for different designs requirements.

This article is a shortened version of the paper which was awarded the »HANSA Young Innovator Award« during the 12th conference on High-Performance Marine Vehicles – HIPER 2020 (HANSA 11/20, page 56)

Author: Berend van Veldhuizen, Delft University of Technology