The »Color Hybrid« has now been delivered by Ulstein shipyard and has started operation for Color Line shipping company as the world’s largest ferry with hybrid propulsion. The battery system is the core element

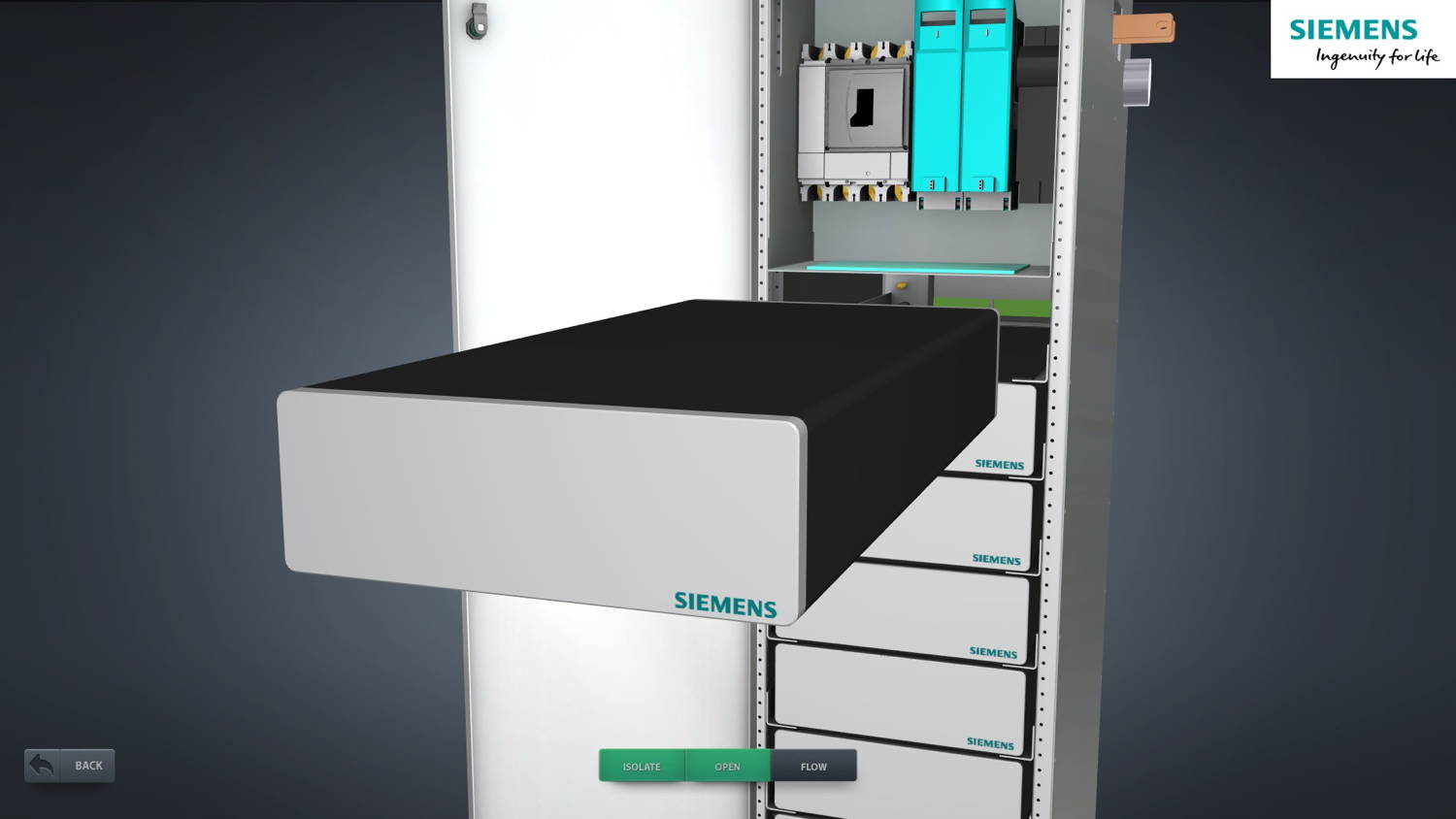

The new ferry uses a diesel-electric plug-in hybrid concept with PTO/PTI, allowing for hybrid propulsion using both[ds_preview] direct-drive and electric. The battery and energy management system came from the German Siemens Group, which used its new factory in Trondheim, Norway, to deliver the order. Blue Vault – the battery element first introduced in 2018 – has been integrated into the »Color Hybrid« as part of the »BlueDrive+C« concept. Although the ship is not the first to be equipped with BlueVault, the entire system had to be adapted to the newbuilding, as Siemens battery expert Torstein Sole-Gaertner explains to HANSA.

78 lithium-ion battery blocks with a total capacity of 4.7MWh are installed in four rooms. The batteries are supplied via direct current (DC) and are connected directly. »In this way, we can reduce energy losses that could not be prevented by the otherwise necessary power conversion, which contributes to comparatively high fuel efficiency,« says Sole-Gaertner. For Color Line, this, in combination with robustness, was one of the decisive factors when choosing a battery supplier. The generators can be operated at variable speeds, depending on the energy requirement.

The concept involves charging in the port of Sandefjord – with »green power«, consisting mainly of hydro power –, which allows the ship to run purely on batteries out of the fjord. Then the system switches to hybrid propulsion on sea and again back to all electric before entering the Fjord again. The batteries are being recharged via a power cable with electricity from shore facilities or, as a secondary alternative, recharged on board by the ship’s generators.

An automated 11KV charging system is installed on board the vessel. The power rating is 7MW. »7MW is quite a high power for such a system. We also have a specially developed system that enables charging and reduces the number of power electronic components«, the experts says.

At vessel speeds up to 12kn, the battery package weighing almost 65t is going to allow for 60 minutes of fully electric operation. In normal operation the vessel’s top speed is 17kn. When running in hybrid mode, the batteries are used to even out the load peaks of the generators. »This is important to run the diesel generator in the most energy efficient way. By doing this, you can minimize the fuel consumption and it also allows the exhaust gas to stay at optimum temperature to be most efficient«, Sole-Gaertner adds. When the system is running in pure electrical mode, the ferry has two times 2.7MW of propulsion power. In this case all gensets are being switched off.

»Color Hybrid« could actually be charged fully in 45 minutes. However, in practical terms, since the vessel is at port for longer time, the power can be reduced and the charging time lengthened to run the batteries more gentle.

One thing which Sole-Gaertner describes as »one of the real differentiators« is the direct cooling of the batteries. Fast charging with 7MW puts quite a strain on the batteries. A lot of heat is generated, that could be distributed to many batteries in a complex process. Siemens and Color Line thus opted for the cooling system. There is a water cooling layer between the cells, so the operators are able to efficiently control the temperature of all the battery cells. Not least, temperature control is extremely important for safety. »You can imagine the heat when charging at 7MW. With our system we can charge at this power for a long time«, Sole-Gaertner says.

The batteries are typically designed for a lifespan of ten years. However, the producer intends to learn much more about the technology during the operational phase and increase sustainability. Siemens hopes to be able to have a second hand use of the batteries after their service at sea. »There are a lot of other markets with less safety and uptime requirements. This is something we are working on,« Sole-Gaertner says.

Siemens’ scope of supply also comprises control systems like the remote control system on the bridge and the integrated automation system of the vessel as well as a 6MW heat accumulator for the battery system. Both electrical motors and electrical generators have been supplied by Siemens, while the vessel’s Bergen diesel engines were delivered by Rolls-Royce Power Systems.