Not only due to the number of ships, but also Covid-19 restrictions made 2020 a busy year for IHM-experts. A structured approach is required but can only be achieved under certain conditions

[ds_preview]Until recently, the 2020-deadline for having a certified Inventory of Hazardous Materials Part I, covering hazardous materials in structure and equipment, ships visiting EU or flying an EU-flag was challenging. Most owners achieved compliance within the required time, but a certified IHM onboard is not the final goal as it also needs to be maintained to stay compliant. This entire IHM requirement is subject to frequent controls by PSC, EU-flags and class. The bureaucratic burden and penalties of IHM-incompliance are severe. A structured approach is required but can only be achieved when the scope of IHM including subsequent roles and responsibilities of manufacturers, suppliers, shipyards and shipowners are clear.

Status Quo

Demand for Material Declarations (MD) and Suppliers Declaration of Conformity (SDoC) from the shipowners’ side for maintaining the ship-specific Inventory of Hazardous Materials (IHM) grows rapidly. Suppliers need to prepare and provide those documents, but they struggle as required information from their own supply chains is often not available. Outsourcing this unwanted task is fully understandable for owners and suppliers alike. However, certain service approaches to circumvent responsibilities but offering »best prices« create a perfect compliance-minefield and need to be approached with caution.

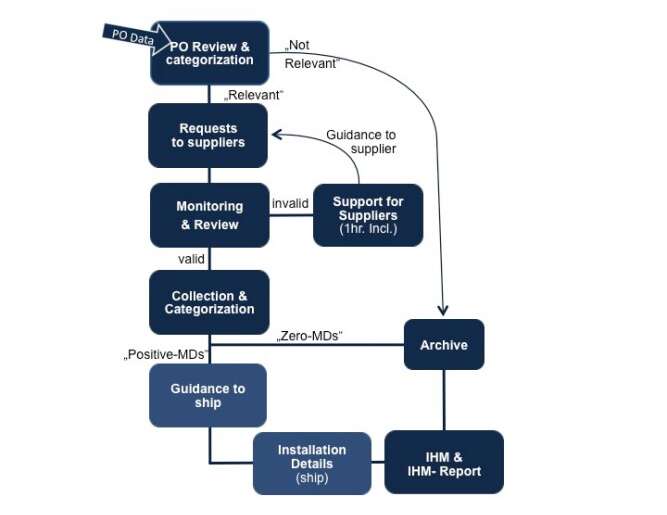

Approaches for IHM maintenance

Some »service approaches« require owners to collect suppliers’ documents and provide them to the service supplier once a month. In the same frequency ships are asked for onboard-changes relevant for maintaining the IHM. Consequently, most of the work, liabilities and time remains with the owner. The service fee and level is low, as is quality of IHM maintenance, but owners remain heavily involved. If this is the service supplier’s approach, it seems to be better for the owner to keep all in his own hands.

Many service suppliers are not selecting relevant order items and copy entire order lists for requesting documents from suppliers. On average, we classify around 5 % of all order items as relevant and therefore avid 95 % of unnecessary requests. Any other approach increases the number of documentation gaps which are to be documented in the report on IHM maintenance. Such avoidable gaps will trigger problems during PSC-inspections and re-certification of the IHM in addition to an unnecessary workload for suppliers.

Another approach is that order or ship-specific documents are requested for items. This increases the documentation efforts for suppliers tremendously and indicates a substantial lack of understanding IHM maintenance principles, as the SDoC is a supplier-specific and the MD a product-specific document.

The worst case observed so far is a service supplier producing order data for each item of an order and ship-specific MD and SDoC, into which the scanned signature of the supplier is copied in. Such documents are sent to the shipowner, even when not requested or for non-relevant products. As it is done within few minutes it is obviously done without requesting information from sub-suppliers. It is only a matter of time until this approach, probably based on a simple software converter tool, will put at least the signatory before a court.

Back to Basics

Owners, manufacturers and suppliers face a new challenge for documenting presence and absence of hazardous materials in products and onboard ships. Other industries have developed principles for material compliance data exchange decades ago which can be applied for IHM maintenance as well. A sound understanding of such principles and adopting them is the key for efficient IHM maintenance. It´s not what IHM-experts have been certified or approved for and different approaches need to be applied.

Authors:

Henning Gramann, GSR

Otto Klemke, NautilusLog

How an efficient IHM Maintenance is achieved will be explained in the next issue of HANSA.